Sampling device and sampling method of geosynthetics biaxial tensile test

A technology of geosynthetics and biaxial stretching, which is applied in the direction of measuring devices, analysis materials, and preparation of test samples. Destruction in advance, improving the efficiency of sample preparation, and the effect of completely consistent shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

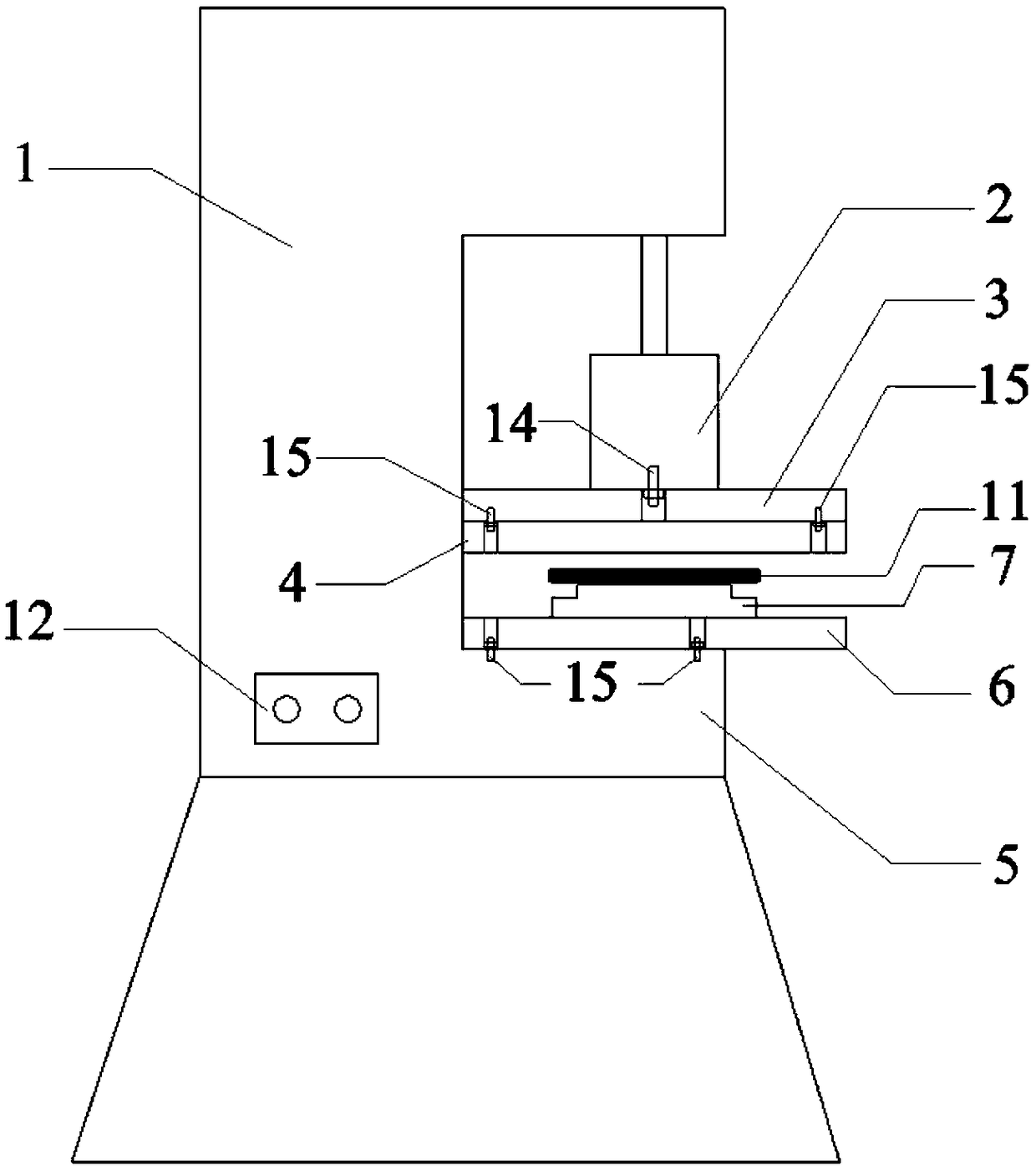

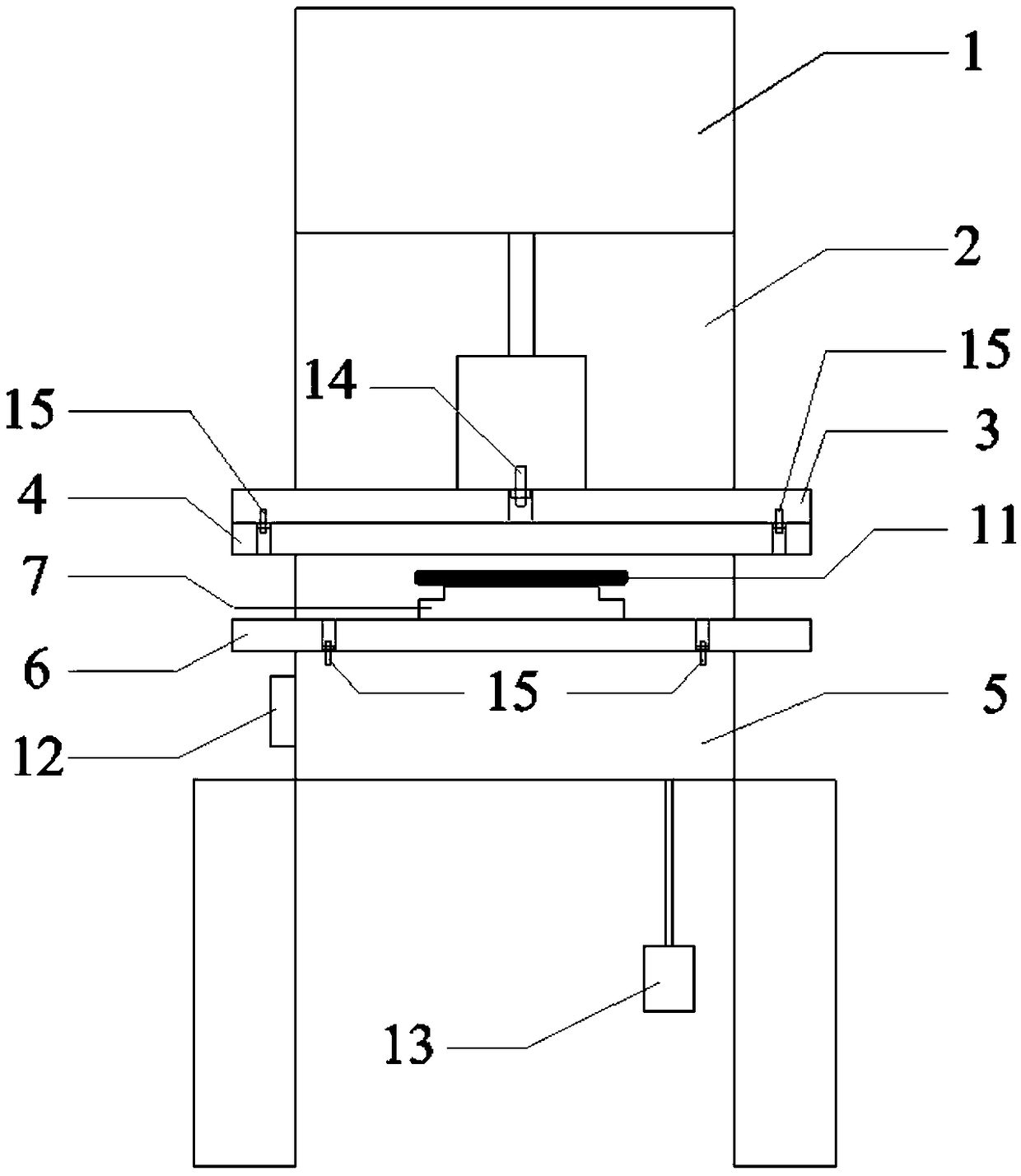

