A time-controlled snap-press type multi-purpose fully enclosed safety valve

A multi-purpose, fully enclosed technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of poor sealing, inconvenient operation, easy to occur safety accidents, etc., to improve practical performance, good sealing, The effect of design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

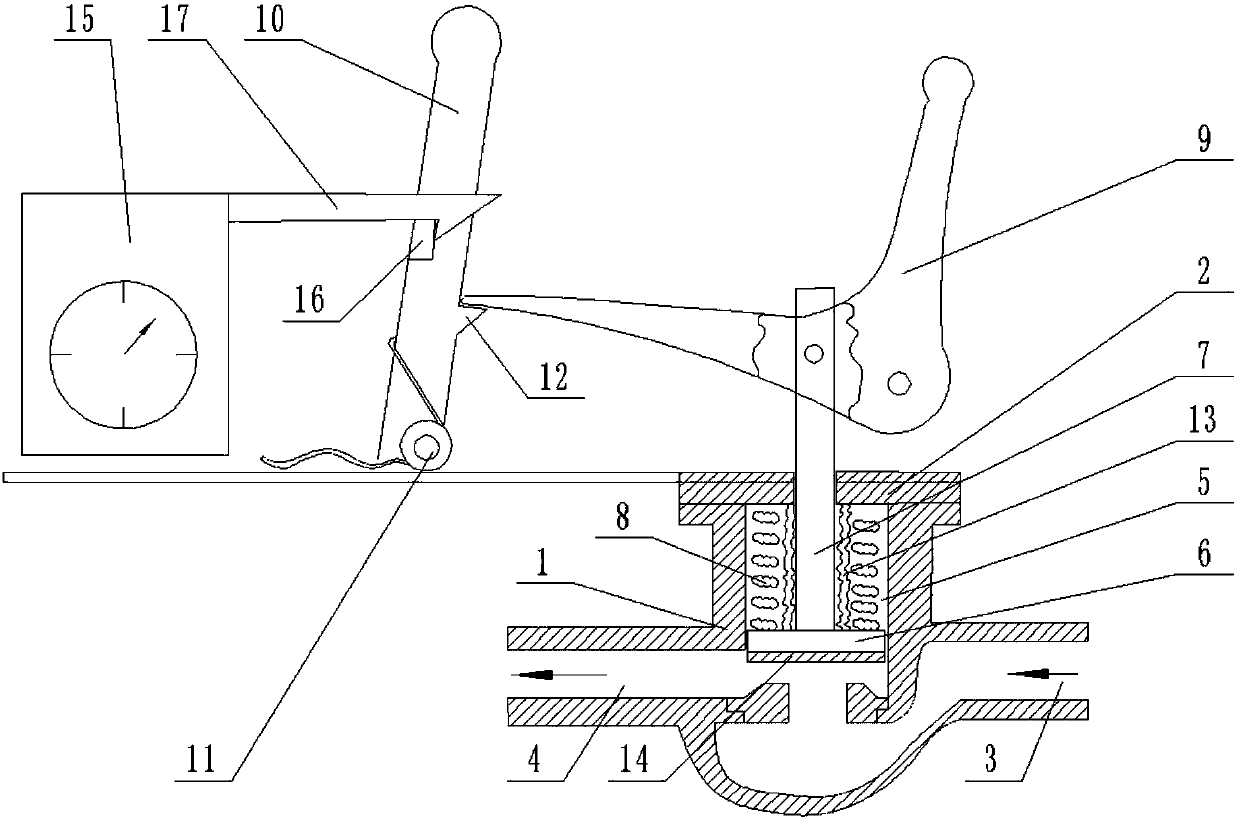

[0024] Such as figure 1 As shown, a time-controlled snap-press type multi-purpose fully enclosed safety valve is provided, including a valve body 1 and a valve cover 2; the valve body 1 is provided with an inlet pipe 3 and an outlet pipe 4; the inlet pipe 3 and the outlet pipe 4 A valve chamber 5 is provided above the air hole at the connection; a snap switch is provided in the valve chamber 5; the snap switch is mainly composed of a piston 6, a piston rod 7, a compression spring 8, an eccentric wheel lever 9 and The fixed rod 10 is formed; the eccentric wheel lever 9 is installed above the valve cover 2; one end of the eccentric wheel lever 9 is a limit end, the limit end extends to the fixed rod 10, and the other end is a switch operation end; The bottom of the fixed rod 10 is fixedly installed by a torsion spring 11, and the fixed rod 10 is provided with a platform 12 for fixing the limit end of the eccentric wheel lever 9; the upper part of the piston rod 7 passes through ...

