A motion parameter identification method for an aircraft panel horizontal automatic drilling and riveting machine

A technology of automatic drilling and riveting machine and wallboard horizontal type, which is applied in the fields of electrical digital data processing, computer-aided design, special data processing applications, etc., and can solve problems such as only considering absolute position accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

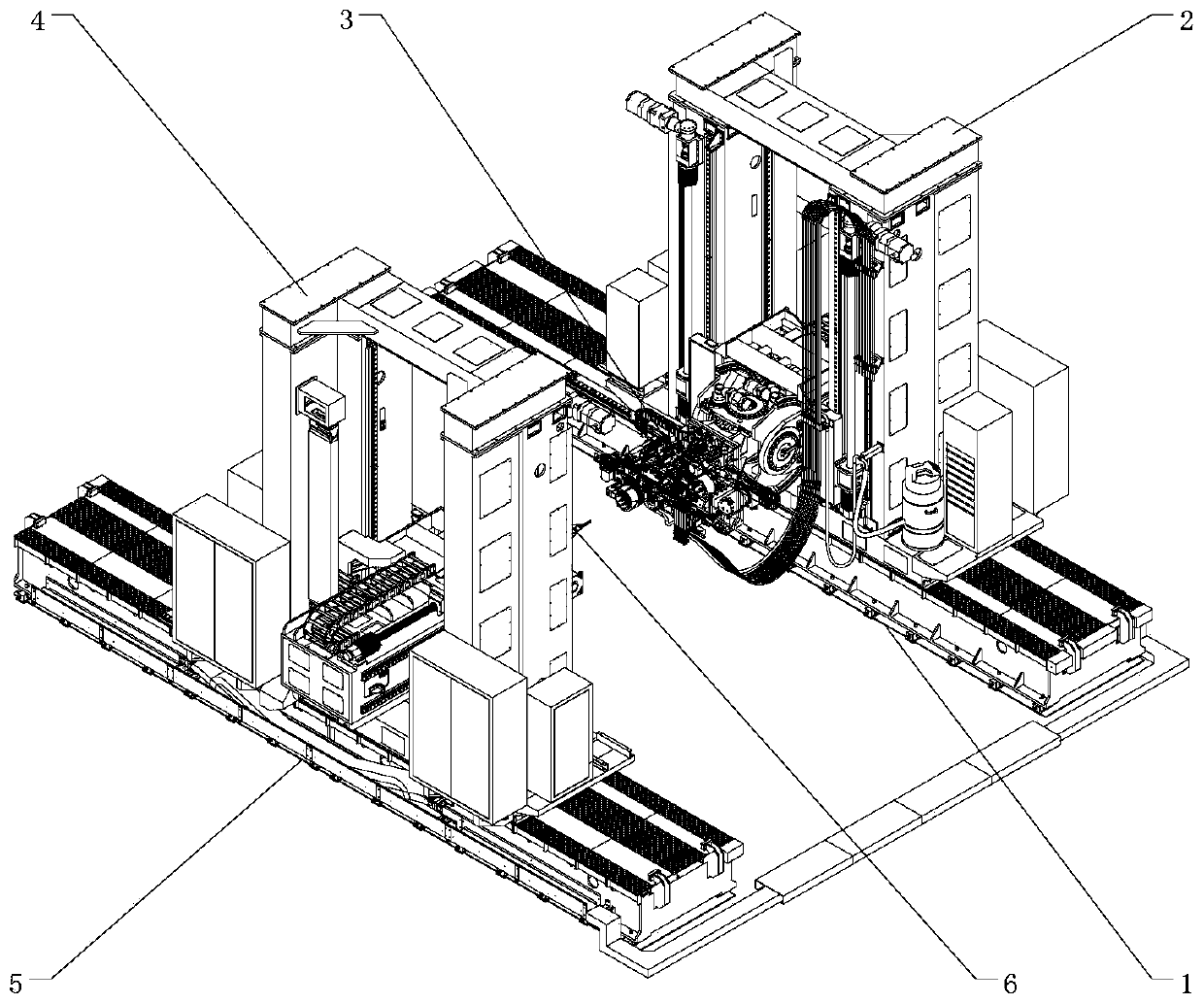

[0059] like Figure 1-Figure 2 As shown, the horizontal automatic drilling and riveting machine for aircraft siding is composed of a hole-making and nail-inserting side machine tool 1 and an upsetting side machine tool 5, wherein the hole-making and nail-inserting side machine tool 1 is composed of a hole-making and nail-inserting side CNC positioning device 2 and a machine tool The hole inserting nail actuator 3 is composed, and the upsetting side machine tool 5 is composed of the upsetting side numerical control positioning device 4 and the upsetting head 6; the aircraft panel is fixed by the panel tooling.

