A post-installation method for exterior windows of a prefabricated shear wall system

A shear wall, prefabricated technology, applied in windows/doors, building components, thermal insulation, etc., can solve the problems of difficult protection of finished products, low adaptability to deformation, etc., and achieve simple and fast installation and construction, strong integrity, and airtightness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

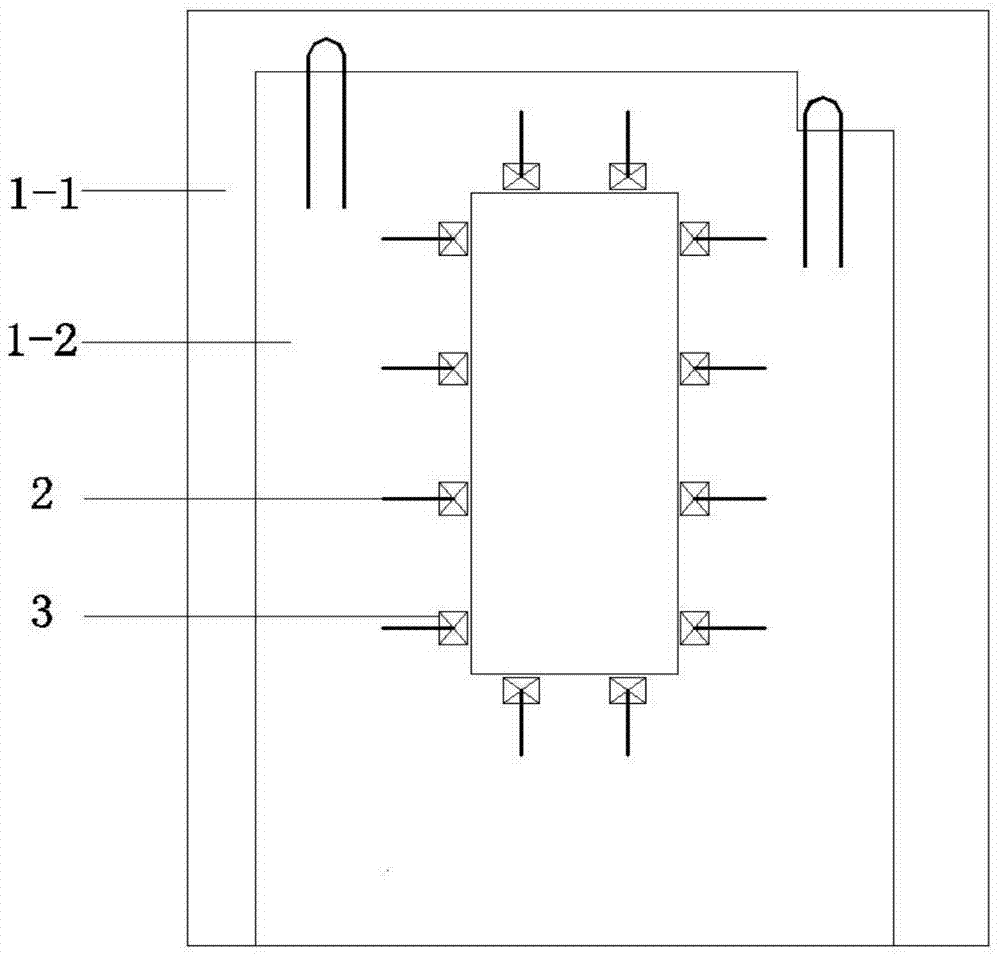

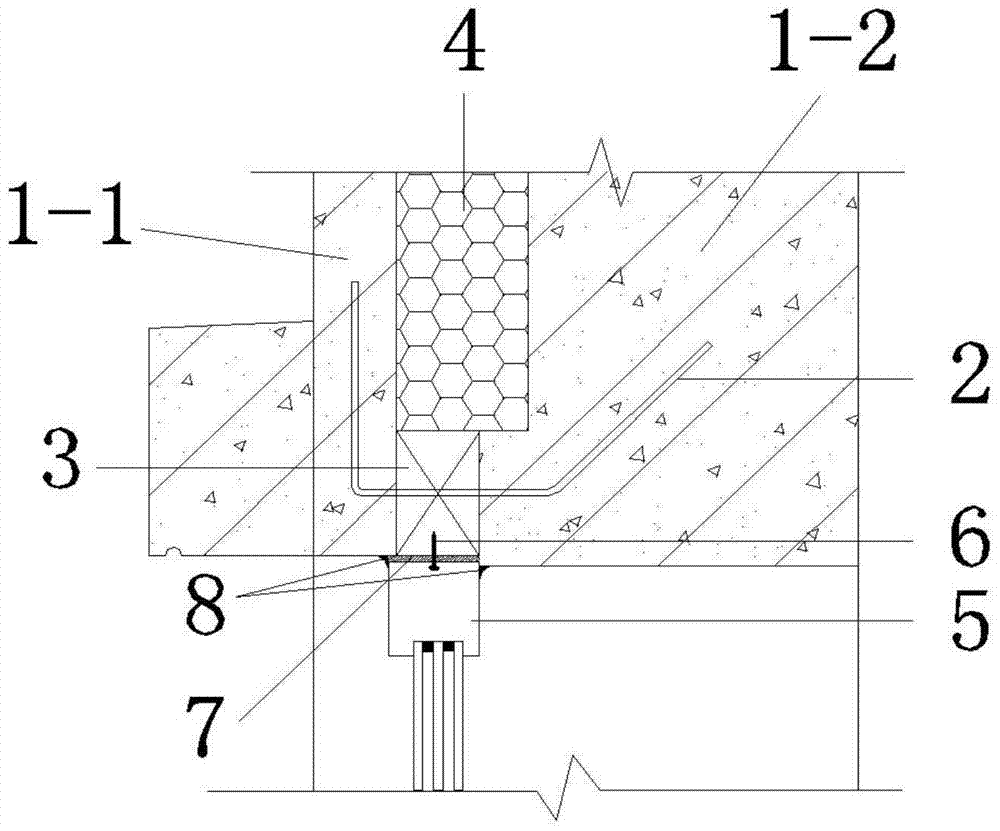

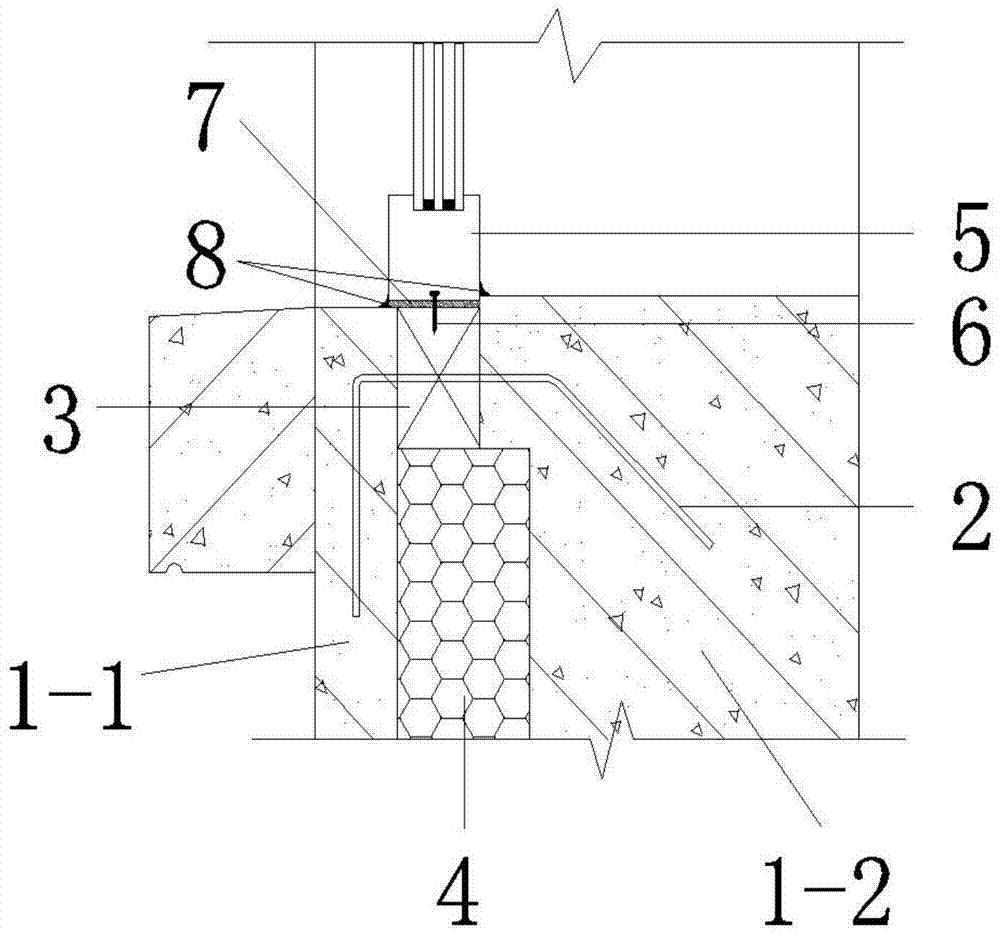

[0029] (1) Bind the outer leaf plate 1-1 steel bars of the outdoor part of the exterior wall panel around the reserved window position and bind a plurality of connecting steel bars 2 as connectors for the window brick 3 to be installed, and the multiple connecting steel bars 2. The part of the outer leaf plate 1-1 is perpendicular to the window wall at the corresponding position, and the plurality of connecting steel bars 2 are arranged perpendicular to each other on the part of the outer leaf plate 1-1 and the part of the window wooden brick 3 to be installed;

[0030] (2) Pouring concrete at 1-1 of the outer blade;