Embodiment 2

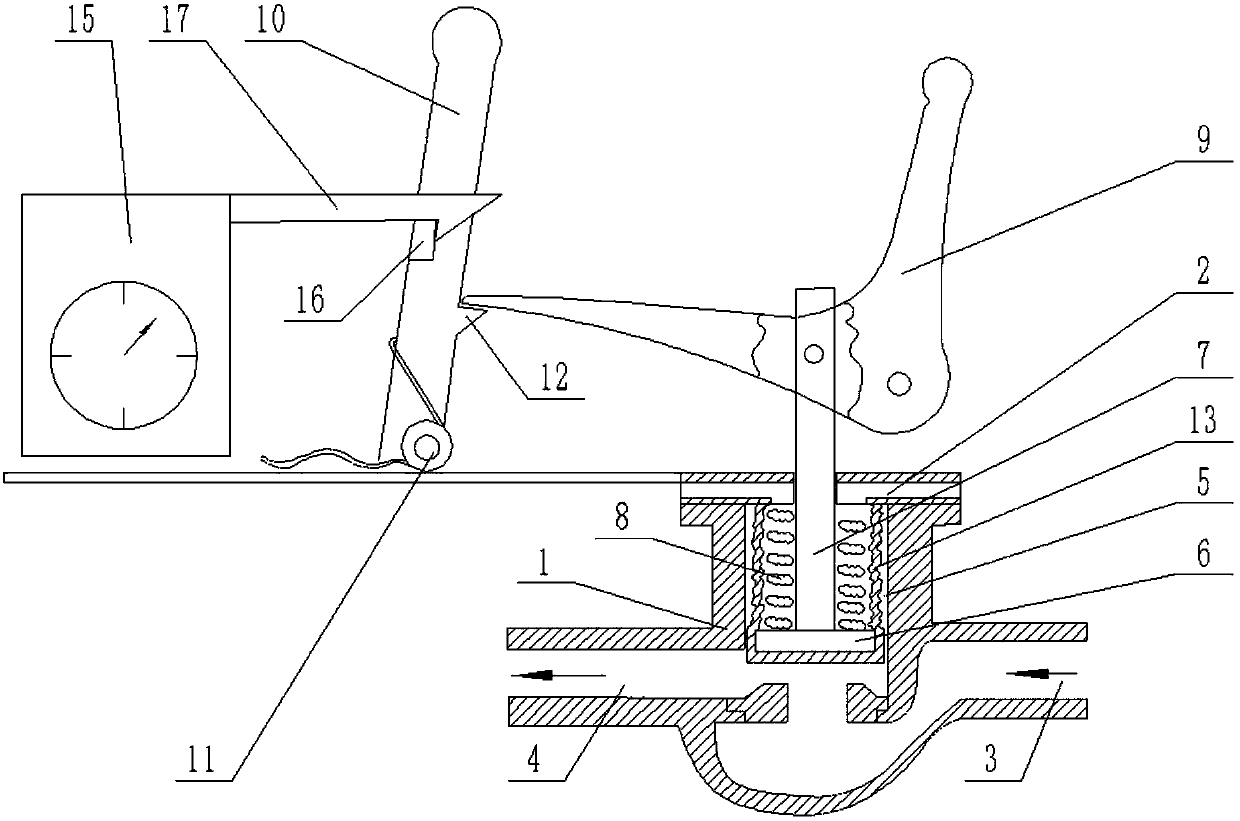

[0028] Such as figure 2 As shown, a time-controlled snap-press type multi-purpose fully enclosed safety valve is provided, including a valve body 1 and a valve cover 2; the valve body 1 is provided with an inlet pipe 3 and an outlet pipe 4; the inlet pipe 3 and the outlet pipe 4 A valve chamber 5 is provided above the air hole at the connection; a snap switch is provided in the valve chamber 5; the snap switch is mainly composed of a piston 6, a piston rod 7, a compression spring 8, an eccentric wheel lever 9 and The fixed rod 10 is formed; the eccentric wheel lever 9 is installed above the valve cover 2; one end of the eccentric wheel lever 9 is a limit end, the limit end extends to the fixed rod 10, and the other end is a switch operation end; The bottom of the fixed rod 10 is fixedly installed by a torsion spring 11, and the fixed rod 10 is provided with a platform 12 for fixing the limit end of the eccentric wheel lever 9; the upper part of the piston rod 7 passes through...

Embodiment 3

[0032] A time-controlled snap-press type multi-purpose fully enclosed safety valve, comprising a valve body 1 and a valve cover 2; the valve body 1 is provided with an air inlet pipe 3 and an air outlet pipe 4; A valve cavity 5 is arranged above the ventilation hole; the valve cavity 5 is provided with a snap switch; the snap switch is mainly composed of a piston 6, a piston rod 7, a compression spring 8, an eccentric wheel lever 9 and a fixed rod 10 The eccentric wheel lever 9 is installed above the valve cover 2; one end of the eccentric wheel lever 9 is a limit end, the limit end extends to the fixed rod 10, and the other end is a switch operation end; the fixed rod 10 The bottom is fixedly installed by a torsion spring 11, and the fixed rod 10 is provided with a platform 12 for fixing the limit end of the eccentric wheel lever 9; The lever 9 is connected; a silica gel layer 13 is arranged between the piston rod 7 and the compression spring 8, and the two ends of the silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com