Composite heat shield for spacecraft reentry body

A technology of spacecraft and heat protection layer, which is applied in the direction of aerospace vehicle heat protection devices, aerospace safety/emergency devices, etc., and can solve the requirements that cannot meet the performance requirements of spacecraft re-entry bodies, limited space body shape, and heat insulation requirements Advanced problems, to achieve the effect of improving thermal insulation performance, reducing thermal conductivity and temperature conductivity, and meeting heat protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

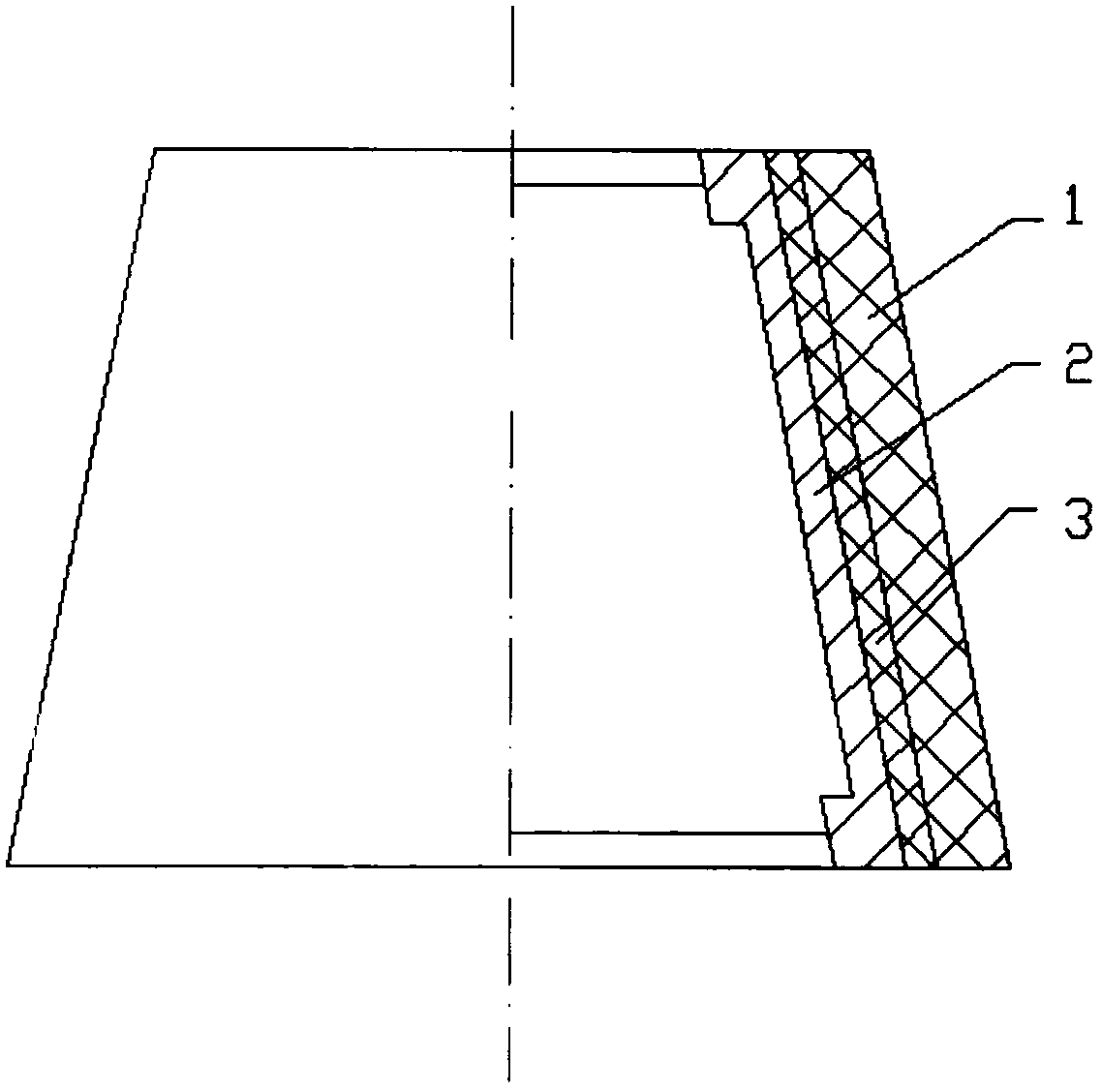

[0058] The composite heat-proof layer of the spacecraft re-entry body in this embodiment includes an ablation layer 1 and a heat-insulation layer 3 added to the ablation layer 1, and the heat-insulation layer 3 adopts a new type of glass fiber reinforced plastic material with hollow glass microspheres , the ablation layer 1 is made of high silica cloth treated with phenolic resin.

