Demounted combination-type metallographic specimen high-efficient grinding and polishing clamp

A metallographic sample, grinding and polishing technology, which is applied in the preparation of test samples, sampling, grinding workpiece supports, etc., to achieve the effects of avoiding artificial factors, convenient maintenance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

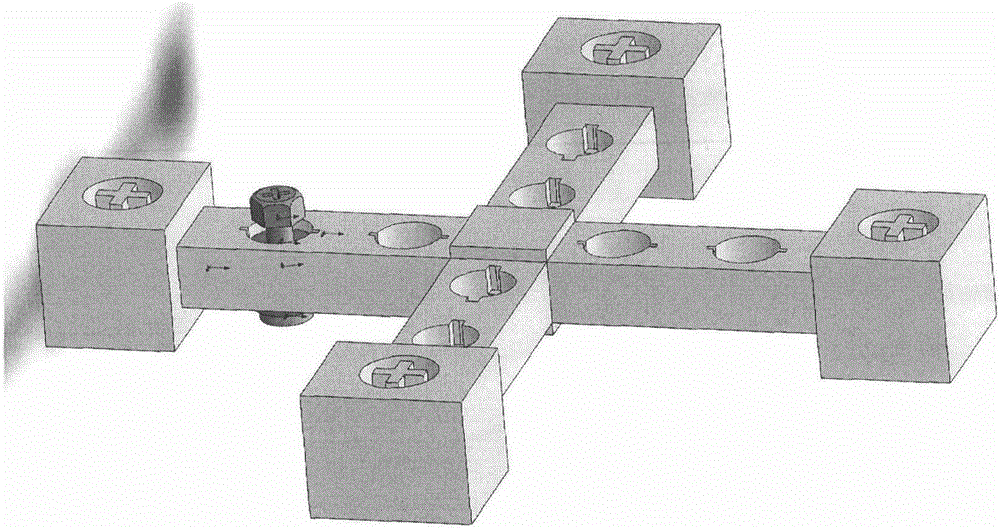

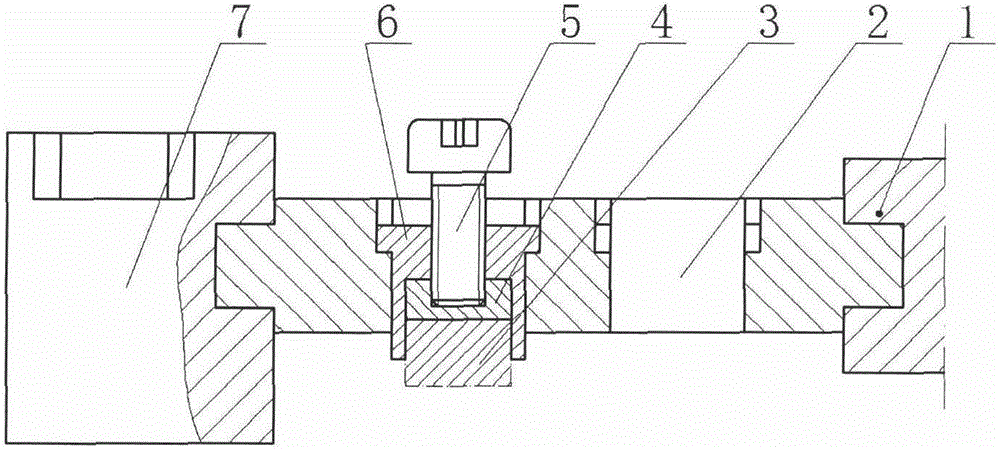

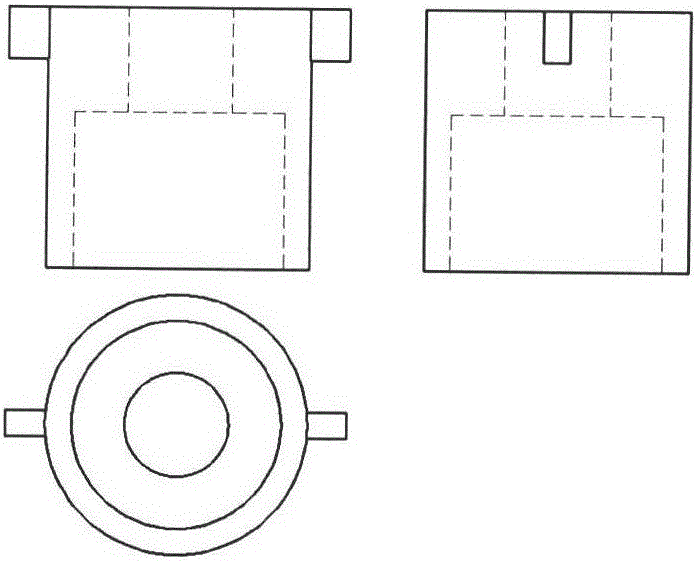

[0023] like Figure 1-5 shown.

[0024] A detachable and combined metallographic sample high-efficiency grinding and polishing fixture. One end of four connecting rods (2) is respectively inserted into the holes around the middle connecting block (1) of a square structure, and the other end is connected with a magnetic sucker (7). Constitute a cross-shaped overall structure fixture; the connecting rod (2) has a hole for placing the metallographic sample holder assembly, and place the metallographic sample holder assembly in the hole when grinding and polishing the sample , and fix it with the screw (5) in the metallographic specimen holder assembly. The connecting block (1) has a square structure, and square through grooves are opened on the front, back, left, and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com