Hydraulic pipe expanding and enlarging device

A pipe expander and hydraulic technology, applied in the field of pipe expanders, can solve the problems of single function of pipe expanders or pipe expanders, need to be configured separately, and high cost of use, and achieve simple and convenient operation, convenient and fast disassembly and assembly, and reduce The effect of sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

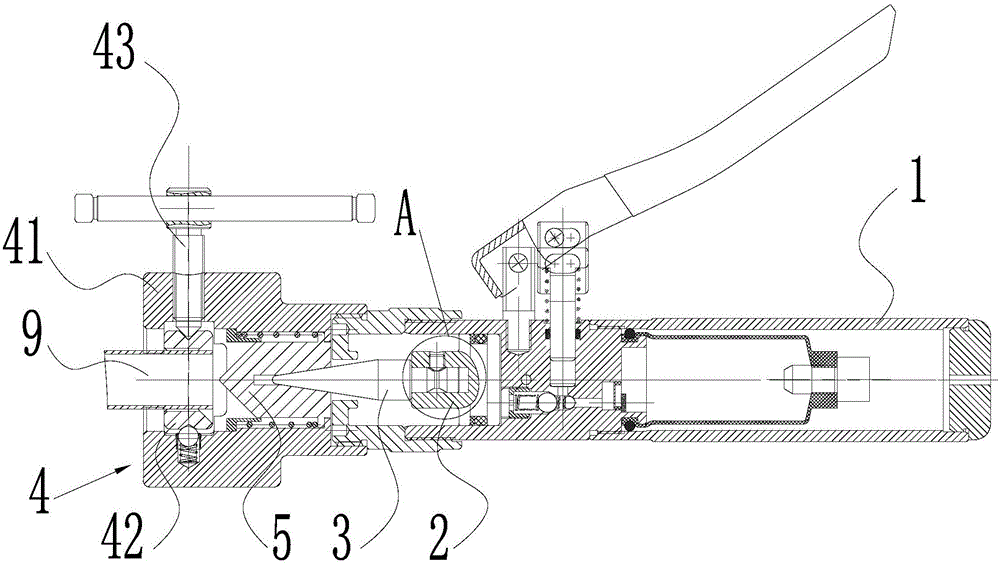

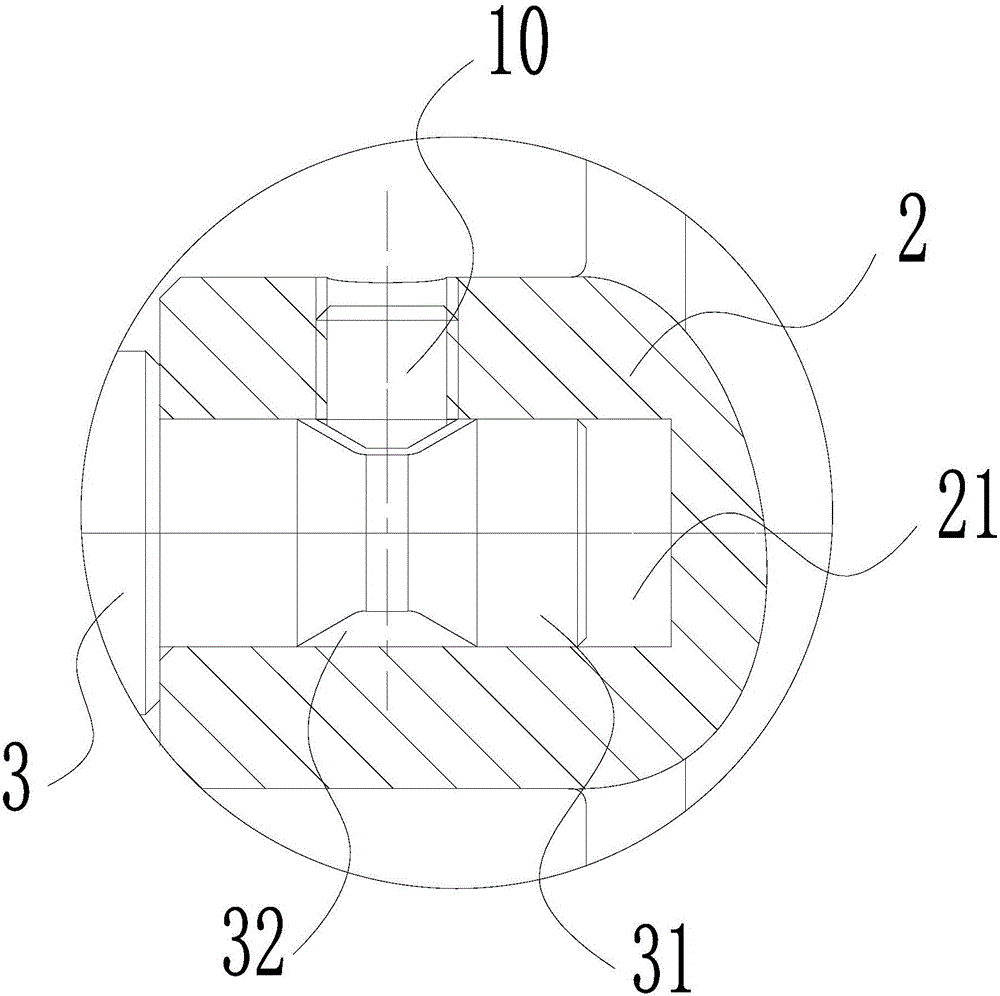

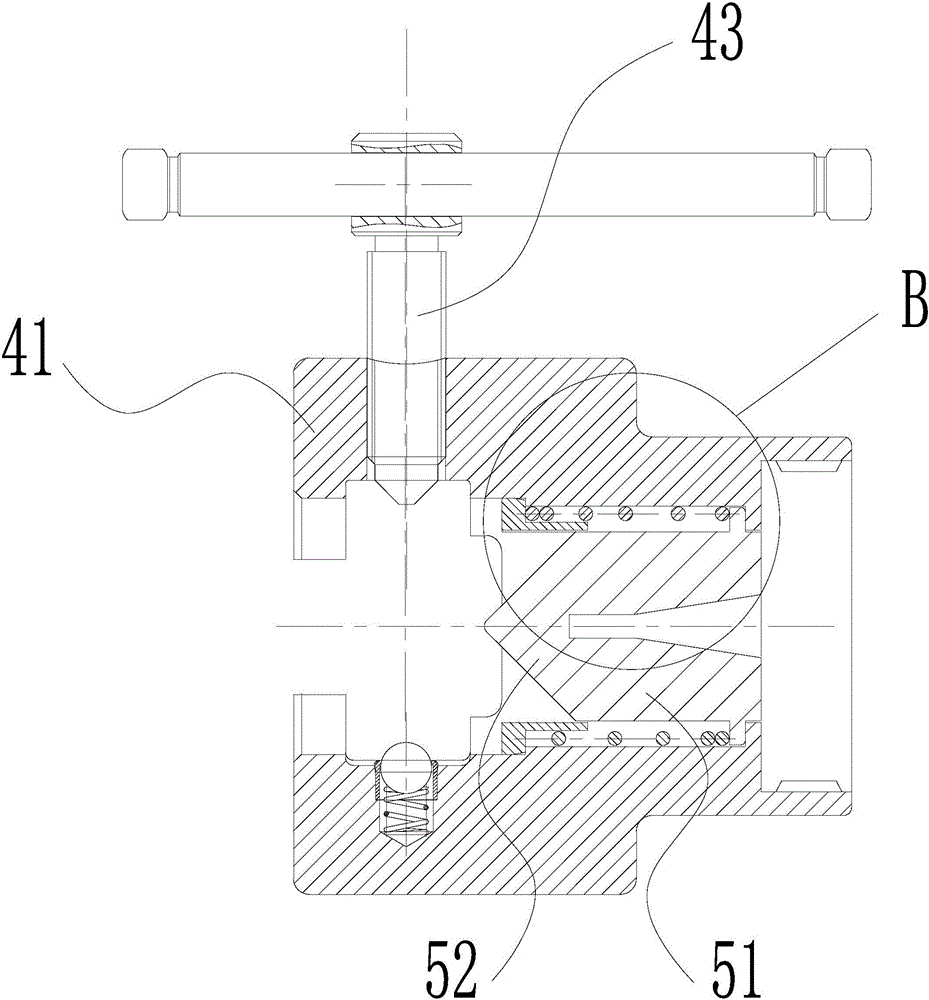

[0021] Such as figure 1 As shown, a hydraulic expander and expander of the present invention includes a circular tubular oil pressure pump 1, a piston 2 is slidably connected to the front port of the oil pressure pump 1, and the expansion tube stem is coaxially connected to the piston 2 3, such as figure 2 As shown, a positioning column 31 is formed by coaxially extending outwardly at the rear end of the expansion tube stem 3 corresponding to the piston 2, and an annular positioning groove 32 is opened on the outer ring surface of the middle part of the positioning column 31, corresponding to the positioning column 31. There is a positioning hole 21 in the middle part of the front end face of the piston 2, and the positioning column 31 is interfitted and inserted in the positioning hole 21, and a positioning stud 10 is screwed radially on the piston 2 corresponding to the annular positioning groove 32, and the positioning stud The inner end of the positioning stud 10 is matc...

Embodiment 2

[0024] After the tube expansion assembly 4 is dismantled as a whole, the expansion tube head is taken and matched with each other at the front end of the expansion tube stem 3 to perform tube expansion processing. All the other parts are identical to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com