A landing probe soft landing mechanism buffer

A technology of buffers and detectors, which is applied in the direction of aerospace vehicle landing devices, elastic shock absorbers, and systems for aerospace vehicles to return to the earth's atmosphere. It can solve the problems of insufficient energy absorption, sensitivity to temperature changes, and difficult applications. problems, to achieve the effect of ensuring safe landing, stable performance and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation process of the present invention will be further described below in conjunction with the accompanying drawings:

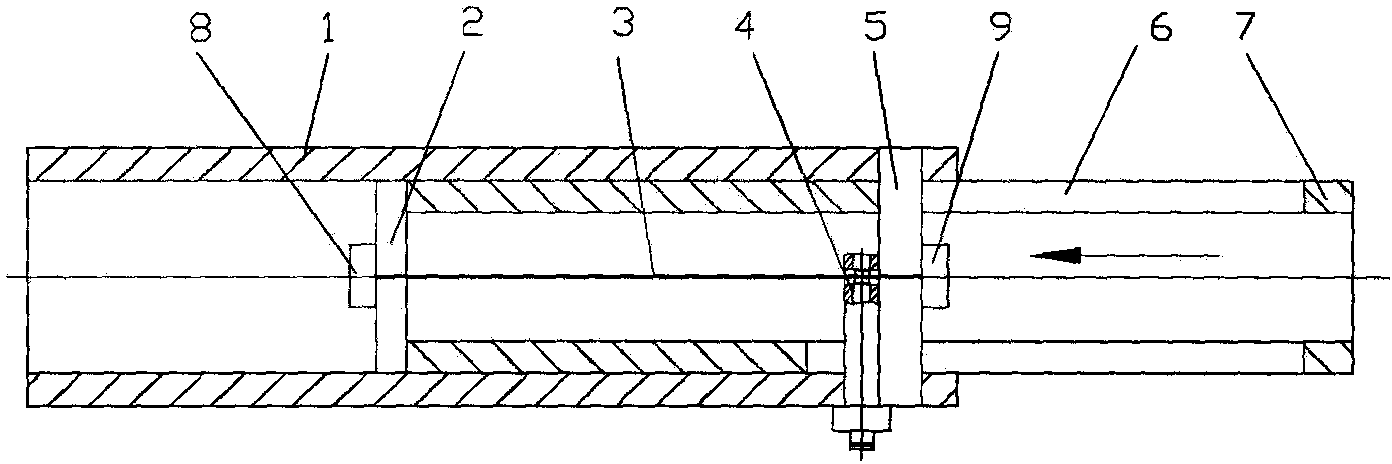

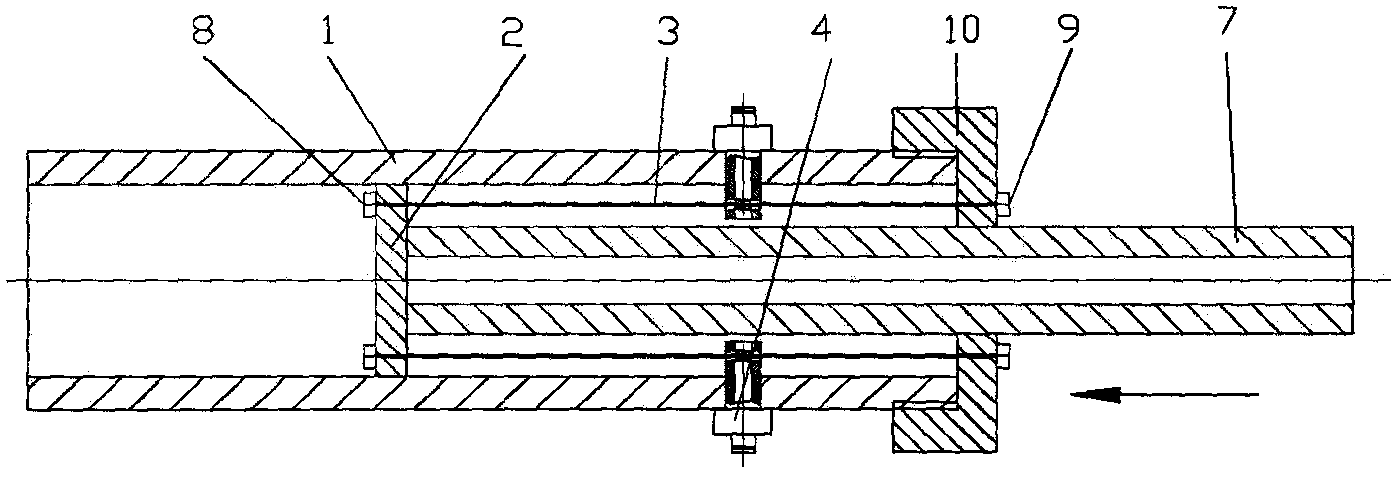

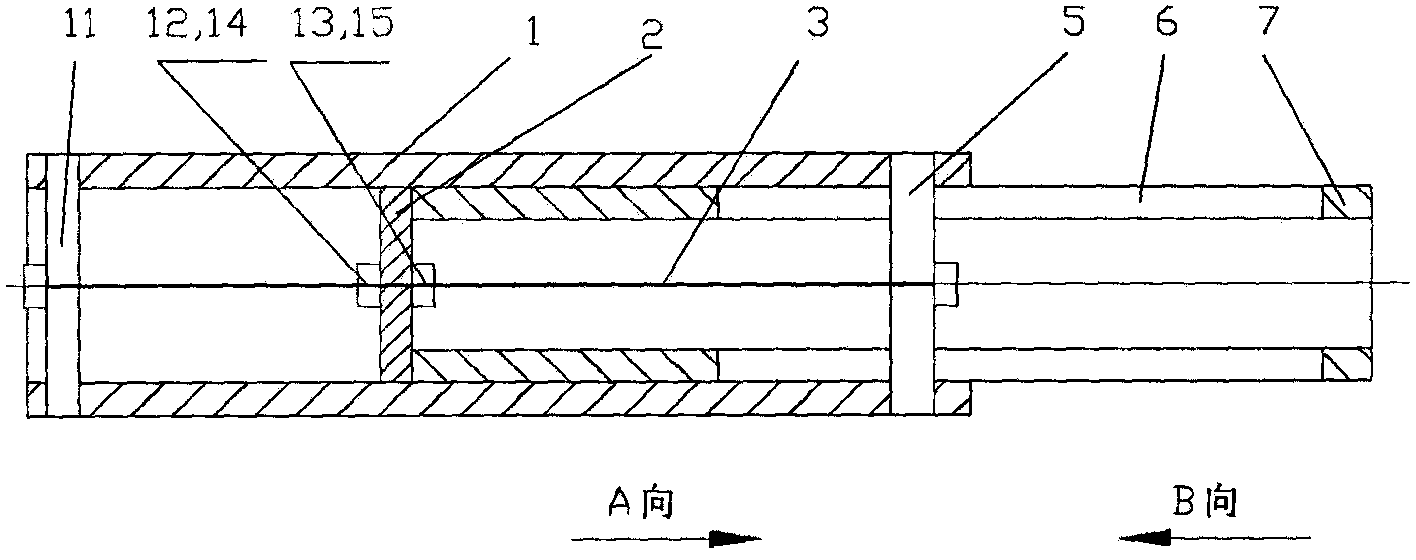

[0017] Such as figure 1 As shown, the present invention is a piston structure, which mainly includes an outer cylinder 1, a support plate 2, a metal tie rod 3, a cutter 4, a support rod 5, a "1" groove 6, an inner cylinder 7, a nut 8 and a nut 9.

[0018] The support plate 2 is integrated with the inner cylinder 7, and the inner cylinder 7 has a "1" groove 6, the support rod 5 passes through the "1" groove and is connected with the outer cylinder 1, and the two ends of the pull rod 3 are threaded , the nut 8 and the nut 9 are tightened between the support rod 5 and the support plate 2, and the cutter 4 is connected with the outer cylinder 1 as a whole. When the soft landing mechanism works, the inner cylinder 7 moves in the direction of the arrow, and the tie rod 3 is pulled. When the tension reaches its yield limit, the metal ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com