Compound and application thereof to home care

A compound and polymer technology, applied in the field of daily chemicals, can solve the problems of not being able to give full play to the optimal performance of the compound, and achieve the effect of improving foam washing performance, not easy to pour, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

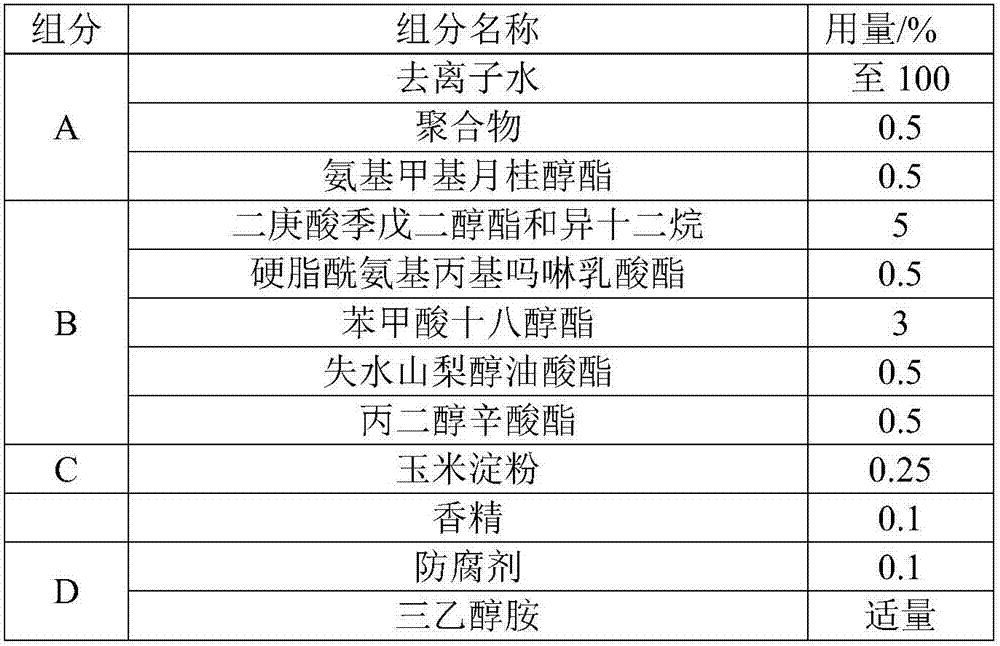

[0023] A kind of liquid detergent, its composition is following table 1.

[0024] Table 1 liquid detergent formula table

[0025]

[0026] The preparation method is as follows: add the polymer to deionized water, stir evenly, then add the remaining phase A, stir evenly, and heat up to 70-75°C; heat phase B to 70-75°C, and add it to phase A , mix evenly; cool to 45°C, add phase C, stir evenly; adjust the pH to 5.5-6.0.

[0027] In Example 1, the polymer is the compound of the present invention, wherein the weight ratio of A polymer and B polymer is 1:1.

[0028] Described A polymkeric substance is prepared by the following method:

[0029] 91g of acrylic acid, 9g of cetyl methacrylate, 0.083g of sorbitan fatty acid ester, 0.417g of sodium carbonate, and 0.2g of dodecyl mercaptan were added to 650g of organic solvents (300g of ethyl acetate, cyclohexane 350 g of alkanes), the temperature was raised to 55° C. under the protection of an inert gas, and 0.7 g of diisopropyl pe...