[0031] (3) Install the sandwich insulation board 4 between the outer blade 1-1 and the inner blade 1-2 of the indoor part of the outer wall panel to be constructed and reserve a space for installing window wooden bricks near the window side;

[0032] (4) a plurality of window wooden bricks 3 are installed at intervals in the space formed by the outer blade 1-1 i...

Embodiment 2

[0038] (1) Bind the outer leaf plate 1-1 steel bars of the outdoor part of the exterior wall panel around the reserved window position and bind a plurality of connecting steel bars 2 as connectors for the window brick 3 to be installed, and the multiple connecting steel bars 2. The part of the outer leaf plate 1-1 is perpendicular to the window wall at the corresponding position, and the plurality of connecting steel bars 2 are arranged perpendicular to each other on the part of the outer leaf plate 1-1 and the part of the window wooden brick 3 to be installed;

[0039] (2) Pouring concrete at 1-1 of the outer blade;

[0040] (3) Install the sandwich insulation board 4 between the outer blade 1-1 and the inner blade 1-2 of the indoor part of the outer wall panel to be constructed and reserve a space for installing window wooden bricks near the window side;

[0041] (4) a plurality of window wooden bricks 3 are installed at intervals in the space formed by the outer blade 1-1 i...

Embodiment 3

[0047](1) Bind the outer leaf plate 1-1 steel bars of the outdoor part of the exterior wall panel around the reserved window position and bind a plurality of connecting steel bars 2 as connectors for the window brick 3 to be installed, and the multiple connecting steel bars 2. The part of the outer leaf plate 1-1 is perpendicular to the window wall at the corresponding position, and the plurality of connecting steel bars 2 are arranged perpendicular to each other on the part of the outer leaf plate 1-1 and the part of the window wooden brick 3 to be installed;

[0048] (2) Pouring concrete at 1-1 of the outer blade;

[0049] (3) Install the sandwich insulation board 4 between the outer blade 1-1 and the inner blade 1-2 of the indoor part of the outer wall panel to be constructed and reserve a space for installing window wooden bricks near the window side;

[0050] (4) a plurality of window wooden bricks 3 are installed at intervals in the space formed by the outer blade 1-1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com