Bamboo cutting with hammer grain effect and preparation method thereof

A technology of inserting bamboo and hammer pattern, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficulty in forming interest relations in coating factories, difficulty in obtaining coatings, and small amount of coatings, etc., to achieve easy operation, easy acquisition, and reduction The effect of raw material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

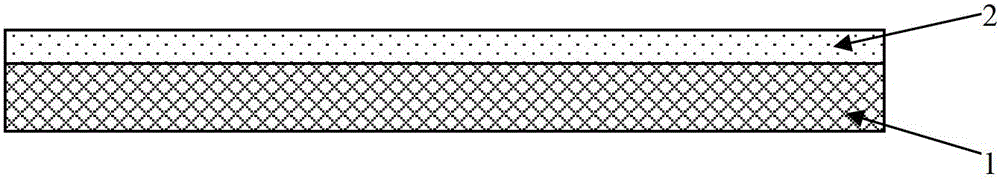

[0050] refer to Figure 1-2 , a yellow hammer-effect polypropylene bamboo insert, comprising a polypropylene substrate 1 and a yellow hammer-effect coating 2 .

[0051] Preparation of hammer paint: take 94.2 parts of polyurethane varnish, 0.6 parts of SP-903 polysiloxane hammer grain additive, 4.2 parts of 9526 non-floating aluminum powder, 0.4 parts of BentoneSD-2 montmorillonite organic derivative thixotropic anti-settling agent 0.6 parts of yellow color paste; first mix the main agent of polyurethane varnish and thixotropic anti-sedimentation agent with a high-speed disperser at a speed of 2000r / min for 5 minutes to disperse evenly, then add non-leafing aluminum powder and color paste with a high-speed disperser Keep the speed of 2000r / min for 10 minutes to disperse evenly, and finally add the hammer grain additive and keep it for 2 minutes to disperse evenly to get the hammer grain paint.

[0052] The preparation method is as follows:

[0053] (1) Substrate treatment: pret...

Embodiment 2

[0057] refer to image 3 , a blue hammer effect wood cutting, comprising a wood base and a blue hammer effect coating.

[0058] Preparation of hammer paint: Take 91.8 parts of polyurethane varnish, 0.6 parts of SP-903 polysiloxane hammer grain additive, 4.2 parts of 9526 non-floating aluminum powder, 0.4 parts of BentoneSD-2 montmorillonite organic derivative thixotropic anti-settling agent 1 part, 2.6 parts of blue color paste, 0.4 part of black color paste; first mix the main agent of polyurethane varnish and thixotropic anti-settling agent with a high-speed disperser at a speed of 2000r / min for 5 minutes to disperse evenly, then add non-leafing aluminum powder and Use a high-speed disperser at a speed of 2000r / min to maintain the color paste for 10 minutes to disperse evenly, and finally add hammer grain additives and keep for 2 minutes to disperse evenly to obtain hammer grain paint.

[0059] The preparation method is as follows:

[0060] (1) Substrate treatment: pretrea...

Embodiment 3

[0064] refer to Figure 4 , a magenta hammer effect nylon bamboo insert, comprising a nylon base and a blue hammer effect coating.

[0065] Preparation of hammer paint: take 91.3 parts of polyurethane varnish, 0.6 parts of SP-903 polysiloxane hammer grain additive, 4.2 parts of 9526 non-floating aluminum powder, 0.4 parts of BentoneSD-2 montmorillonite organic derivative thixotropic anti-settling agent 1 part of plum red paste, 0.5 part of blue color paste, 0.4 part of black color paste, 1.6 part of white color paste; first mix the main agent of polyurethane varnish and thixotropic anti-settling agent with a high-speed disperser at 2000r / min to maintain 5 Minutes to disperse evenly, then add non-leafing aluminum powder and color paste and use a high-speed disperser at a speed of 2000r / min to maintain 10 minutes to disperse evenly, finally add hammer grain additives and keep 2 minutes to disperse evenly to obtain hammer grain paint.

[0066] The preparation method is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com