Meson continuous emitter for welding gun

A technology of repeater and meson, which is applied in the field of meson repeater for welding guns, can solve the problems of poor contact between welding meson and power supply electrode, and difficulty in placing welding meson, so as to avoid poor contact and reduce precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

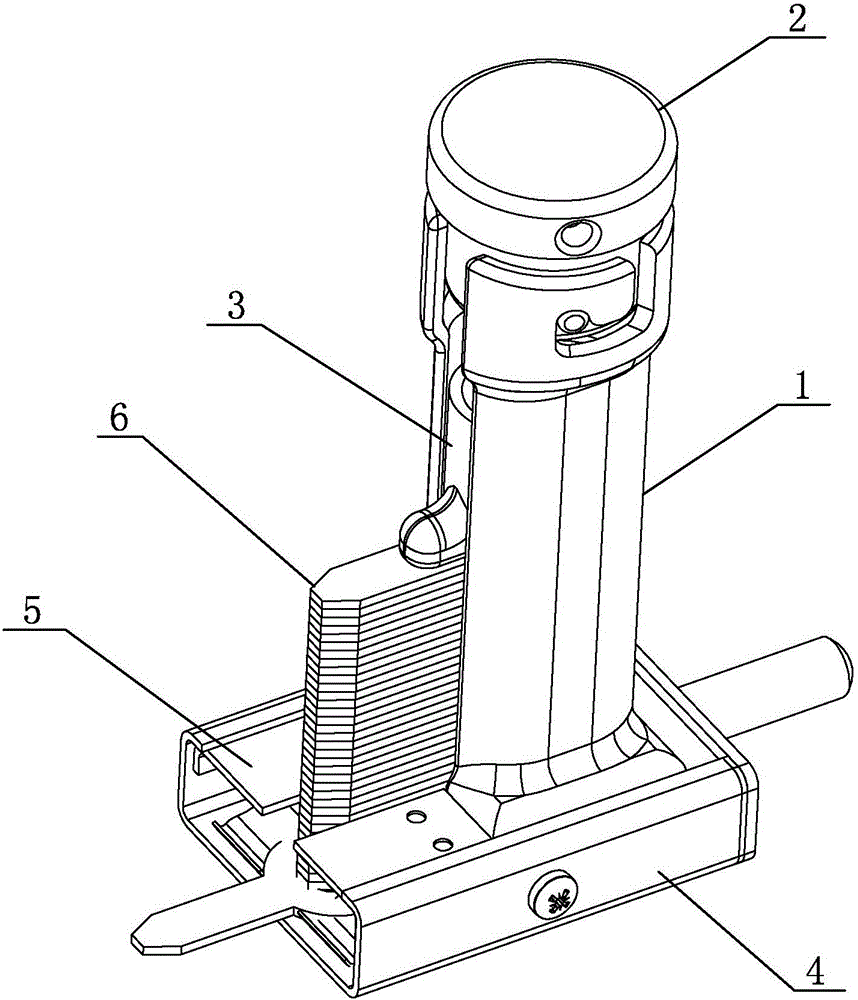

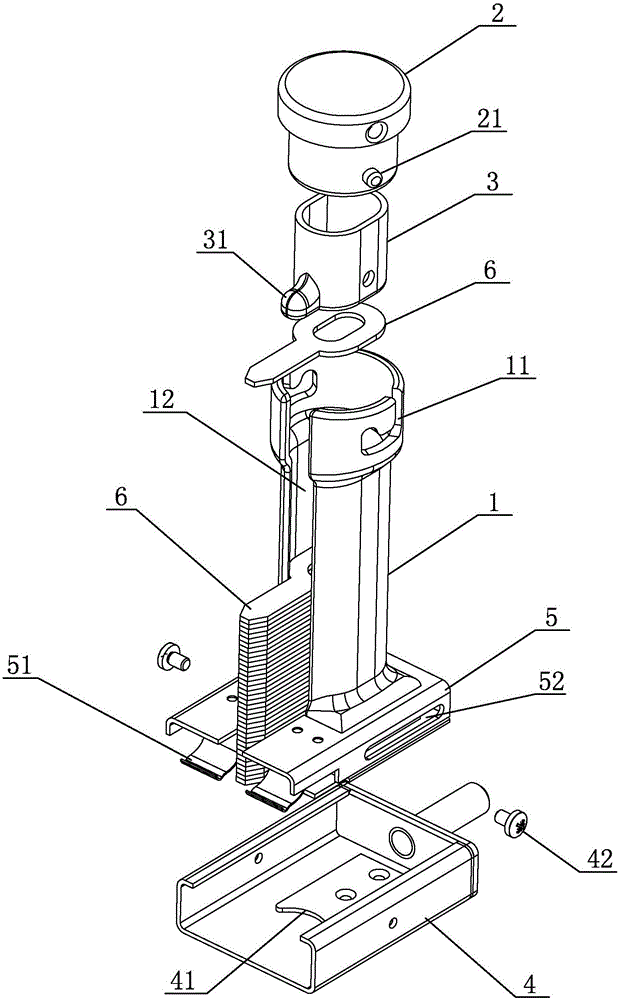

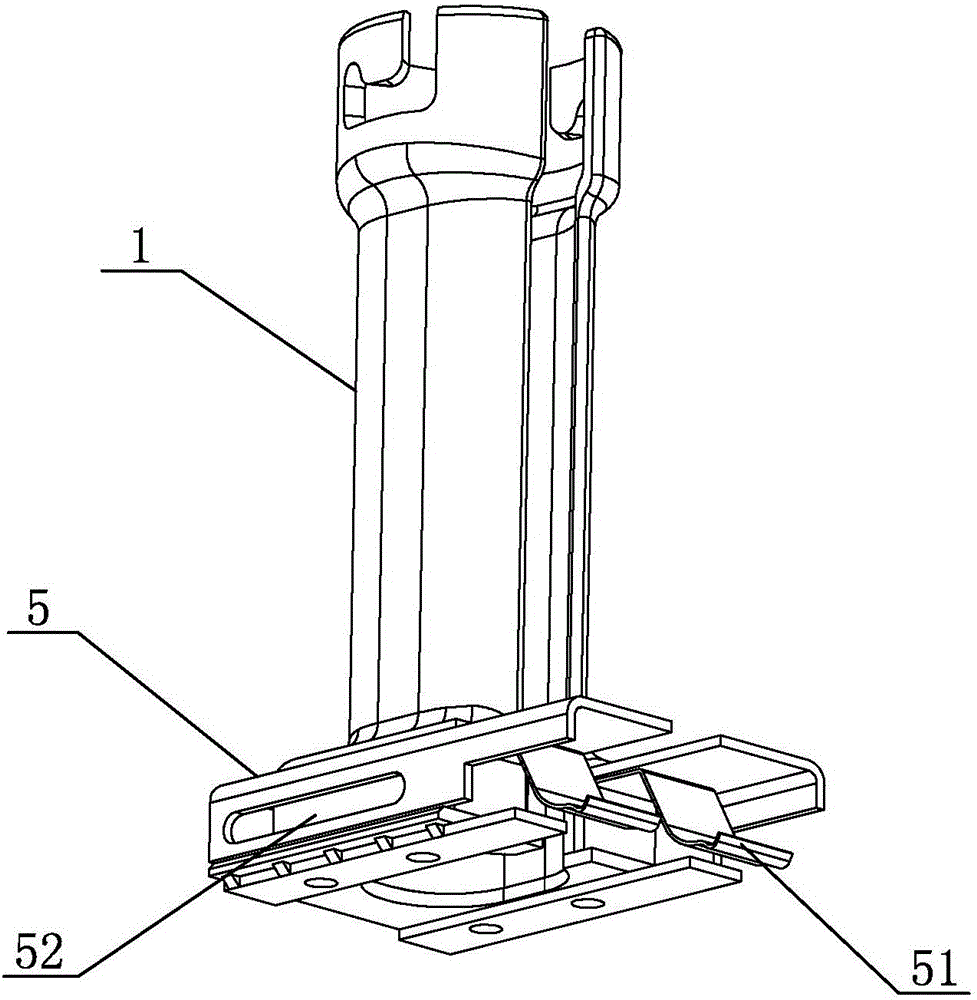

[0023] refer to Figure 1 to Figure 3 , a kind of meson repeater for a welding torch provided by the present invention includes an outer casing 4 , an inner casing 5 and a cylinder body 1 fixedly arranged on the inner casing 5 .

[0024] The outer casing 4 is connected to the power electrode, and the rear portion of the outer casing 4 is provided with a bump 41, so that the front end of the outer casing 4 forms a lower concave position for accommodating the welding meson 6, and the front end of the bump 41 is set to match the shape of the welding meson 6. arc. The inner housing 5 is arranged in the outer housing 4 and locked in position by bolts 42 . The side of the inner housing 5 is provided with slide grooves 52 corresponding to the bolts 42 , so that the inner housing 5 can slide back and forth relative to the outer housing 4 . The front end of the inner casing 5 is provided with an elastic clip 51 , and the bottom of the inner casing 5 corresponding to the cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com