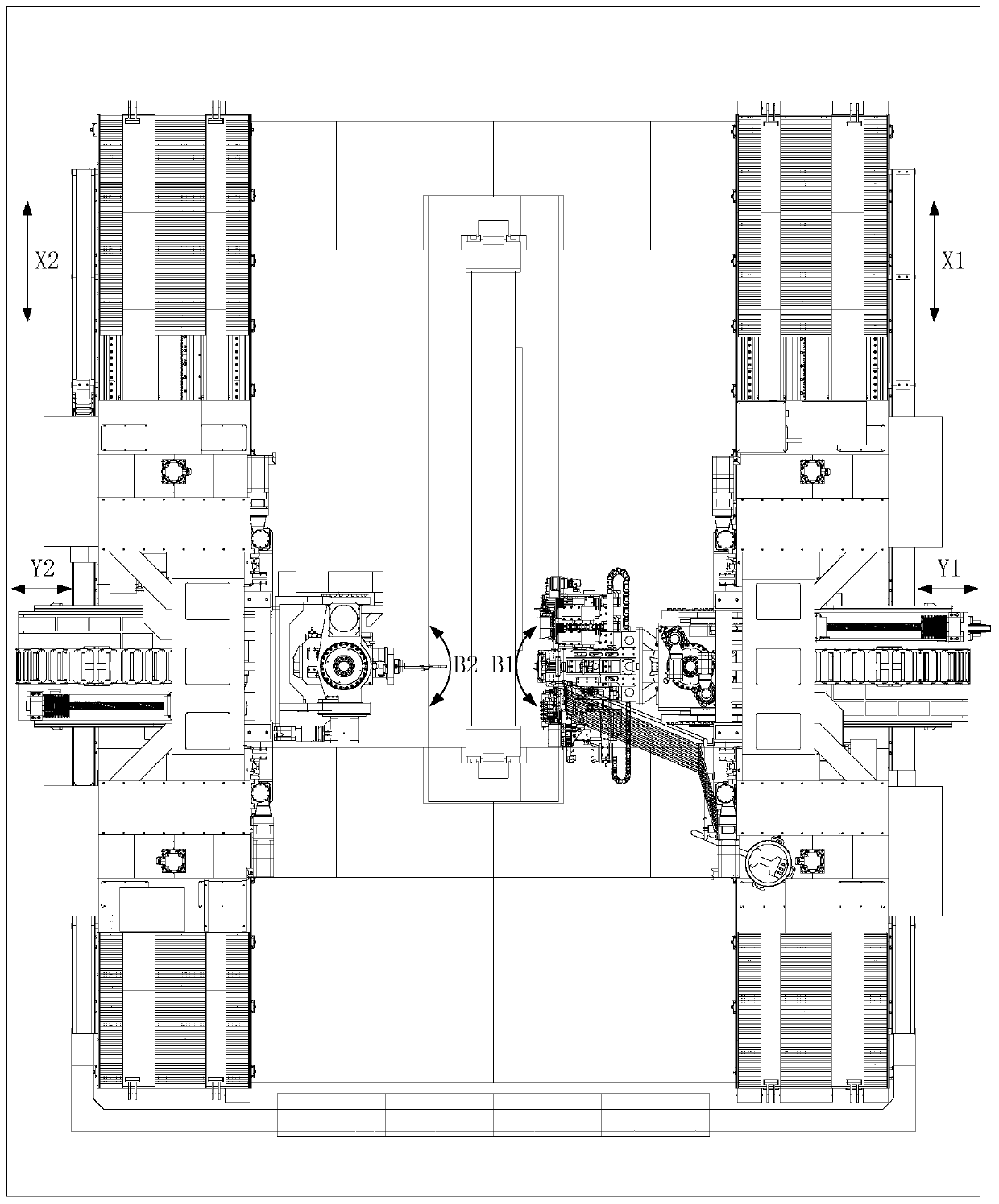

[0060] like image 3 As shown, each CNC positioning device in the horizontal automatic drilling and riveting machine for aircraft panels has five motion axes of X, Y, Z, A, and B, defining each coordinate system and indicating the kinematics modeling process.

