Novel milk powder tin

A milk powder can, a new type of technology, applied in the direction of rigid container, clamping device, closing, etc., can solve the problems of being easy to lose, affecting the appearance, and difficult to cover, etc., to achieve reasonable structure setting, reasonable structure design, and improved anti-pressure performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

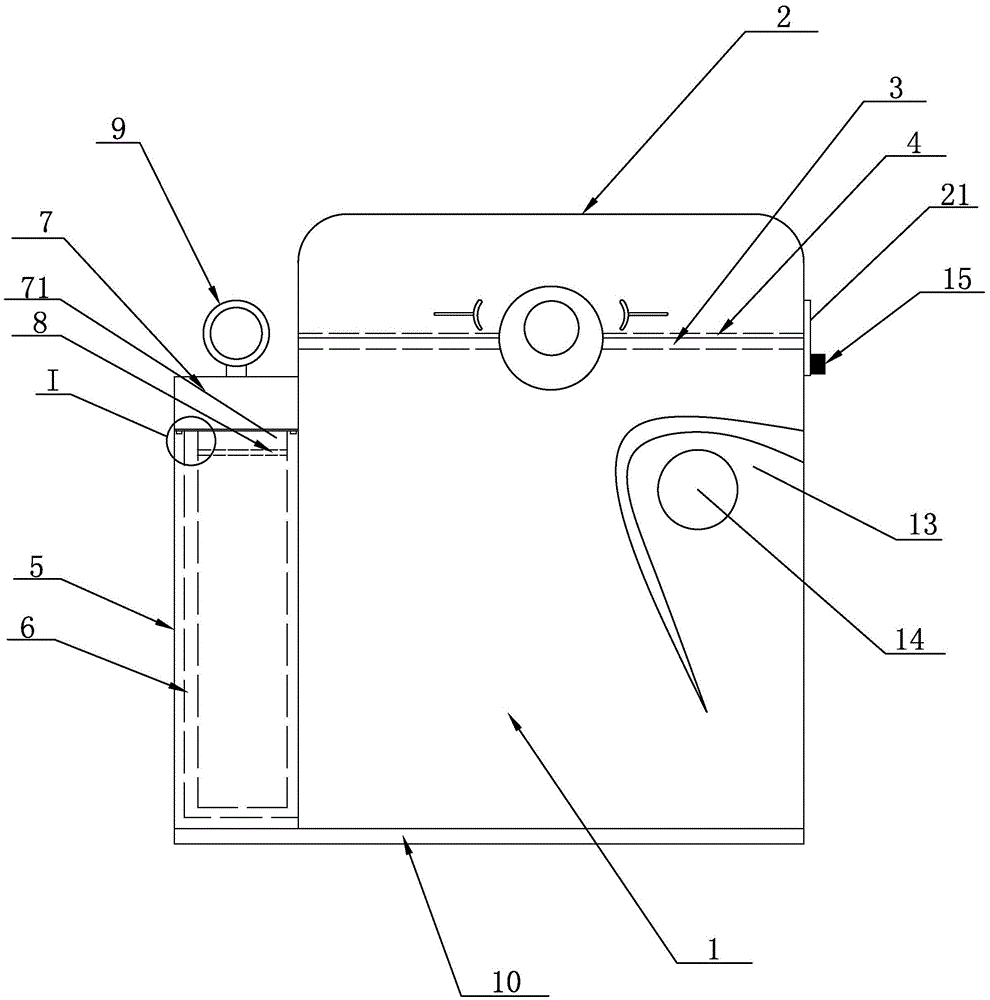

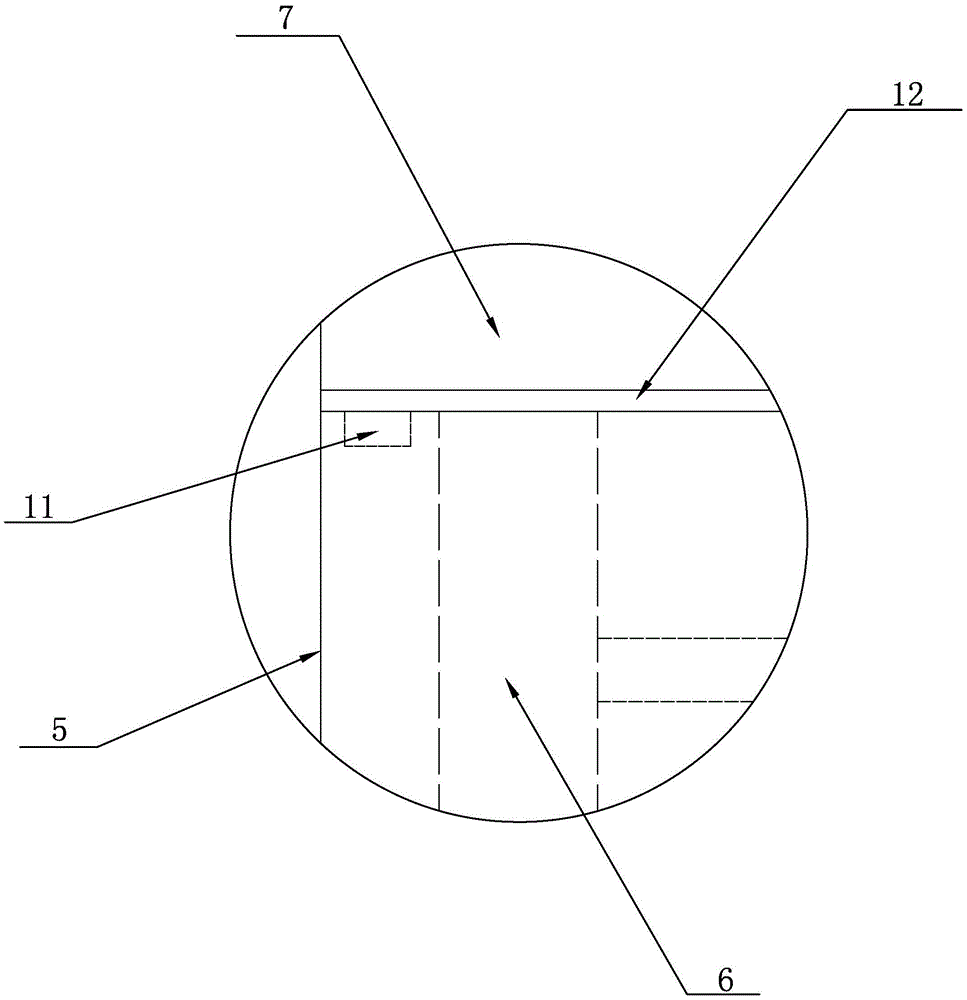

[0014] see figure 1 and figure 2 , a new type of milk powder tank disclosed by the present invention, comprising a tank body 1 and a flip cover 2 hinged at the upper opening of the tank body 1, a tank magnet 3 is embedded in the upper opening of the tank body 1, and the flip cover 2 A circle of flip iron sheet 4 is embedded on the lower end surface of the tank body 1; a spoon placement cylinder 5 is integrally provided on one side of the tank body 1, the opening of the spoon placement cylinder 5 is set upward, and the spoon placement cylinder 5 The first antibacterial layer 6 is fixedly arranged on the inner wall surface of the first antibacterial layer 6, and the thickness of the first antibacterial layer 6 is 1-3 mm; the upper end of the spoon placement cylinder 5 is inserted with a sealing cover 7, and the middle part of the lower end surface of the sealing cover 7 is A sealing bump 71 is integrally arranged, and a second antibacterial layer 8 is fixedly arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com