Jig for machining of columnar workpieces

A columnar workpiece and clamping technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high labor intensity, inability to complete automatically, and low degree of automation for operators, and achieve easy promotion, use, and design Reasonable and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

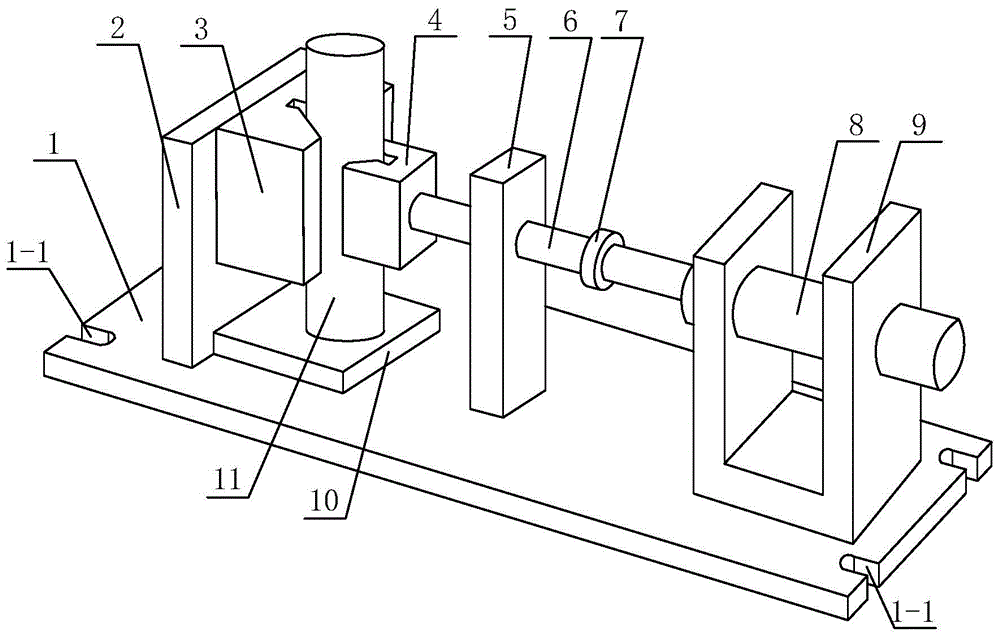

[0020] Such as figure 1 The shown tooling fixture for processing a columnar workpiece includes a rectangular bottom plate 1 that acts as a fixed support and has an open fixing groove 1-1 on the side wall, and a pad 10 for supporting and positioning the workpiece 11, and also includes a support for mutual cooperation. For clamping the V-shaped pad 3 and the compression head 4 of the workpiece 11 and the hydraulic cylinder 8 for driving the compression head 4; the upper side of one end of the rectangular bottom plate 1 is fixedly provided with a vertical plate 2, and the vertical plate 2 is fixedly installed with a V-shaped spacer 3, and a U-shaped bracket 9 is fixedly installed on the upper side of the other end of the rectangular bottom plate 1, and the upper side of the U-shaped bracket 9 is fixedly installed with the hydraulic cylinder 8, and the hydraulic cylinder 8 The piston rod is fixedly connected to one end of the push rod 6, the other end of the push rod 6 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com