Jacking platform box girder support structure for super high-rise buildings and its construction method

A technology for lifting platforms and supporting structures, which is applied to building construction, on-site preparation of building components, construction, etc., and can solve problems affecting the safety of the lifting platform and inconsistent design elevations of corbels 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

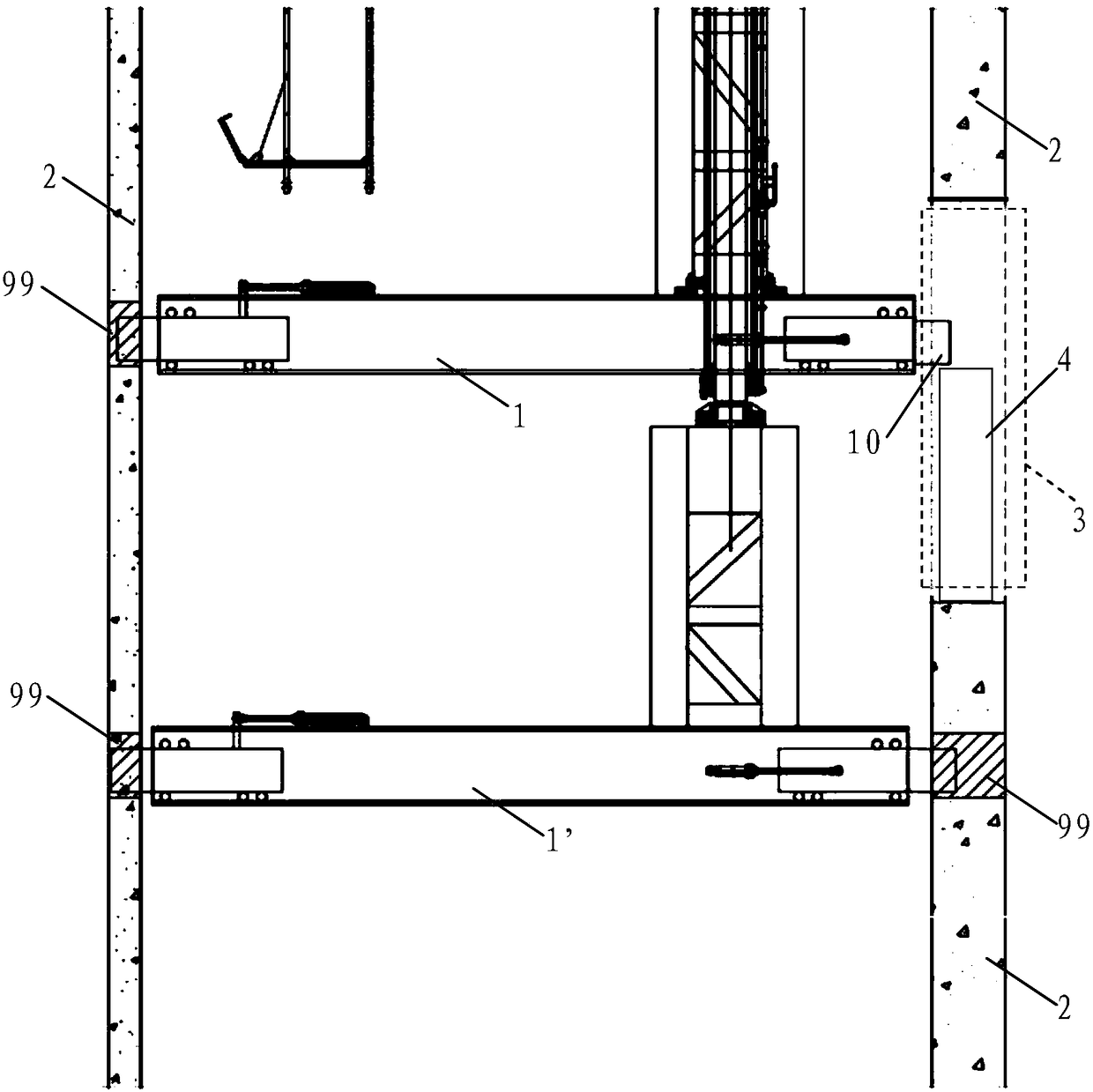

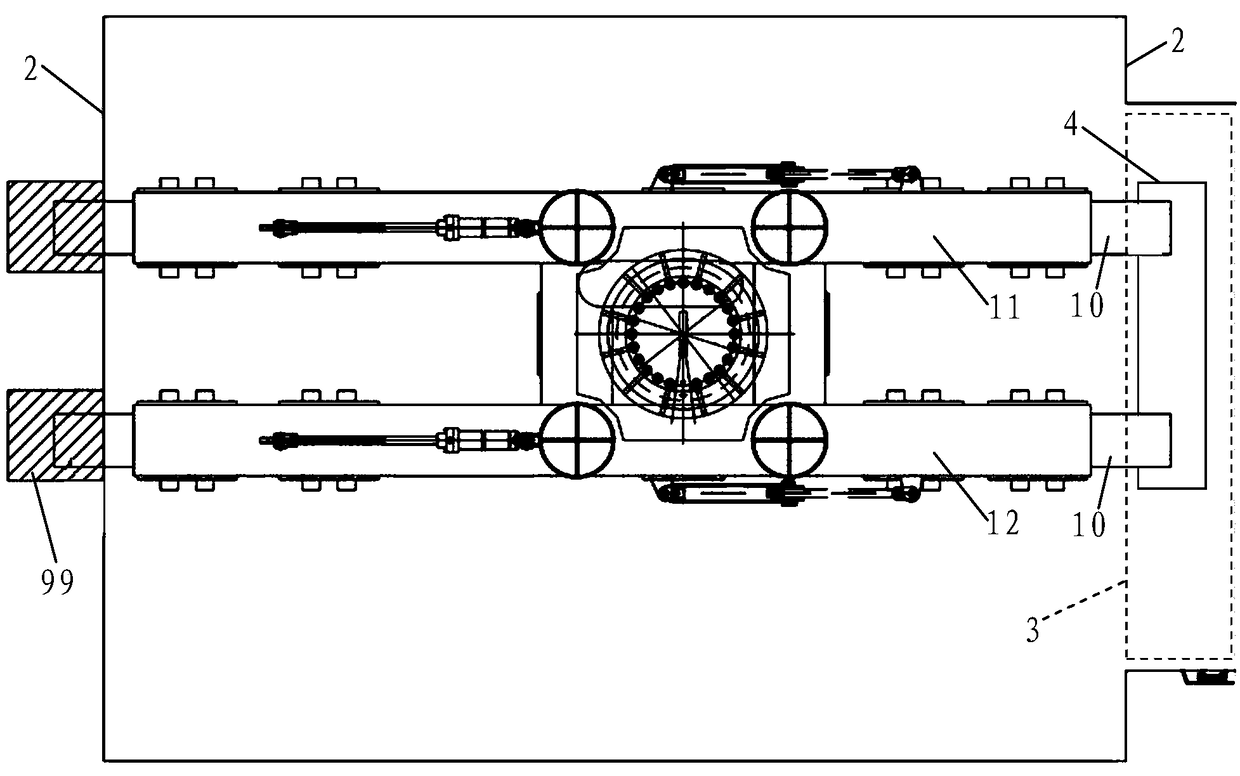

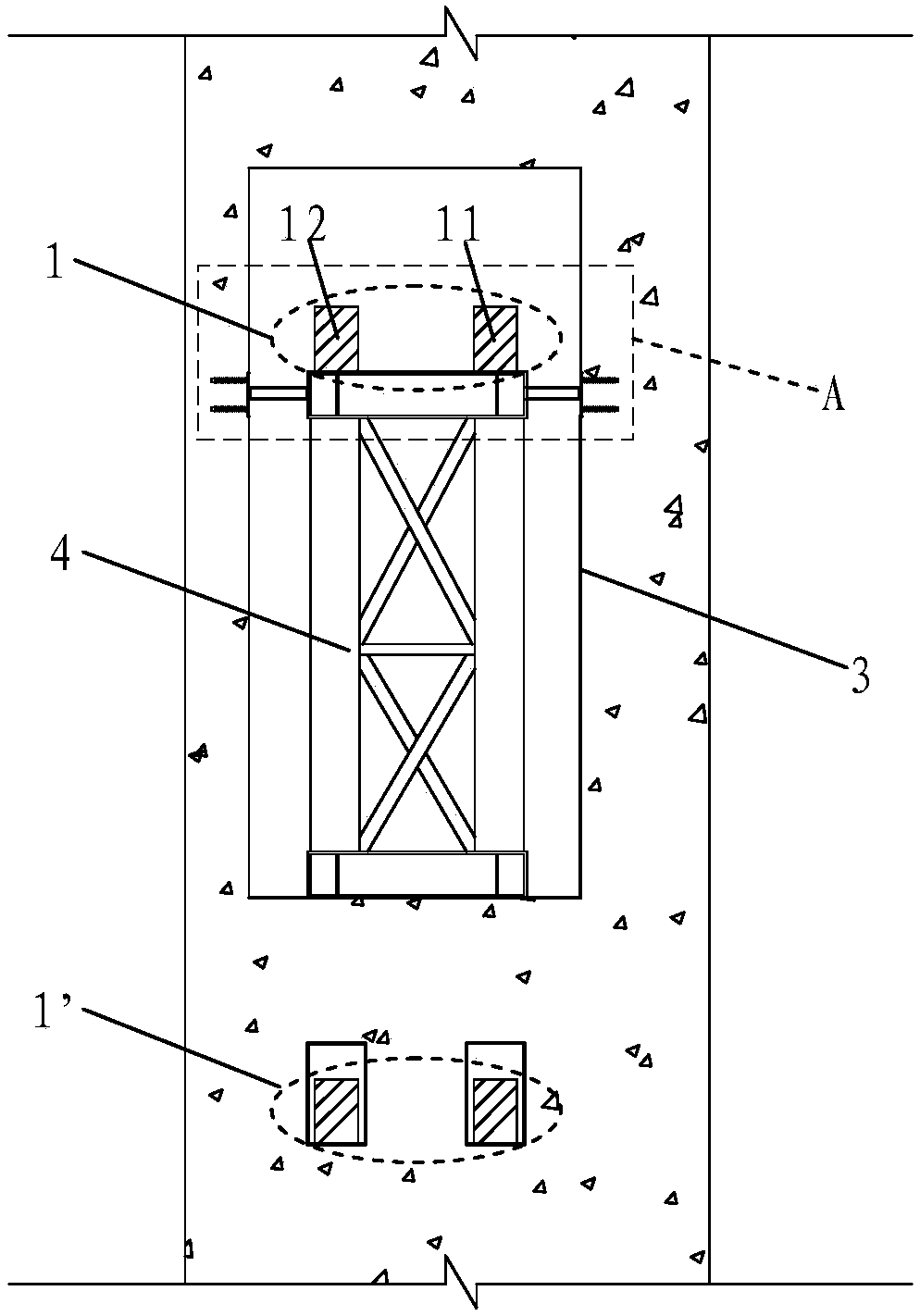

[0034] combine Figure 1 to Figure 3 As shown, the present invention provides a jacking platform box girder support structure and construction method thereof for super high-rise buildings, wherein, the upper group of jacking platform box girders are respectively supported through the reserved openings 99 on the shear wall 2 1 and the lower group of jacking platform box girder 1', a shear wall opening 3 is formed on the right shear wall 2, and the right end of the upper group of jacking platform box girder 1 is just within the height range of the shear wall opening 3 Furthermore, the corbel 10 at the right end of the jacking platform