Method for measuring dislocation density of steel through electron back-scattered diffraction (EBSD)

A density and dislocation technology, applied in the field of steel centerline defect testing, can solve problems such as unintuitive, cumbersome process, large sample size, etc., and achieve the effect of accurate and reliable results, simplified process, fast and convenient comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

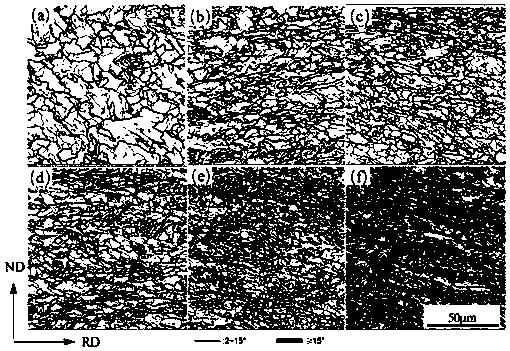

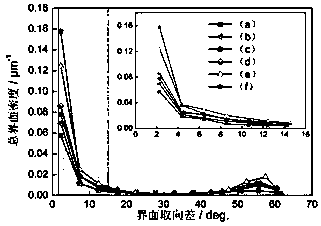

[0034] In Embodiment 1, the steel used is a low-alloy high-strength steel designed with different microalloy elements, smelted, forged, controlled rolling and controlled cooling, and then laminarly cooled to about 400°C, and then air-cooled to room temperature. There are 6 steel types in total. When there are many test samples (more than two), one of the samples can be selected as the standard sample, and the remaining samples can be used as the samples to be tested. In this implementation case, one of the samples is randomly selected as a standard sample, and the rest are used as test samples. The specific implementation method steps of Embodiment 1 are as follows:

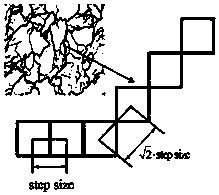

[0035] (1) Sample preparation: use wire cutting to cut a square sheet-shaped sample with a size of 7mm (length) × 7mm (width) × 3mm (thickness), and mark 6 samples of different steel types as (a)~ (f), wherein randomly selected sample (d) is a standard sample, (a), (b), (c), (e), (f) are test samples, and all sa...

Embodiment approach 2

[0042] The specific implementation method steps of the second embodiment are as follows:

[0043] In the second embodiment of the present invention, the alloy composition and production process of the sample to be tested are different from the sample in the first embodiment. The main difference is that the alloy composition is subjected to quenching heat treatment after controlled rolling, and the quenching medium is different. They are oil, water, salt water, and ice salt water respectively, and the cooling capacity is increased sequentially. The tested sample is low-alloy high-strength steel containing Cu. The post-rolling heat treatment processes are: (a) 900℃×1h+oil cooling, (b) 900℃ ℃×1h+water cooling, (c)900℃×1h+brine cooling, (d)900℃×1h+ice brine cooling.

[0044] The sample of the second embodiment is carried out as steps (1) to (4) in the first embodiment, and the interface diagram after EBSD scanning is as follows Figure 5 As shown in , it can be seen that the smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com