Moulding unit for the manufacture of containers comprising compensation gripper

A molding and fixture technology, used in household components, applications, household appliances, etc., can solve problems such as large mechanical stress, and achieve the effect of good energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Conventionally, the longitudinal and transverse directions are determined relative to the mold base in a fixed manner such that the open or closed position is not affected by these orientations.

[0099] Also, without limitation, the expressions "front" and "rear" are used with reference to the longitudinal direction, "up" and "bottom" or "high" and "low" with reference to the vertical direction, and finally "left", "right" with reference to the landscape direction And "inside" and "outside".

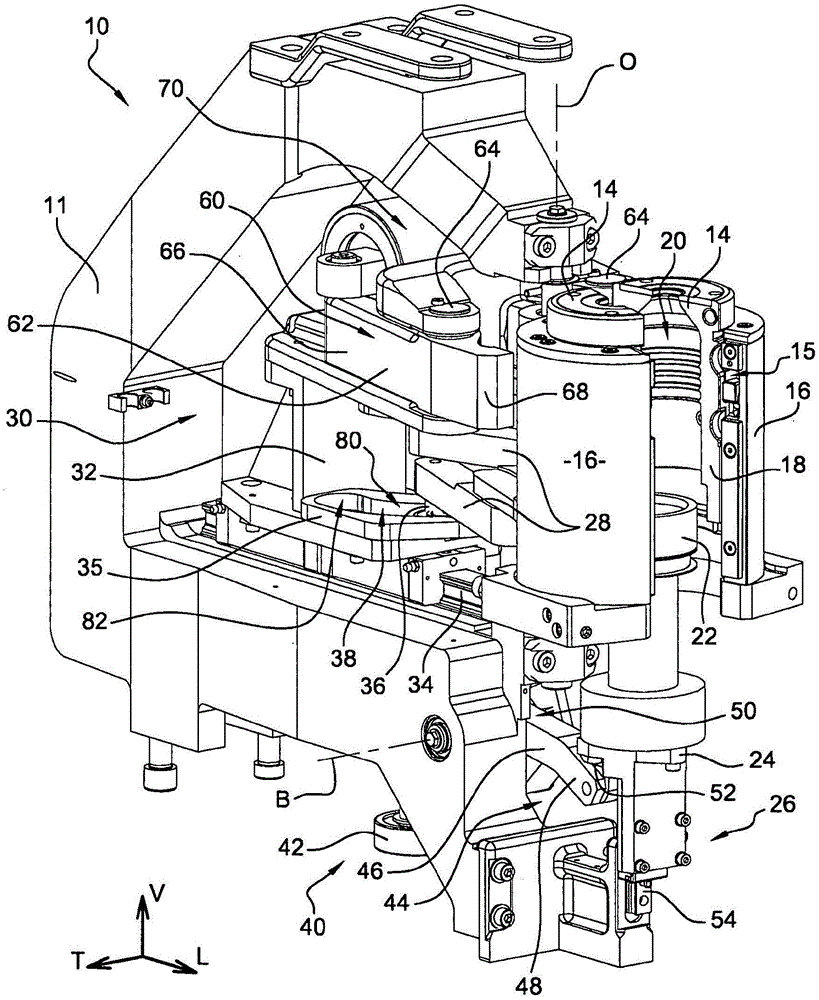

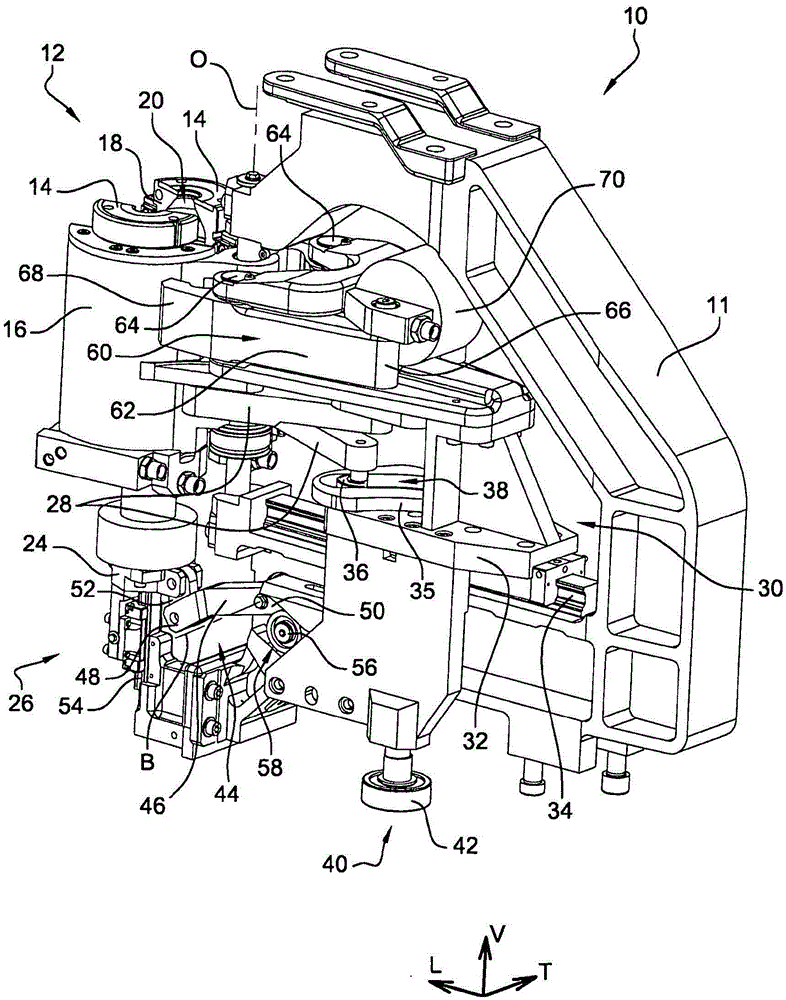

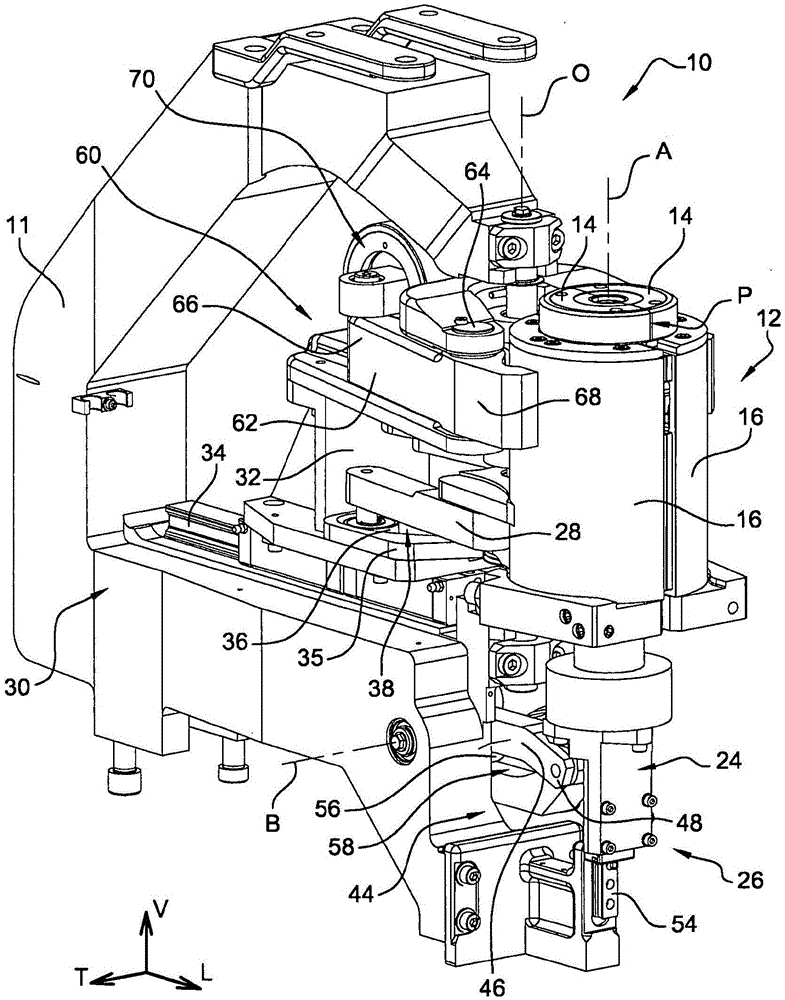

[0100] Figure 1-4 An embodiment of a molding unit 10 for producing containers from preforms of thermoplastic material is shown in FIG.

[0101] The molding unit 10 according to this embodiment is more particularly intended to be mounted on a container making machine (not shown) of the rotary type.

[0102] The molding unit 10 comprises a frame 11 mounted so as to be fixedly connected via the frame 11 to the circular conveyor of the machine, which is driven to rotate around a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com