Swinging type hand-held hole forming devices of combined type cutting machine

A cutting machine and swing-type technology, applied in the field of swing-type hand hole opening devices, can solve the problems of product quality impact, no automatic hand hole opening, and the cutting quality of the cutting machine is difficult to meet the requirements of precision block products. The effect of the special requirements of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

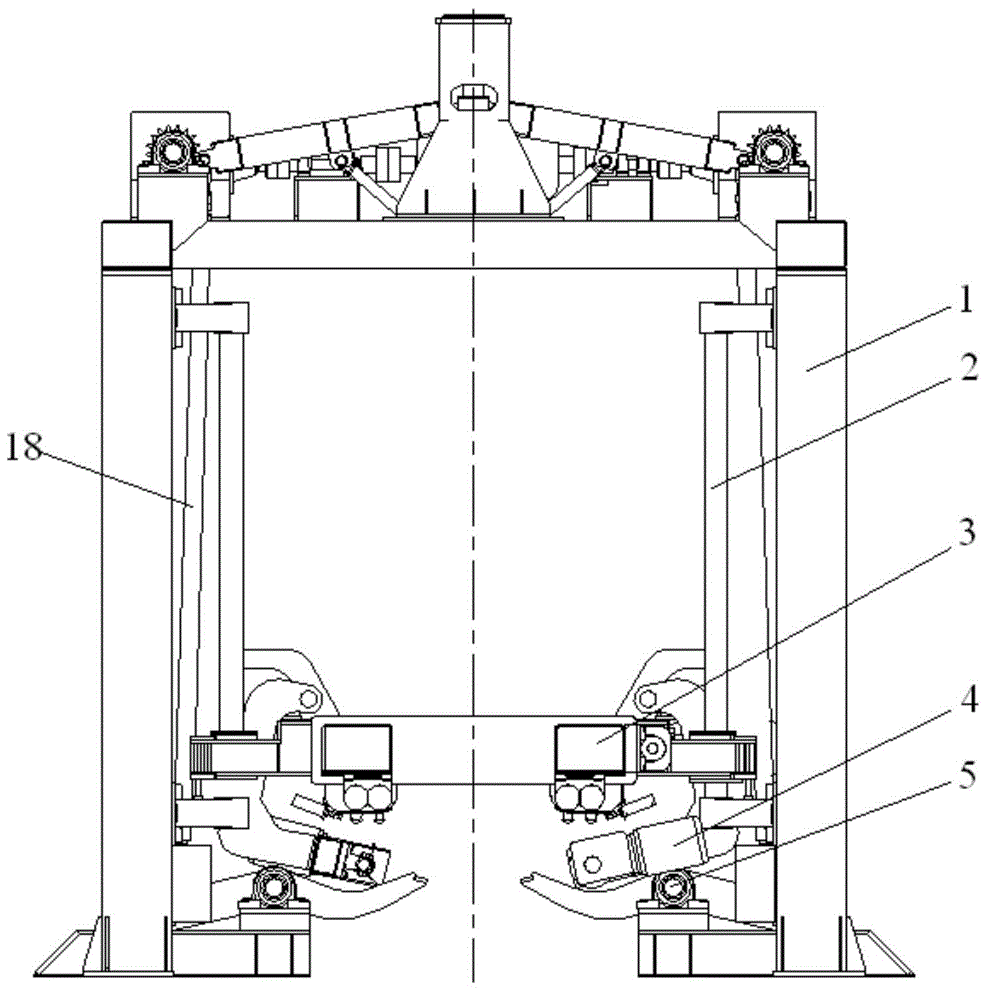

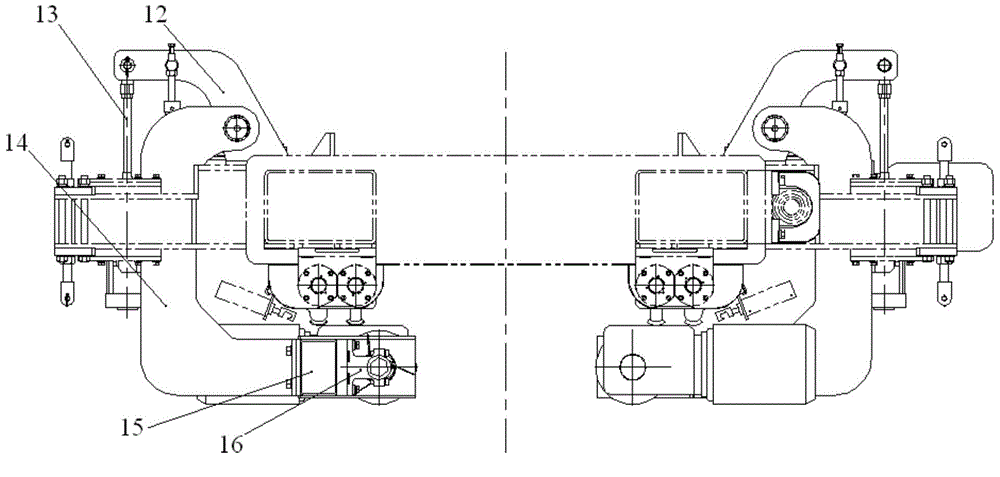

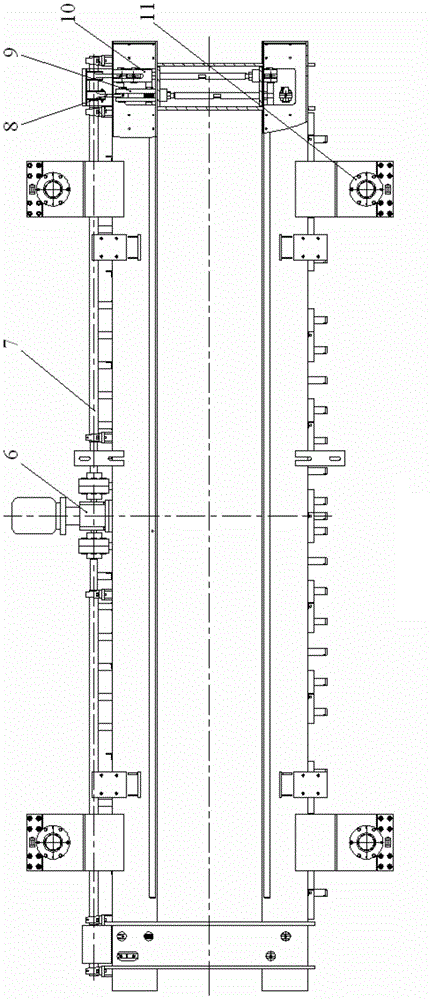

[0024] Such as Figure 1 to Figure 4 The structure of the present invention expressed is a new combined cutting machine, comprising a column lifting frame 1 (such as figure 1 shown), balanced cutting frame 3 (such as image 3 shown), the swing-type handle opening device 4 (such as figure 2 Shown),, mechanical synchronous jacking device 5 (such as Figure 4 shown).

[0025] In order to solve the problems existing in the prior art and overcome its defects, realize the purpose of the invention of improving the working stability of the equipment and improving the quality of block products, the technical scheme adopted by the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com