Conveying device and method for conveying strip-shaped workpieces

A strip-shaped workpiece and conveying device technology, which is applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of low degree of automation, large number of workers, damaged workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

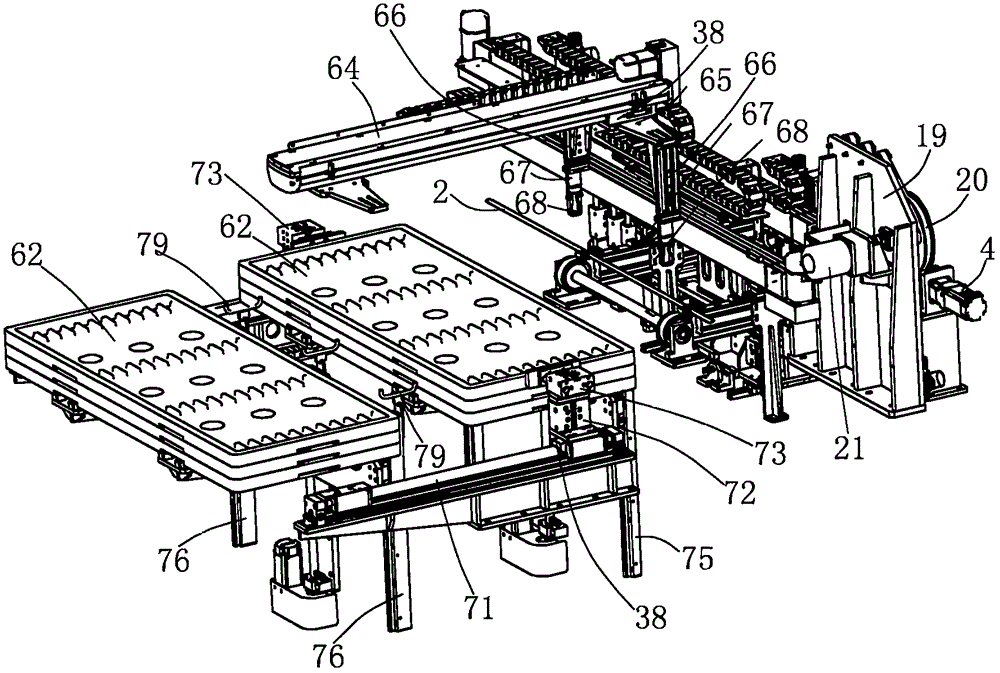

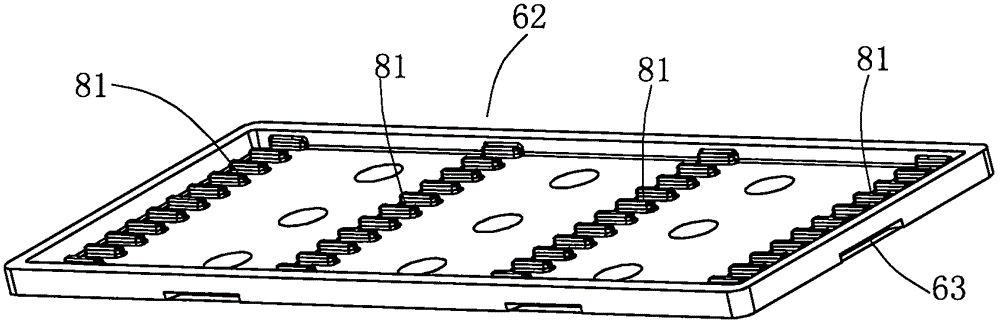

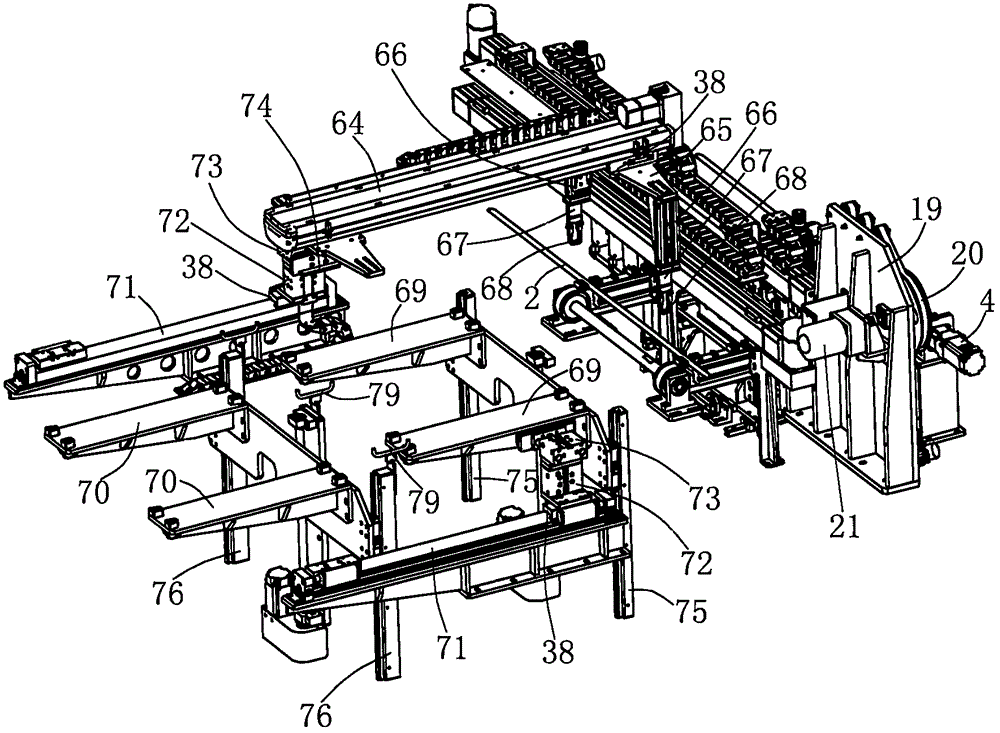

[0015] The present invention is used for the conveying device of conveying strip workpiece 2, as figure 1 , image 3 As shown, including a frame, a plurality of workpiece turnover discs 62 are configured, and the workpiece turnover discs 62 are suitable for multiple overlapping placements. Each workpiece turnover disc is suitable for storing a plurality of strip-shaped workpieces 2. The left and right sides of each workpiece turnover disc 62 are arranged Concave 63, the conveying device includes an electric cylinder 64 arranged longitudinally above the frame according to the conveying stroke, the moving block 38 of the electric cylinder 64 is fixedly connected to the moving plate 65, and the left and right sides of the moving plate 65 are respectively connected to the fifteenth cylinder 66 , the piston rods of the 2 fifteenth cylinders 66 are fixedly connected to the sixteenth cylinder 67 respectively, and a pair of rotating rods of the sixteenth cylinder 67 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com