Noise testing device and testing method for automobile exhaust tail pipe

A technology for noise testing and automobile exhaust, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as inaccurate data, different exhaust noise, and suction cup falling off, so as to improve accuracy and practicability Strong, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

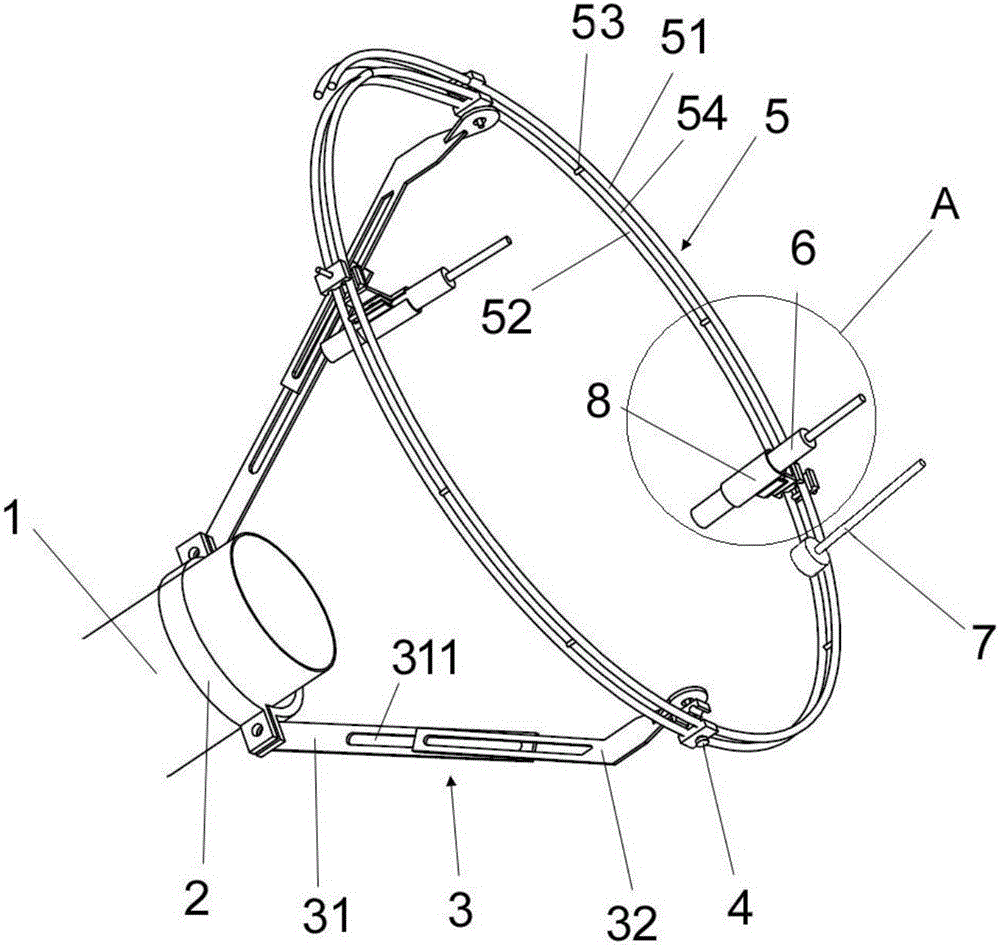

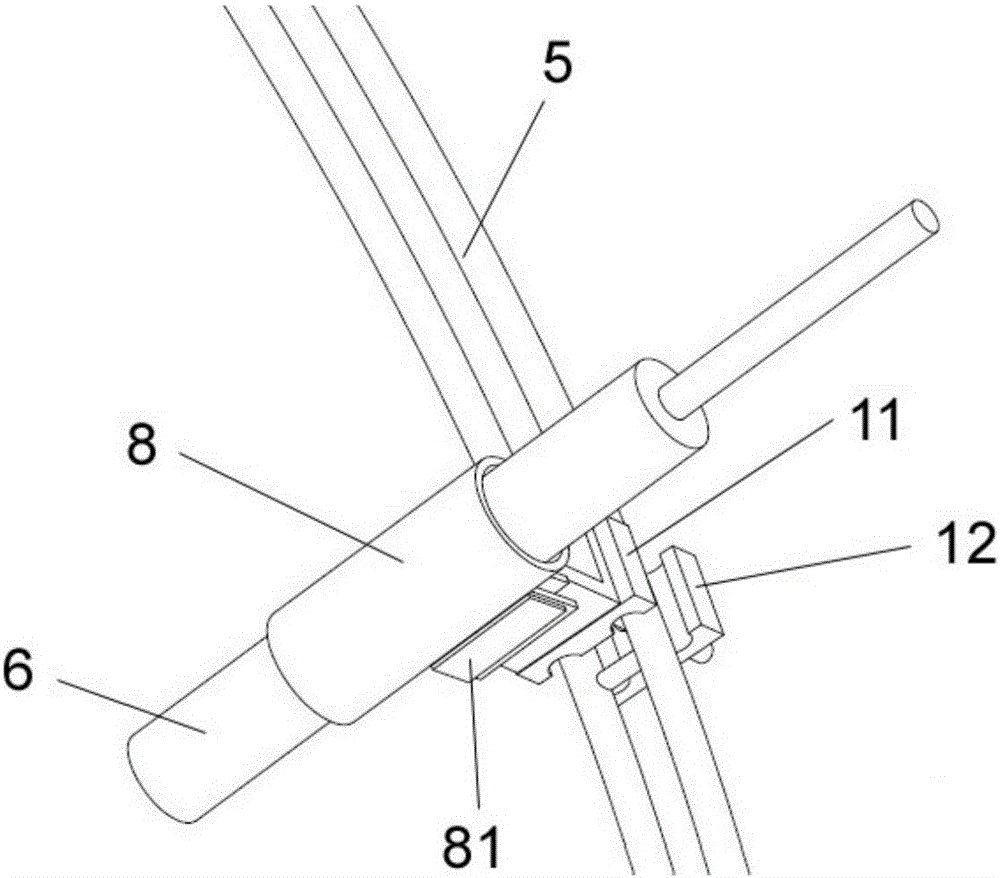

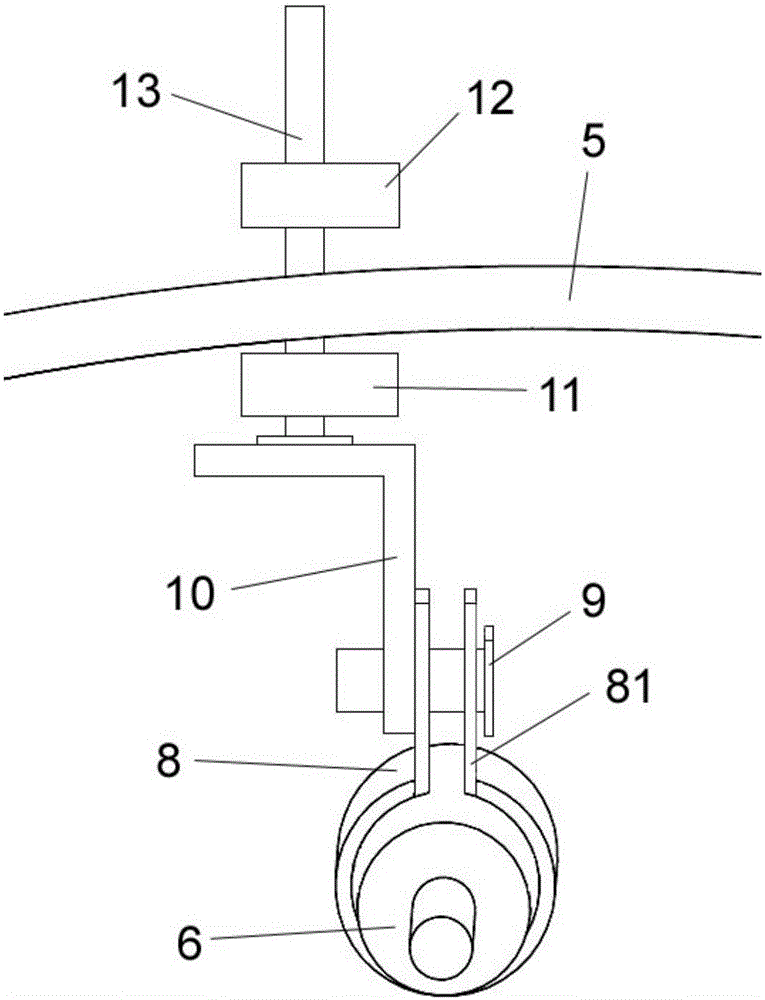

[0028] Such as figure 1 As shown, the automobile exhaust tailpipe noise testing device of the present invention includes an acoustic sensor 6 for collecting the noise data of the exhaust tailpipe and a data processor (not shown) for processing the noise data, and adjacent The acoustic sensor 6 is provided with a temperature sensor 7 . The temperature sensor 7 is used to collect temperature data at the location where the acoustic sensor 6 is located. The collected temperature data and noise data are sent to the data processor, and the data processor judges the validity of the noise data according to the temperature data and performs certain processing on the effective noise data.

[0029] The automobile exhaust tailpipe noise testing device of the present invention also includes a fixing frame 2 and a ring support 5 . The fixing brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com