Embodiment 2

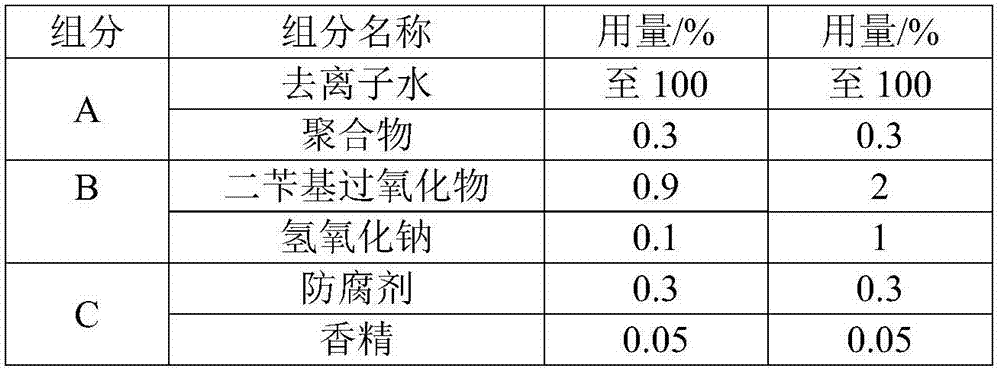

[0033] A kind of machine dishwashing detergent, its composition is as follows table 2

[0034] Formulation list of table 2 machine dishwashing detergent

[0035]

[0036] The specific preparation method is as follows: adding the polymer into deionized water, and stirring evenly; slowly adding phase B into phase A, mixing and stirring until completely dissolved; adding phase C, and stirring evenly.

[0037] In Example 2, the polymer is the compound of the present invention, wherein the weight ratio of A polymer and B polymer is 2:1. The preparation method of described A polymer and B polymer is the same as embodiment 1.

Embodiment 3

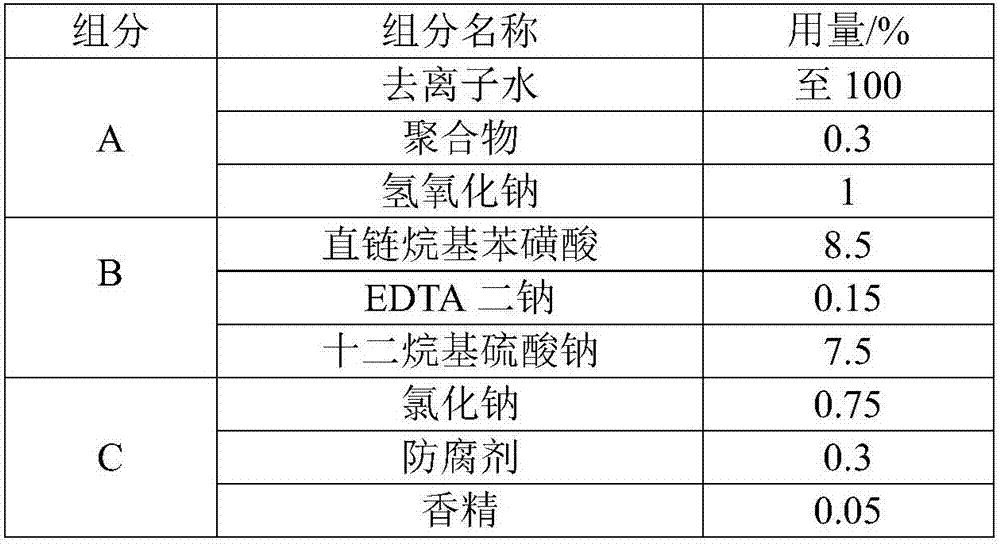

[0039] A kind of hand dishwashing detergent, its composition is as follows table 3

[0040] Formulation table of table 3 hand dishwashing detergent

[0041]

[0042] The preparation method specifically includes: adding the polymer into deionized water, dispersing evenly, adding alkali to neutralize; slowly adding phase B into phase A, mixing and stirring evenly; adding phase C, stirring evenly.

[0043] In Example 3, the polymer is the compound of the present invention, wherein the weight ratio of A polymer and B polymer is 1:2.

[0044] Described A polymkeric substance is prepared by the following method:

[0045] 94g acrylic acid, 6g octadecyl methacrylate, 0.75g sorbitan fatty acid ester, 0.25g sodium bicarbonate, 0.3g tetradecyl mercaptan, join 600g organic solvent (ethyl acetate 400g, ring Hexane (200 g) was heated to 50° C. under the protection of an inert gas, and 0.5 g of initiator di-n-propyl peroxydicarbonate was added dropwise for 4 hours. After the dropwise a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com