box girder 1 of the group is suspended in the air, and the two ends of the jacking platform box girder 1' of the lower group are respectively supported in the corresponding reserved openings 99 on the shear wall, such as image 3 , in order to solve the problem of the suspension of the box girder corbels, the application is provided with a temporar...

Embodiment 2

[0038] On the basis of Embodiment 1, there are two sets of jacking platform box girders within the height range of the shear wall opening 3, and the upper set of jacking platform box girders 1 includes the first box girder 11 with one end suspended in the air and the The second box girder 12 and the lower group jacking platform box girder 1 ′ include a third box girder 13 and a fourth box girder 14 supported on the bottom surface of the opening 3 of the shear wall. In order to solve the box girder support in this case, the application selects a lattice column support 4a with a wide top and a narrow bottom, and supports the upper end of the lattice column support 4a on the first box beam 11 and the second box beam 11. Below the corbel 10 of the box girder 12 , the lower end base of the lattice column support 4 a is supported on the bottom surface of the shear wall opening 3 between the third box girder 13 and the fourth box girder 14 . The other structures are basically the sam...

Embodiment 3

[0040] Such as Figure 6 As shown, the application also discloses another suspended state of the box girder. In the figure, only the box girder 1 of the upper group jacking platform is within the height range of the shear wall opening 3. This suspended state and figure 2 In contrast, the difference of this kind of suspended state is that the combination of Figure 7 As shown, the shear wall opening 3 is inverted L-shaped and has a vertical opening section 30 and a horizontal opening section 32, the horizontal opening section 32 has a supporting shear wall 20, and the right end of the first box girder 11 The corbel 10 is suspended in the horizontal opening section 32 , and the right end corbel 10 of the second box girder 12 is located at the intersection of the vertical opening section 30 and the horizontal opening section 32 to be suspended in the air. In order to solve the box girder support in this case, this application proposes another temporary support frame structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com