Motor stator for vehicle

A motor stator and stator technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of welding head occupying a lot of space, achieve effective and rapid heat dissipation, improve stability and reliability, and ensure the effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

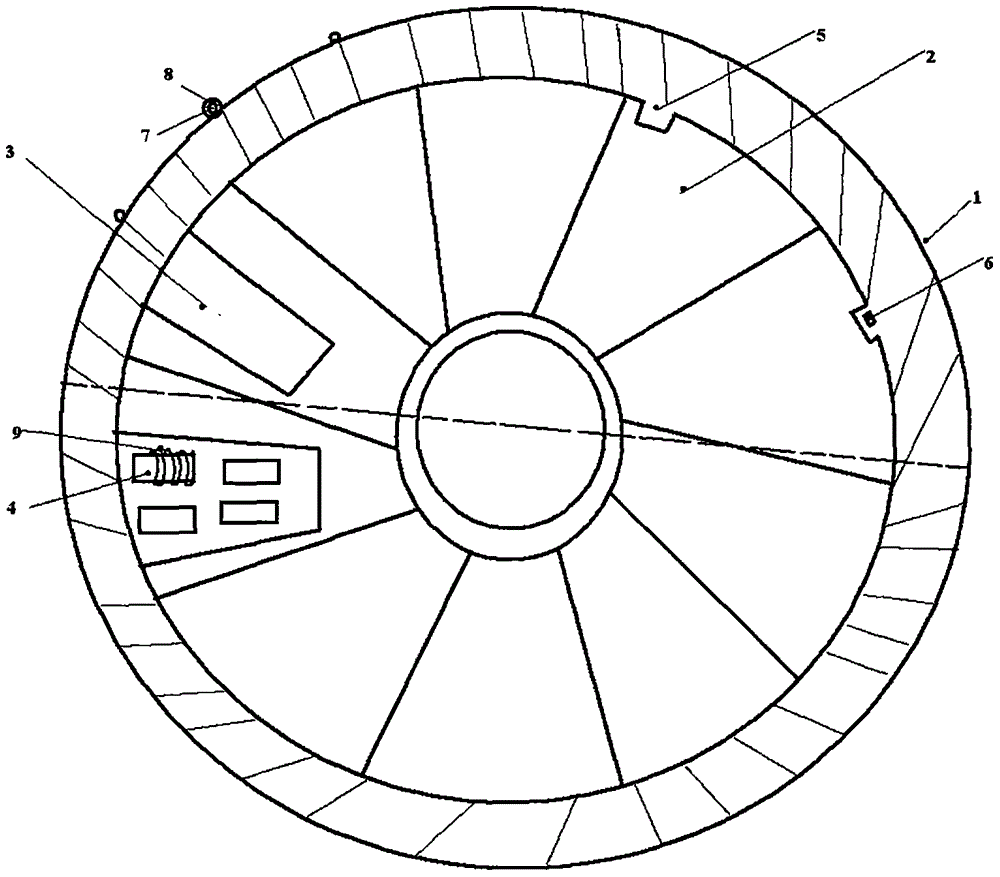

[0018] refer to figure 1 , a motor stator for automobiles, the stator (1) includes a plurality of silicon steel sheets (2) stamped and superimposed on each other, phase grooves (3) are arranged in the silicon steel sheets (2) , the phase groove (3) is provided with a plurality of three-phase winding groups (4) of the stator; the silicon steel sheet (2) is reserved with Hall slots (5), and the Hall slots (5) A Hall element (6) is placed inside; the stator (1) adopts a hemispherical structure, and each stator three-phase winding group (4) includes a plurality of branches (9), and any branch (9) ) is connected to an enamelled coil, and the center point connection ends of any enameled coil are respectively connected by copper rings (7) covered by insulating rings (8), and the copper rings (7) are located in the hemispherical stator (1) In the inner wall. There is also a thermally conductive insulating elastic rubber fixing block between the three-phase winding groups (4) of the ...

Embodiment 2

[0020] refer to figure 1 , a motor stator for automobiles, the stator (1) includes a plurality of silicon steel sheets (2) stamped and superimposed on each other, phase grooves (3) are arranged in the silicon steel sheets (2) , the phase groove (3) is provided with a plurality of three-phase winding groups (4) of the stator; the silicon steel sheet (2) is reserved with Hall slots (5), and the Hall slots (5) A Hall element (6) is placed inside; the stator (1) adopts a hemispherical structure, and each stator three-phase winding group (4) includes a plurality of branches (9), and any branch (9) ) is connected to an enamelled coil, and the center point connection ends of any enameled coil are respectively connected by copper rings (7) covered by insulating rings (8), and the copper rings (7) are located in the hemispherical stator (1) In the inner wall. There is also a thermally conductive insulating elastic rubber fixing block between the three-phase winding groups (4) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com