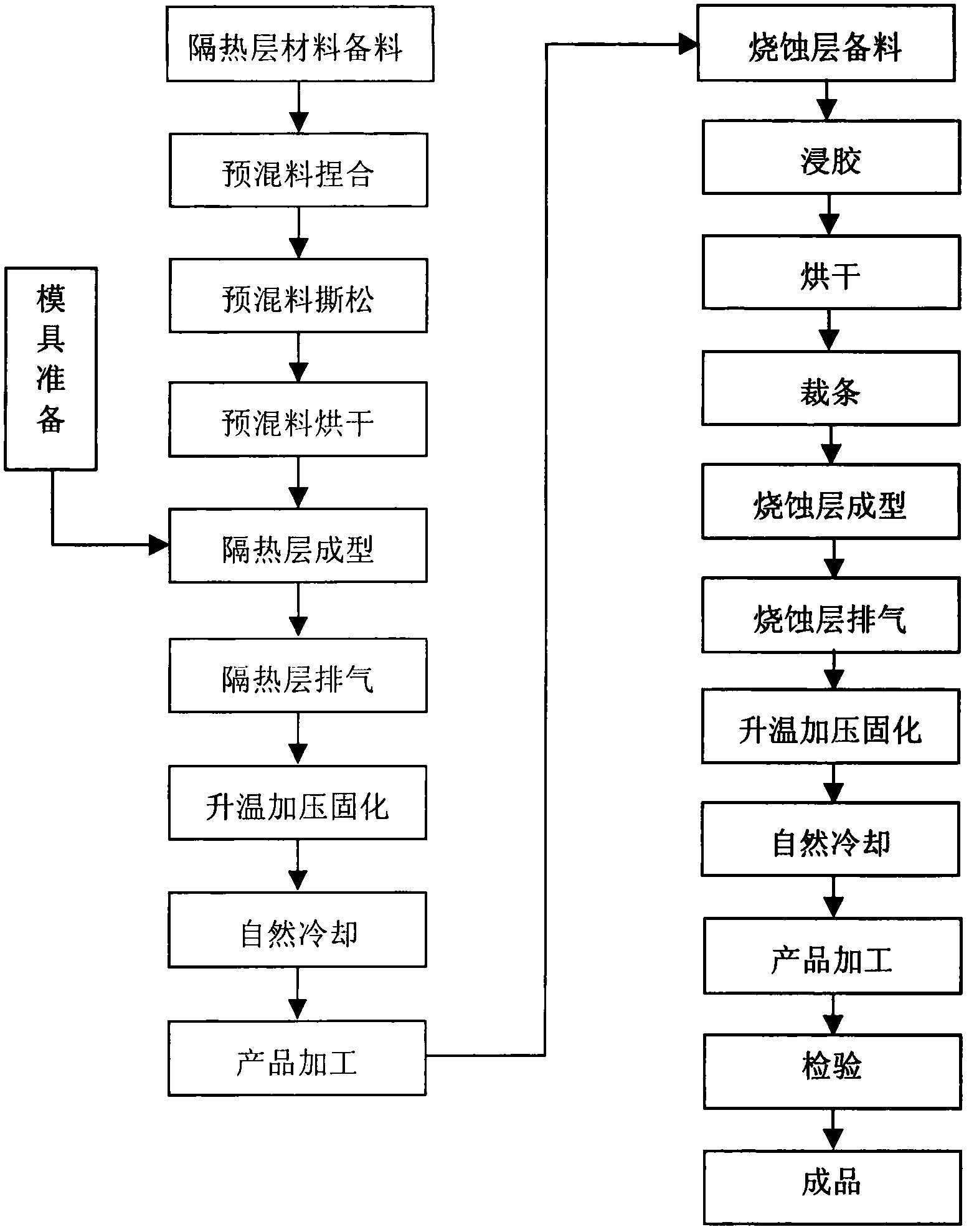

[0059] image 3 The forming process flow of the composite heat-proof layer of the spacecraft re-entry body of the present invention is two layers, and the process is as follows:

[0060] The heat insulation layer 3 is formed by adding a premixed material with a low thermal conductivity function to form a glass fiber reinforced plastic molding method

[0061] ① Mold preparation, prefabrication of a mold that matches the shape of the spacecraft re-entry body;

[0062] ②Insulation layer preparation

[0063] The high-strength chopped glass fiber yarn, resin and hollow glass microspheres are accordin...

Embodiment 2

[0089] The composite heat-proof layer for spacecraft re-entry in this embodiment is characterized in that: the ablation layer 1 is made of phenolic resin pre-impregnated adhesive tape, and all other steps are the same as in Embodiment 1, only the premix formula is different. The forming process of the composite heat-proof layer is the same as that in Embodiment 1. No longer.