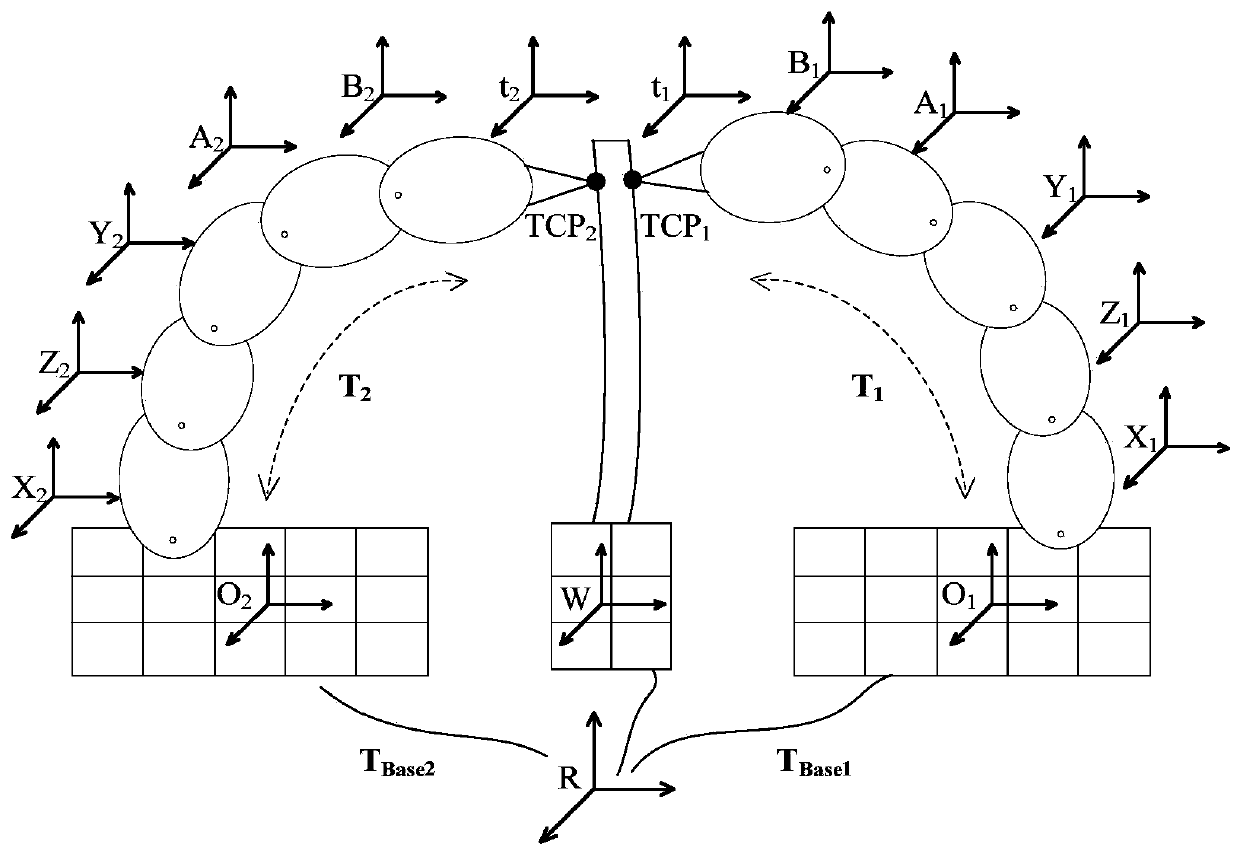

[0061] like Figure 4 As shown, the aircraft panel horizontal automatic drilling and riveting machine is mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com