Mechanical shock test equipment

A test equipment and mechanical shock technology, applied in the field of mechanical shock, can solve problems such as inability to obtain various parameters, lack of high-frequency oscillation shock function, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

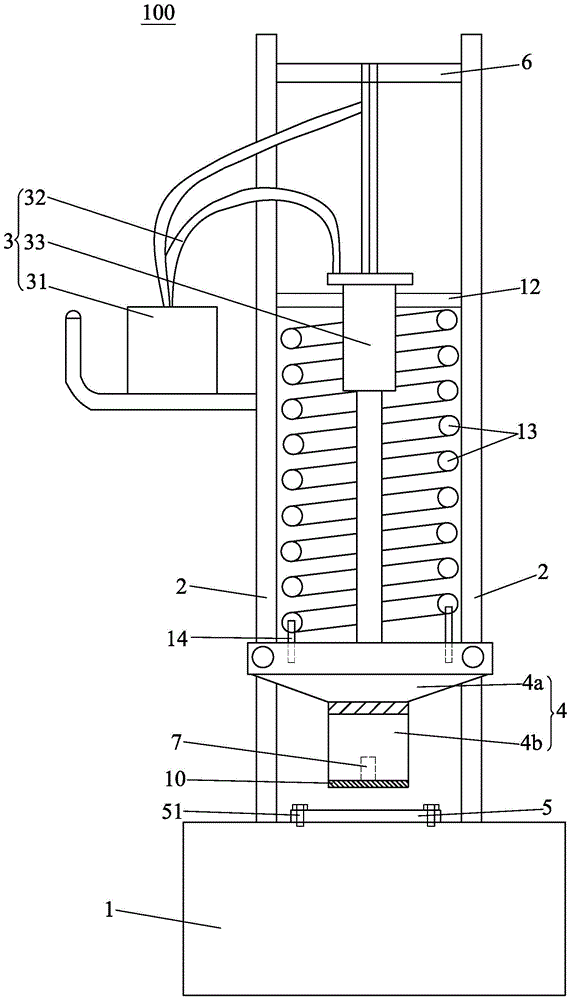

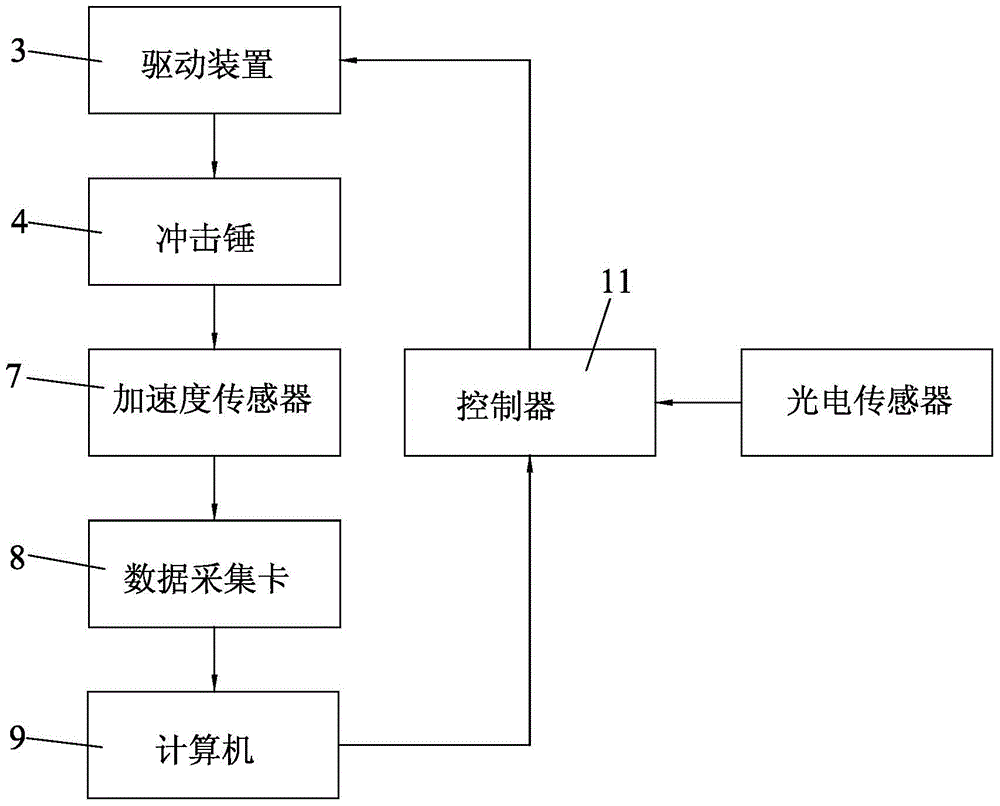

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 In the shown embodiment, the present invention provides a multifunctional mechanical impact test equipment 100 provided by the embodiment, including: a base 1, a guide post 2, a driving device 3, an impact hammer 4, and a backing plate 5, the base 1 is arranged horizontally and The guide post 2 is fixed and upright on the base 1, and the upper end of the guide post 2 is also provided with a crossbeam 6, the height of the crossbeam 6 can be adjusted according to the test requirements, and the impact hammer 4 is sleeved on the The guide post 2 is suspended on the beam 6, the backing plate 5 is arranged on the upper surface of the base 1 and below the impact hammer 4, and the sample (not shown in the figure) is placed on the backing plate 5 , the driving device 3 can drive the impact hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com