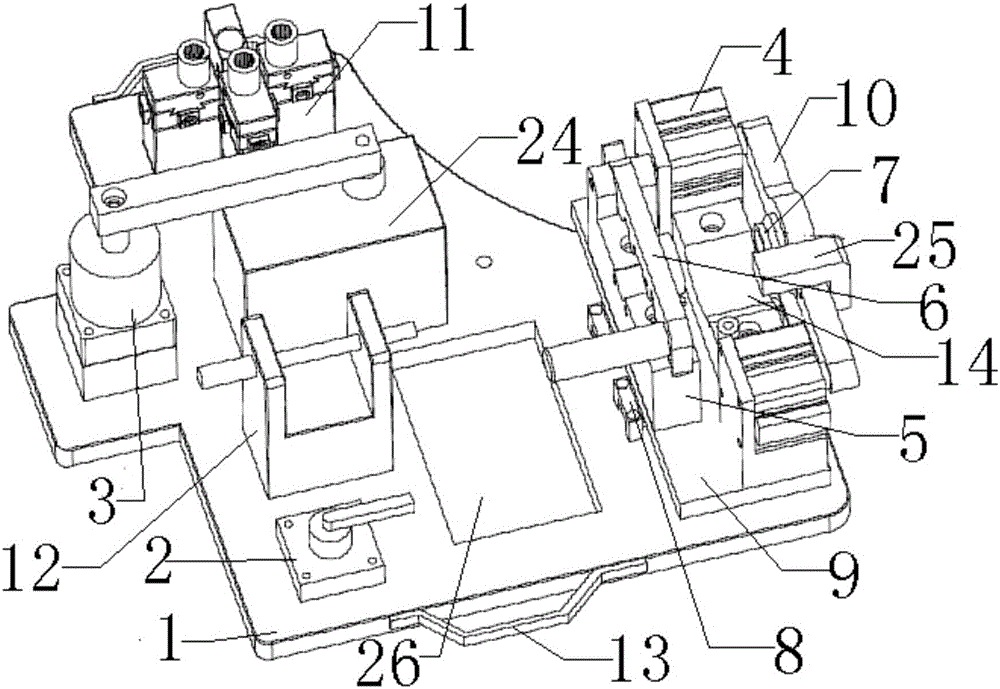

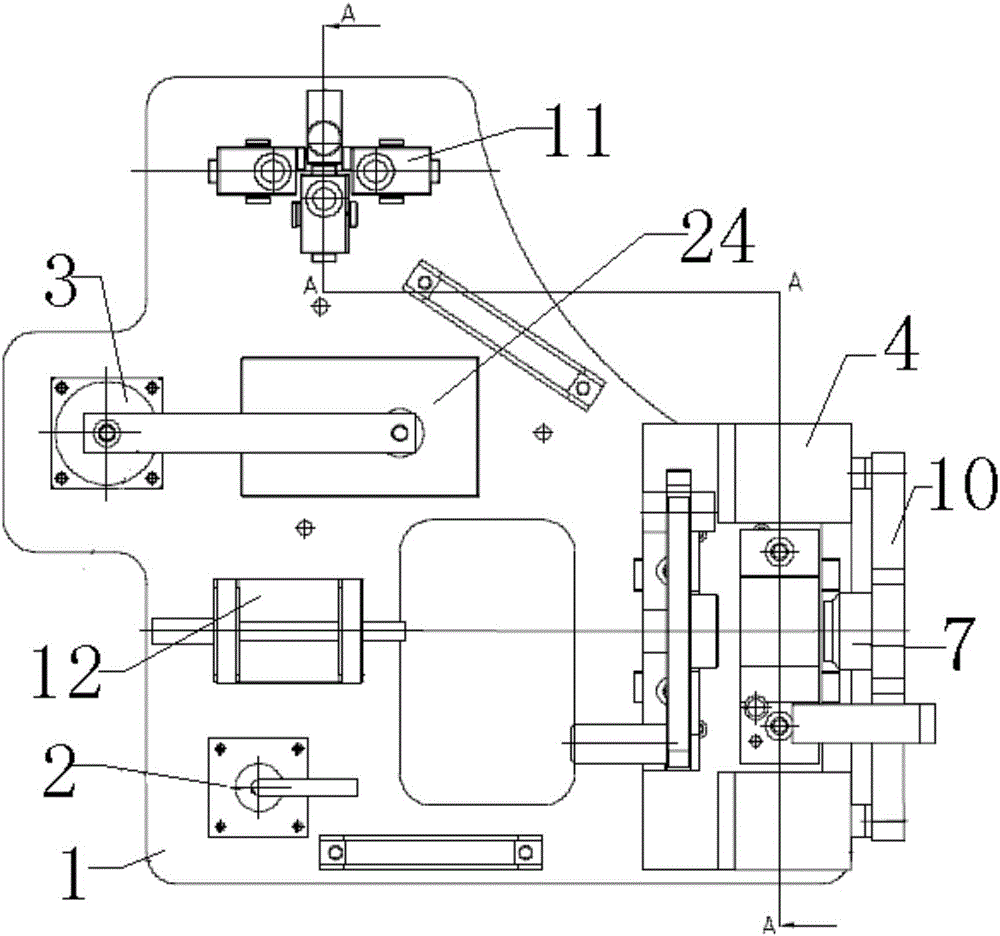

Anti-twisting assembly tool of vehicle front lower swing arm back hydraulic bushing

A technology of front lower swing arm and hydraulic bushing, applied in metal processing, manufacturing tools, vehicle parts, etc., can solve problems such as deflection, achieve the effects of reducing production costs, improving product qualification rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

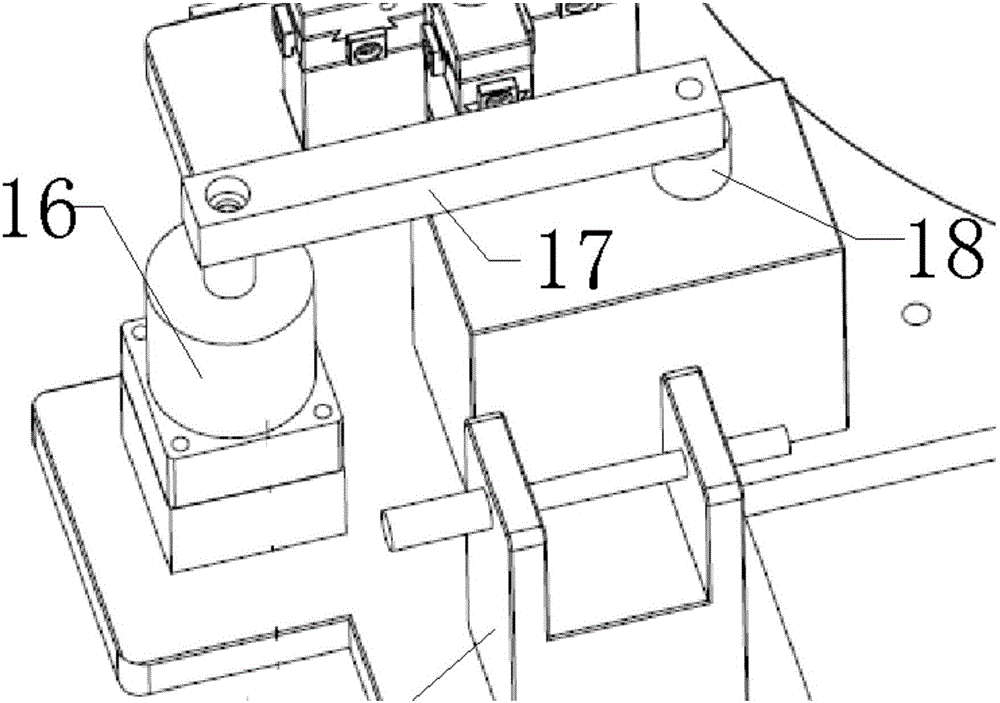

[0036] First start the torsion cylinder 16, lift the connecting arm 17 to a certain height, then rotate and adjust the position of the connecting arm 17, put the rear hydraulic bushing of the lower swing arm of the automobile on the support platform 24 in the middle of the product, and remove the rotating shaft 23 of the limit device 12, Insert the sleeve at one end of the bushing between the two side plates 22, fix it through the rotating shaft 23, align the threaded hole of the bushing with the threaded hole of the column 20 of the fixing seat 19, and fix it with several screws , then slide the movable plate 9 left and right, adjust it to a suitable position, turn the upper clamp 6, clamp one end of the bush through the cooperation of the upper clamp 6 and the lower clamp 5, and rotate the connecting arm 17 to align the pressure block 18 with the middle support of the product The bushing placed on the platform 24 controls the lowering of the connecting arm 17 until the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com