Semi-automatic lock for container highway transportation

A technology for road transportation and containers, which is applied in the field of semi-automatic locks for container road transportation, which can solve the problems of high risk, high labor intensity of workers, and low efficiency of manual lock operation, so as to avoid safety accidents, reduce labor intensity of workers, and save operation The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

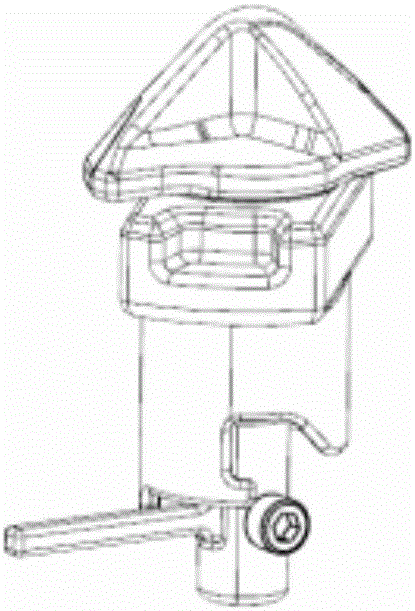

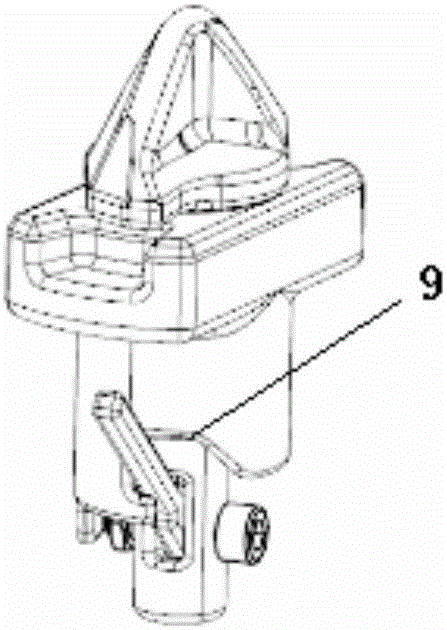

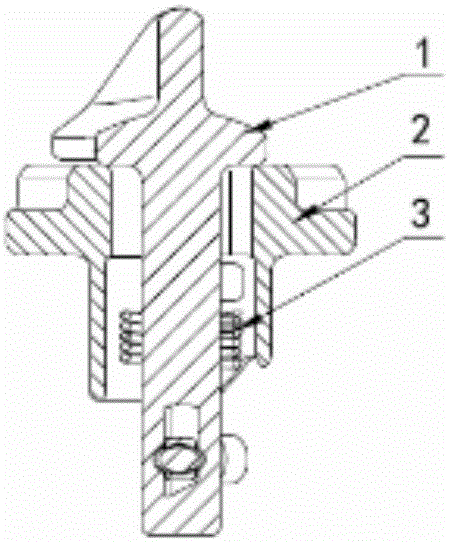

[0024] Such as Figure 1~4 As shown, a semi-automatic lock for container road transport includes a lock shaft 1, a housing 2, a spring 3 and a handle 4, wherein the upper end of the lock shaft 1 is a lock head 5, and the lower end is a rotating shaft 6, and the rotating shaft 6 is provided with a spring clip 7 in the middle, and a handle 4 is installed at the lower end of the rotating shaft 6, and the handle 4 can rotate up and down relative to the rotating shaft 6. The lock shaft 1 is installed on the housing 2, and the housing 2 There is a card slot 9 at the position corresponding to the handle 4 at the lower end, and a limit protrusion 8 is provided on one side of the card slot 9 for limiting the handle 4. The lower end of the spring clamp 7 and the rotating shaft 6 are equipped with The spring 3, the two ends of the spring 3 are respectively connected with the rotating shaft 6 and the housing 2, and is used for resetting the locking head 5 after rotating.

[0025] The low...

Embodiment 2

[0034] The operation steps when loading the container are:

[0035] 1, the present invention is installed on the car body, as Figure 8 shown;

[0036] 2. Observe each lock to make each lock in a locked state, such as figure 1 shown;

[0037] 3. Lift the container to the top of the car body, and align the corner fitting holes of the container with the lock head, such as Figure 9 shown;

[0038] 4. Drop the container, reset the lock head after rotating, and complete the loading. At this time, the container and the car body are locked together, such as Figure 10 and Figure 11 shown.

Embodiment 3

[0040] The operation steps when unloading the container are as follows:

[0041] 1. Pull the handle, put the handle in the groove of the shell, at this time the lock is opened, as Figure 12 and Figure 13 shown;

[0042] 2. Lift the container and lift it away to complete the unloading, such as Figure 14 shown;

[0043] 3. Open the handle to reset the lock, such as Figure 15 shown in preparation for the next load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com