Adjusting Mechanism of Moment Arm Center of Mass for Micro Torque Standard Device

A technology of torque standard device and center-of-mass adjustment mechanism, which is applied in the direction of measuring device, control/adjustment system, machine/structural component testing, etc. It can solve the problems such as difficult to manually adjust the counterweight method to achieve perfect balance, so as to optimize the position of the center of gravity of the mechanism , Simple structure, realize the effect of self-positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

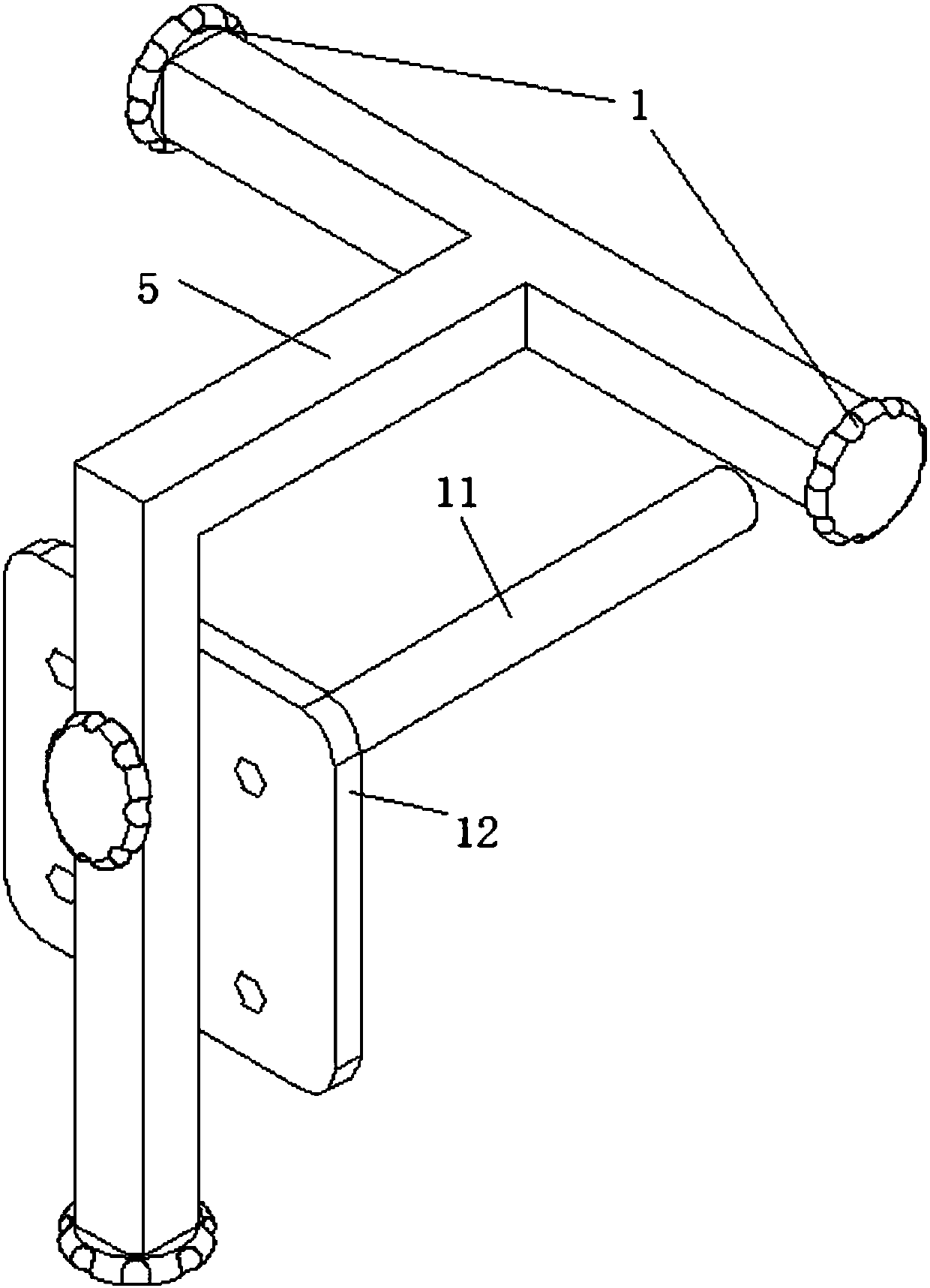

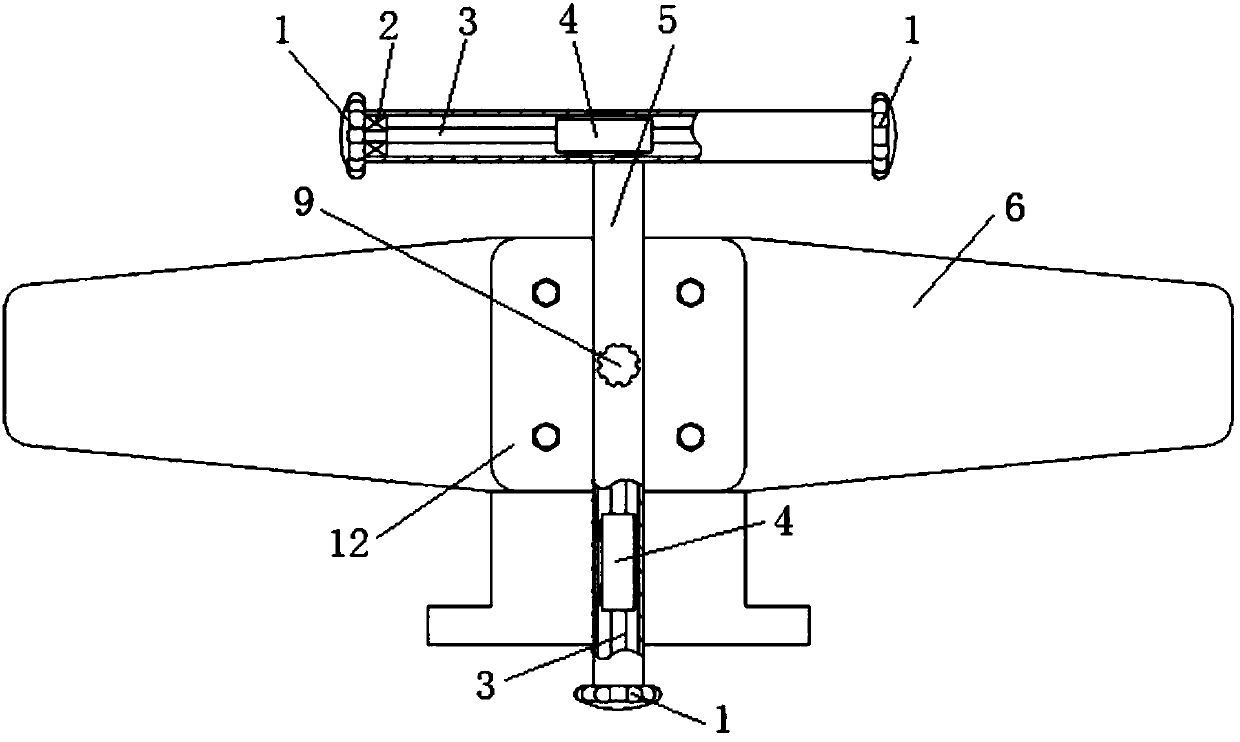

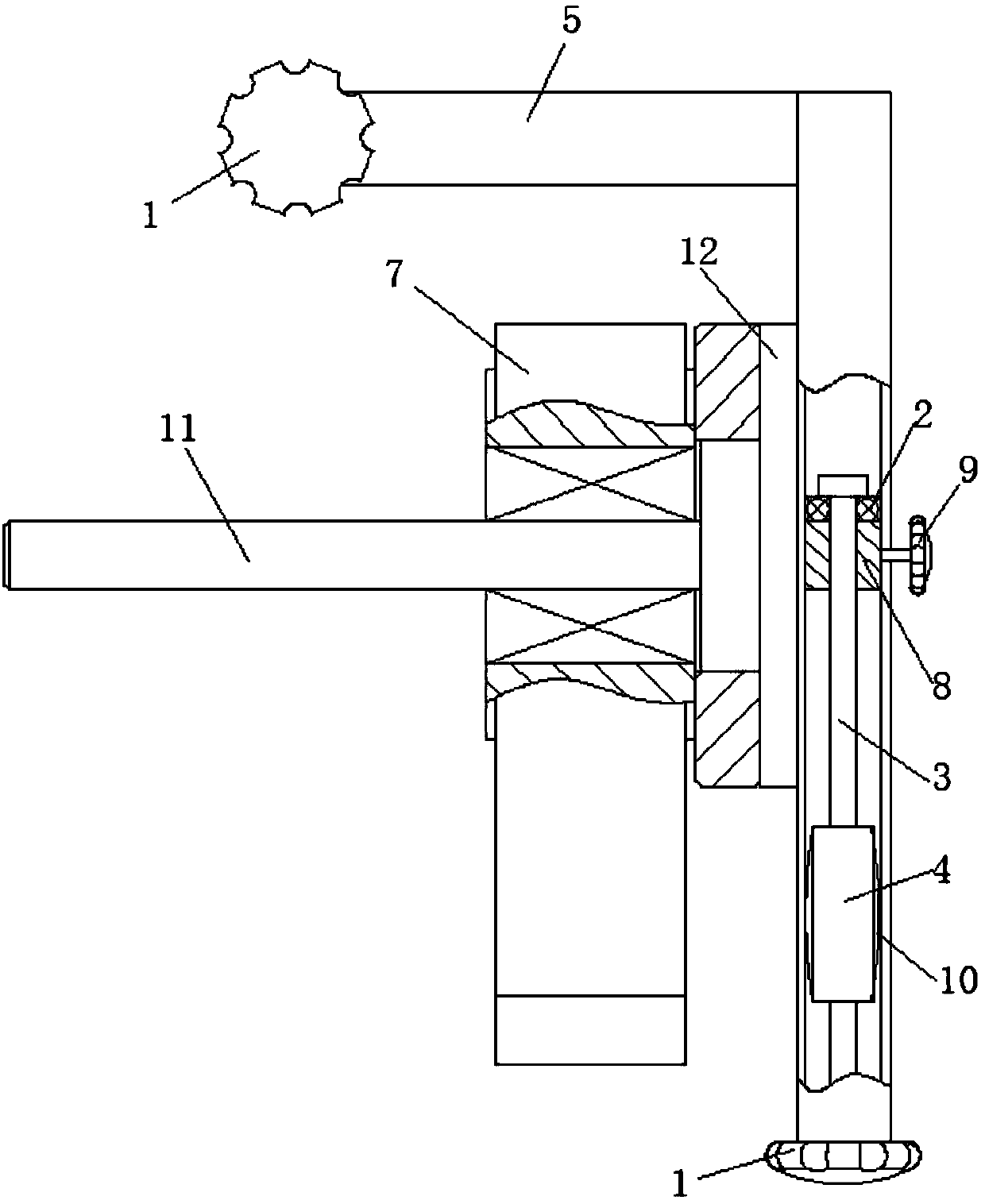

[0016] Below in conjunction with accompanying drawing this patent is described in further detail:

[0017] like Figure 1 to Figure 4 As shown in Fig. 1 , a mechanism for adjusting the center of mass of the moment arm for a small torque standard device is specially suitable for a symmetrical moment arm structure with a small volume. It mainly includes: Adjusting handle 1, counterweight nut 4, screw rod 3, first bearing 2, structural square tube frame 5, leveling arm 6, second bearing 7, positioning block 8, positioning screw 9, friction spring piece 10 , major axis 11, fixed plate 12 is installed.

[0018] The structural square pipe frame 5 is welded by horizontal square pipes, vertical square pipes and intermediate square pipes, wherein the horizontal square pipes are connected to the vertical square pipes through the middle square pipes; The first bearings 2 are installed on both sides, and a screw rod 3 is passed through the middle of the first bearing 2 on both sides. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com