Intelligent reduction treatment system and method for wet garbage

A processing system and technology for waste, applied in dry cargo processing, sustainable biological processing, chemical instruments and methods, etc., can solve the problems of difficulty in adapting to small waste rooms in vegetable farms, high energy consumption and high reduction rate, and achieve moderate prices. , The design layout is compact, the equipment operation noise is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

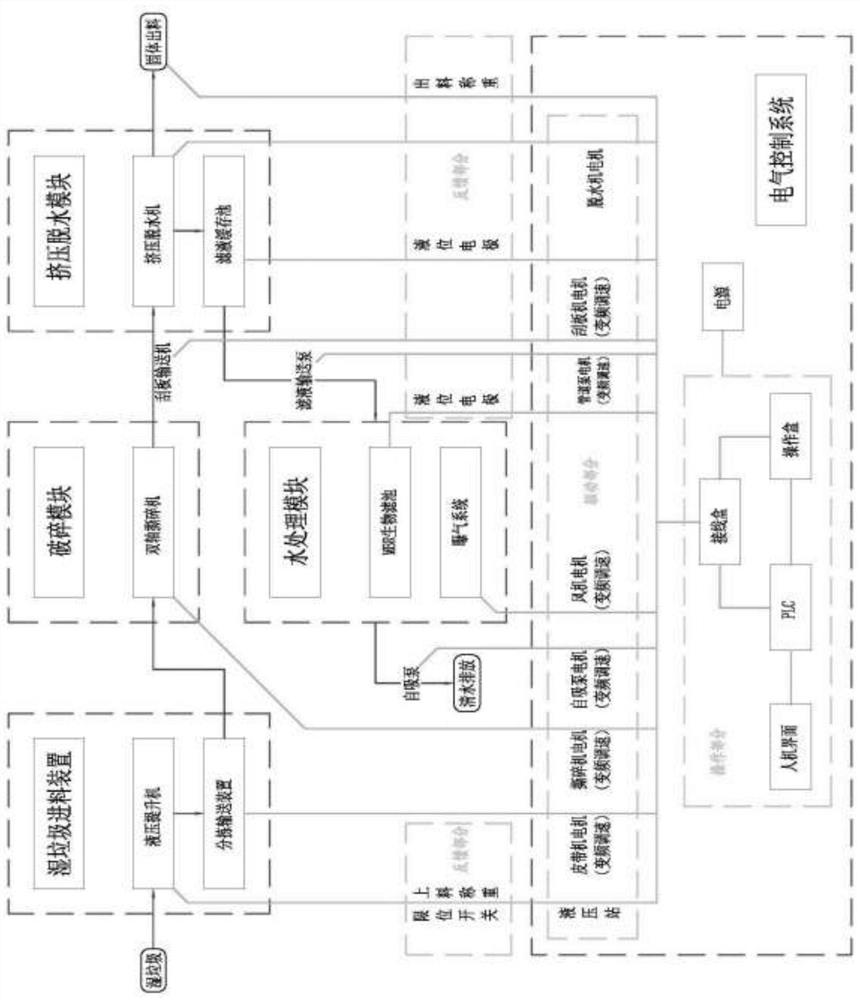

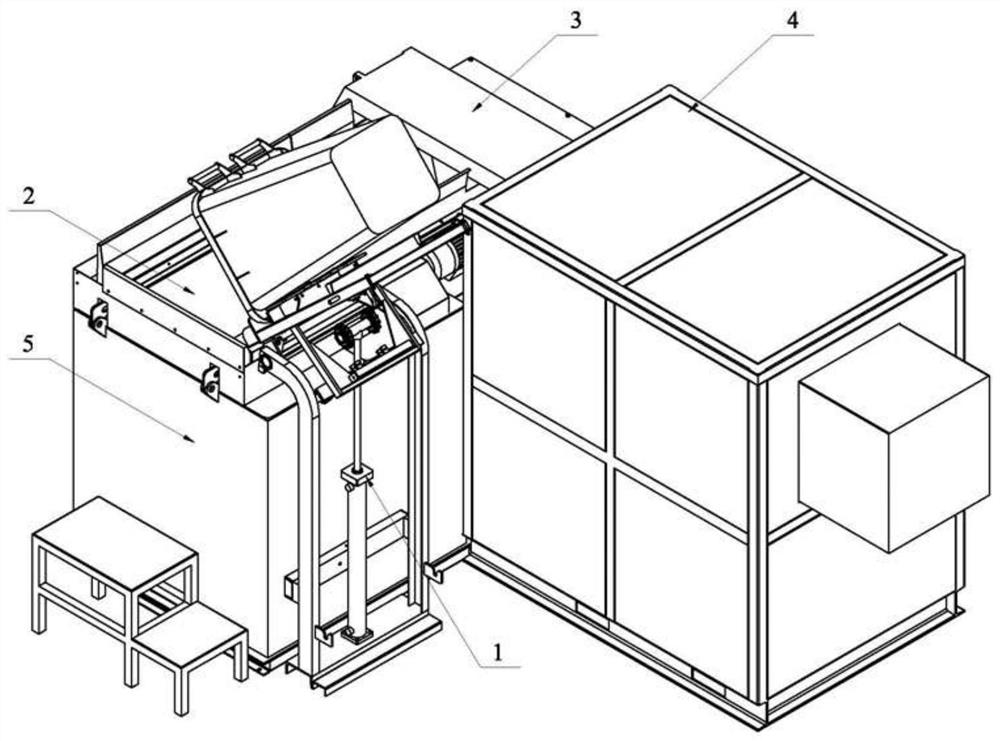

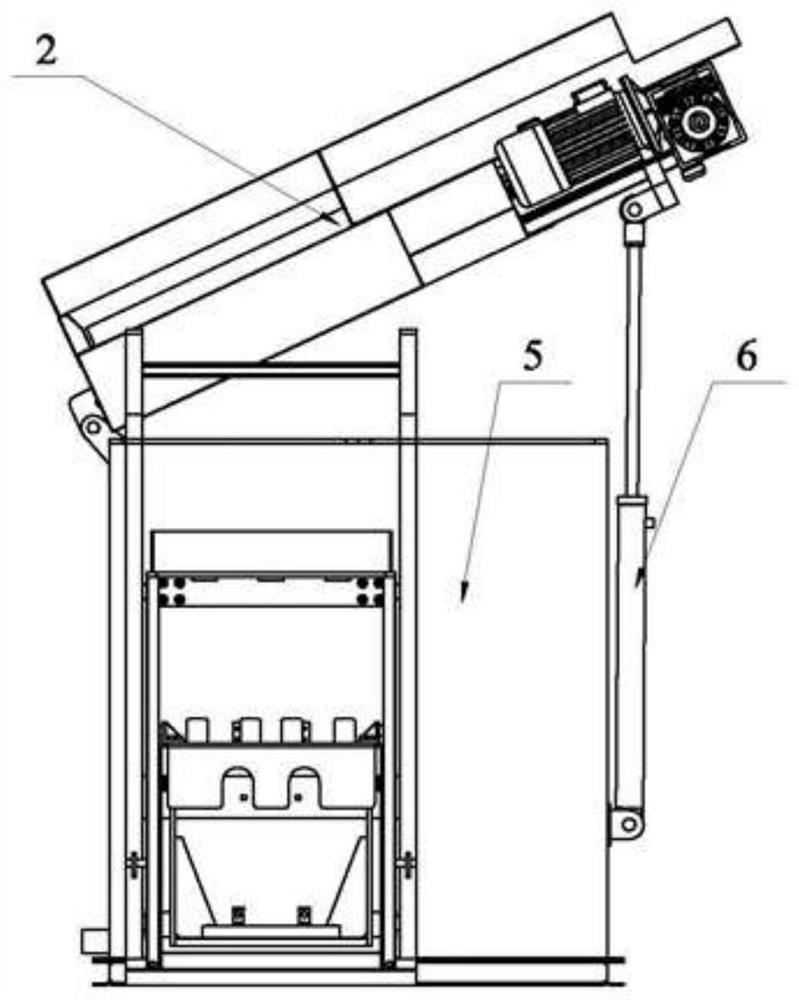

[0042] Such as Figure 1-Figure 6 As shown, a wet garbage intelligent reduction treatment system of the present invention is a miniaturized intelligent wet garbage on-site reduction treatment system suitable for the vegetable farm environment, modular assembly, high integration, and has the functions of material crushing, dehydration, filtrate Purification, data collection and other functions; mainly include wet garbage feeding device, crushing module 3, extrusion dehydration module 4, water treatment module 5 and electrical control system; the electrical control system is connected with the above modules and wet garbage feeding device; among them , the wet garbage feeding device mainly includes a garbage bin elevator 1, a sorting and conveying device 2; the sorting and conveying device 2 includes a transmission mechanism and a conveyor belt; the crushing module mainly includes a double-shaft shredder 7; Press dehydrator 9, filtrate buffer tank 10; the discharge port of sortin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com