Embodiment 3

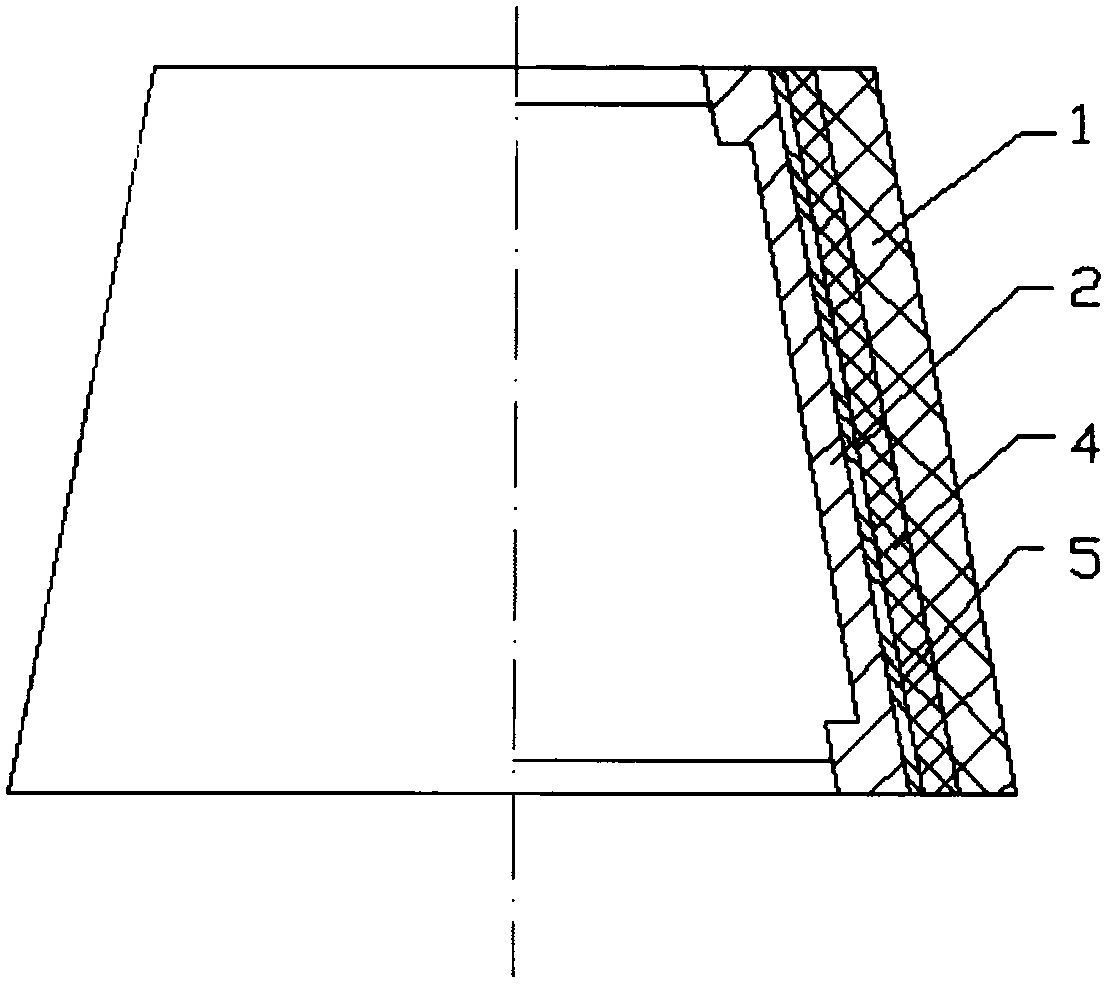

[0091] The composite heat-proof layer of the spacecraft re-entry body in this embodiment is characterized in that: the heat-insulating layer 3 is composed of an inner layer 4 and an outer layer 5, and the inner layer 4 adopts ordinary glass fiber reinforced plastic prepared by a conventional method, and the outer layer Layer 5 is a thermal insulation material, and the thermal insulation material is EPDM film. The ablation layer 1 is the ablation layer of Embodiment 1, and the material is high silica cloth treated with phenolic resin.

[0092] Figure 4 The forming process flow of the composite heat-proof layer of the spacecraft re-entry body of the present invention is three layers, and the process is as follows:

[0093] The inner layer 4 and the outer layer 5 of the heat insulation layer constitute the forming method of the heat insulation layer

[0094] ① Mold preparation;

[0095] ②Materials for the heat insulation layer are prepared. The inner layer 4 is made of glass c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com