Effortless barrow for flour in bulk

A cart and flour technology, which is applied to carts, uniaxial carts, motor vehicles, etc., can solve the problems of unsuitable flour handling, heavy weight, and physical exertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

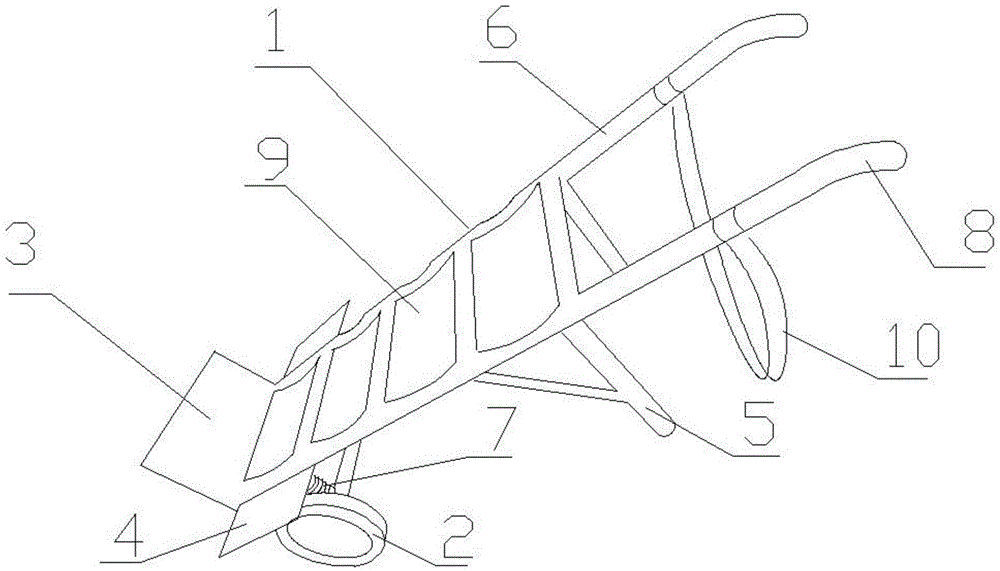

[0016] Such as figure 1 Shown, a kind of labor-saving flour bulk trolley comprises vehicle frame 1, wheel hub 2, shovel plate 3, stabilizing plate 4, support bar 5 and handle 6, and vehicle frame 1 is installed on the wheel hub 2, and the bottom of vehicle frame 1 and Buffering parts 7 are arranged between the hubs 2, handles 6 are fixed on both sides of the upper end of the vehicle frame 1, the distance between the handles 6 becomes larger from small to large, and one end of the handle 6 is bent into a downward pressure handrail 8, and the vehicle frame 1 is provided with multiple A transversely recessed arc surface baffle 9, the bottom of the baffle 9 is provided with a shovel 3, the support rod 5 is vertically fixed on the lower part of the handle 6, the handle 6 is also covered with a shoulder strap 10, the surface of the shovel 3 is a slope On the surface, the number of stable plates 4 is 2.

[0017] When the present invention is in use, the trolley is first placed verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com