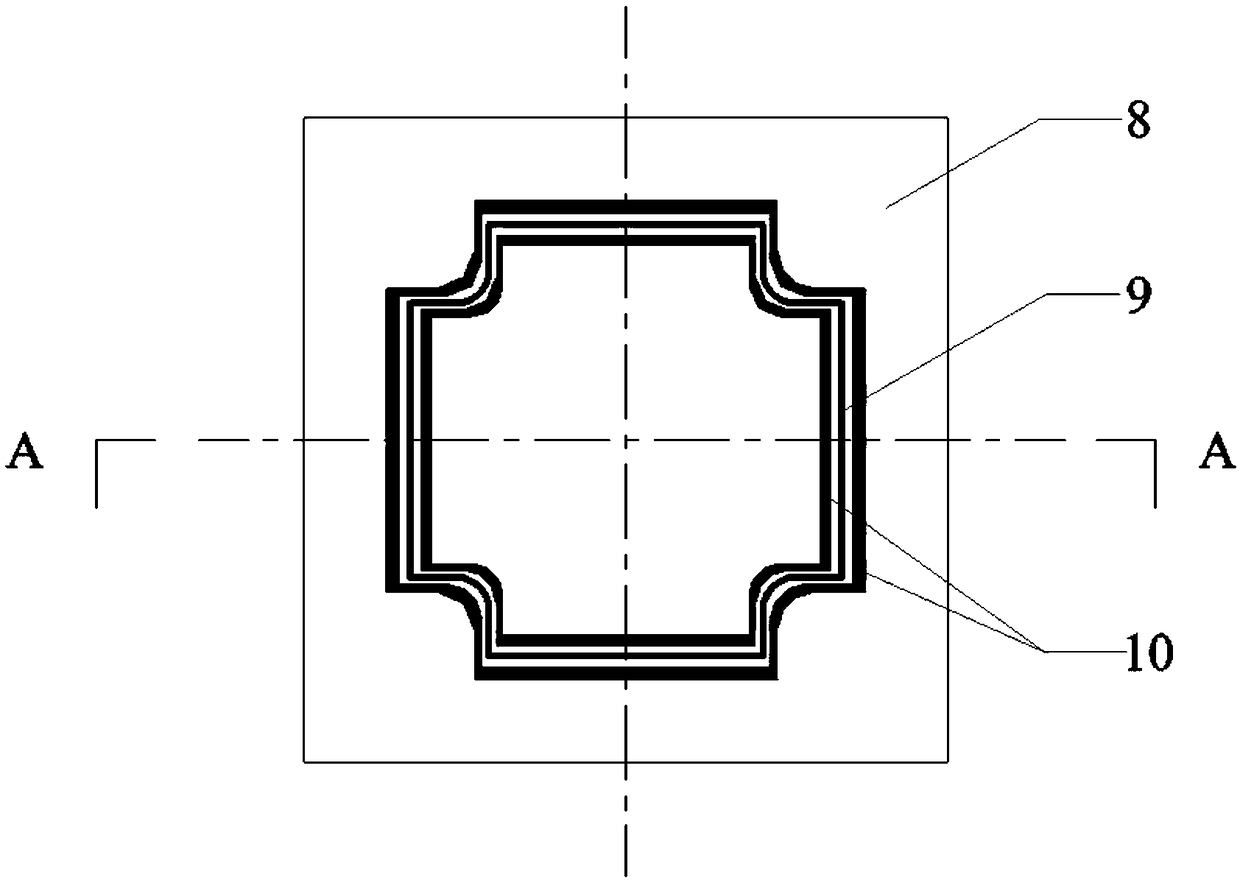

[0022] Such as Figure 1-4 As shown, the sample preparation device for bidirectional tensile test of geosynthetics includes: a punching machine 1 with a punch 2 and a punching platform 5, a loading plate 3 installed and fixed under the punch 2, a punching machine installed and fixed under the loading plate 3 The plate 4, the base plate 6 installed and fixed on the stamping platform 5, and the mold 7 placed between the stamping plate 4 and the base plate 6 during sample preparation.

[0023] The loading plate 3 is a square steel plate with a thickness of 1 cm and 30 cm × 30 cm. The loading plate is a square rigid plate. It is fixed on the lower surface of the punch 2 of the punching machine 1 through a large bolt 14 at its center, and its function is to transmit vertical punching. While loading, increase the application range of the stamping load so that it can be even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com