Combustion control system of a biomass combustion furnace

A biomass combustion furnace and control system technology, which is applied in the control of combustion, combustion equipment, lighting and heating equipment, etc., can solve problems such as the inability of the blower to ensure the uniform distribution of wind, the inability to perform precise temperature control, and the difficulty in improving combustion efficiency. Easy to implement, uniform air outlet, and temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

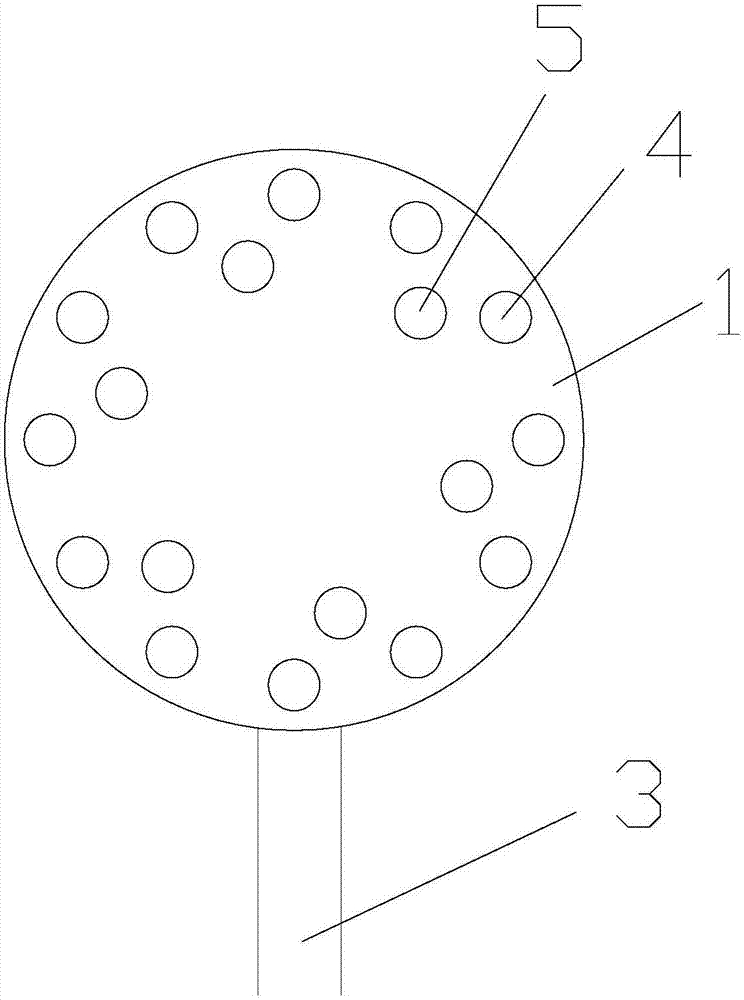

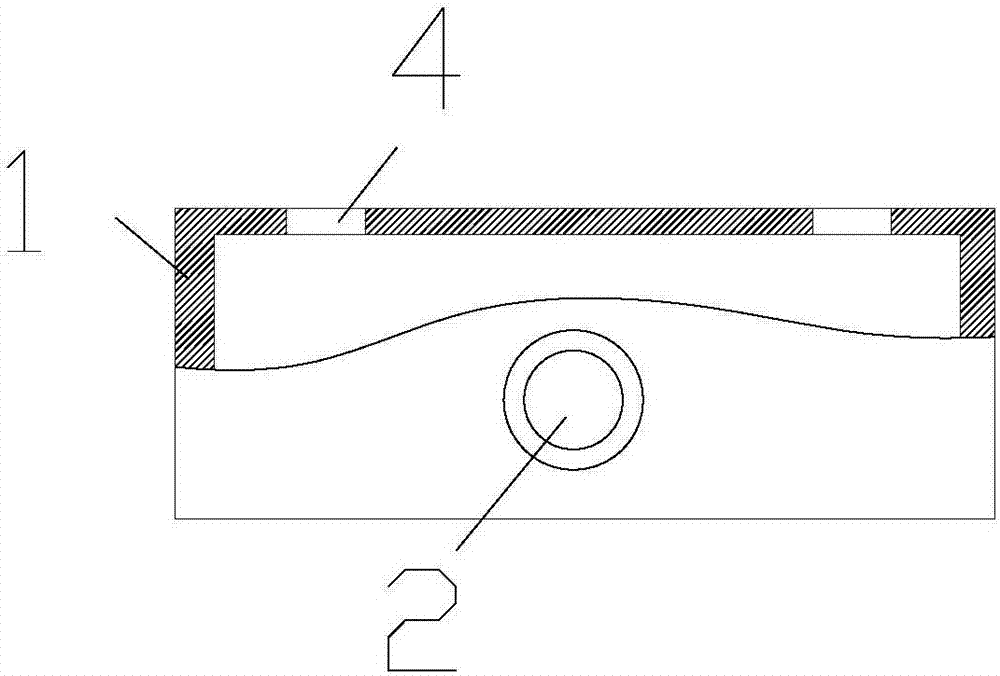

[0019] Embodiment 1: as Figure 1-2 , a combustion control system of a biomass combustion furnace, comprising a furnace body, a blower and an air supply box 1; the air supply box is a cylindrical shape with a cover on the top and a sealed bottom, and the air supply box is arranged at the bottom of the hearth in the furnace body, The top cover of the air supply box is provided with a plurality of exhaust holes; the side wall of the air supply box is provided with an air inlet 2, and the air inlet is connected to the blower through an air inlet pipe 3.

[0020] The exhaust holes are arranged in two rings, the outer ring has 12 outer ring exhaust holes 4, the outer ring exhaust holes are arranged in equal parts along the circumference of the air supply box, and the inner ring has 6 inner ring exhaust holes 5 , The exhaust holes in the inner ring are equally divided along the circumference of the air supply box.

[0021] The combustion control system of the biomass combustion fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com