Humus treatment all-in-one machine

An all-in-one machine and humus soil technology, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of large space required, poor treatment effect, and inability to easily prevent heat loss, Effect of preventing gas leakage and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

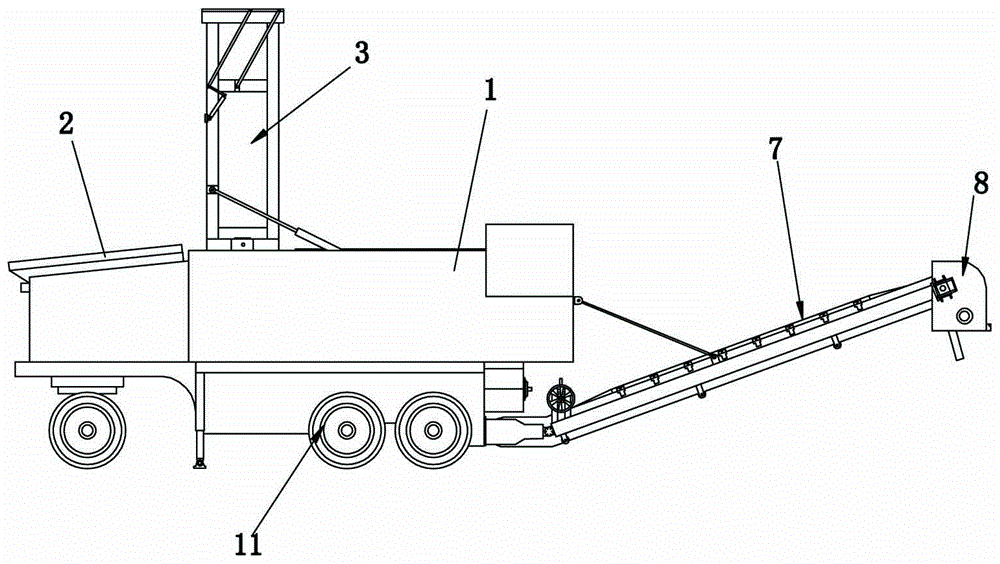

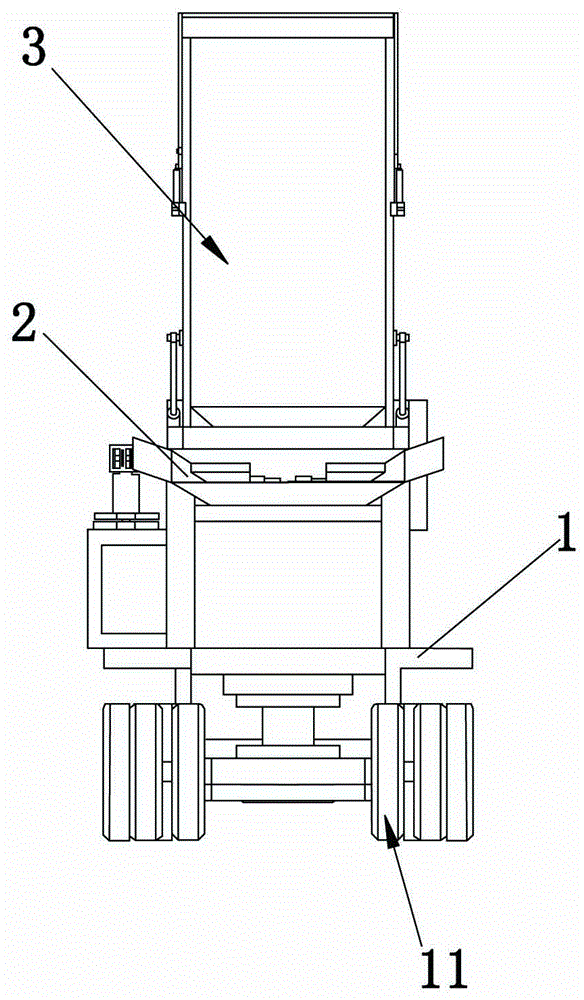

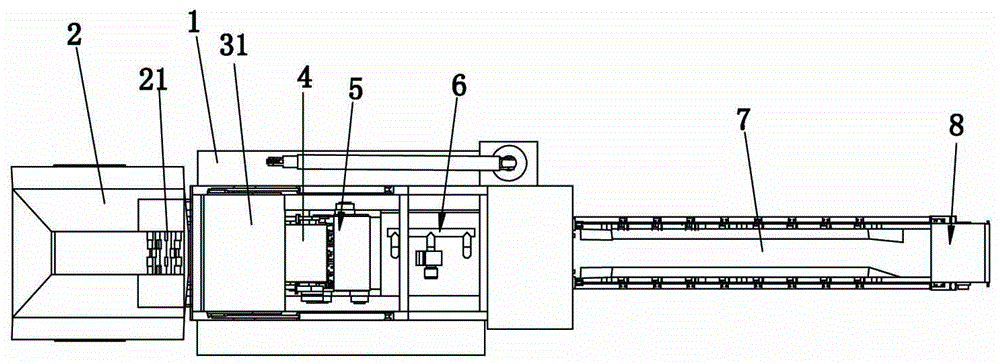

[0043] refer to figure 1 , figure 2 , image 3 as well as Figure 4 , an integrated humus treatment machine, including a frame 1, the frame 1 is provided with a feeding bin 2, a dosing device 3 and a crushing and stirring device 5 in the rear section. The frame 1 is provided with a feeding conveyor belt 4 communicated with a crushing and stirring device 5 below the feeding bin 2 and the feeding device 3 . The front section of the frame 1 is provided with a heating and stirring device 6 , a discharge conveyor belt 7 and a spraying and stirring device 8 connected in sequence, wherein the heating and stirring device 6 communicates with the crushing and stirring device 5 .

[0044] refer to figure 1 , figure 2 , image 3 as well as Figure 4 , the bottom of the frame 1 is provided with a running gear 11, and the running gear 11 can be a wheel or a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com