Clamp

A fixture and splint technology, which is applied in the direction of clamping, manufacturing tools, workpiece clamping devices, etc., can solve problems such as warping and easy inclination of workpieces to be processed, and achieve the effect of eliminating defective products and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

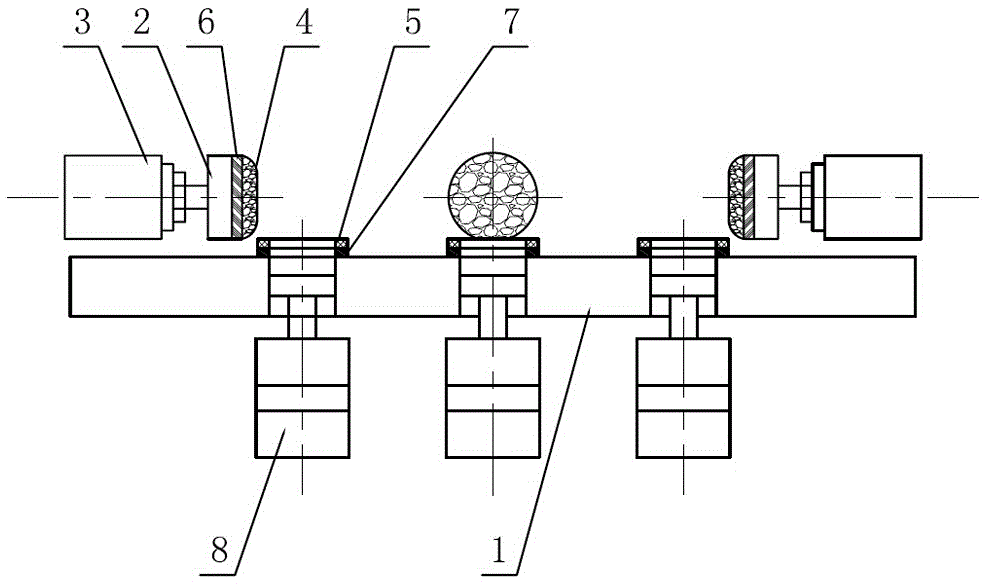

[0015] Such as figure 1 As shown, the structural schematic diagram of the present invention includes a workbench 1 for placing workpieces to be processed and a plurality of splints 2 for fixing the workpieces to be processed in the horizontal direction. As a preferred solution of the present invention, four splints 2 are provided, and the four splints 2 form a square and are distributed around the workpiece to be processed. The back of each splint 2 is respectively connected with a controllable cylinder 3 for controlling the stroke of the splint 2, and multiple splints 2 cooperate to clamp the workpiece to be processed. Second pressure sensors 6 are provided on the working surfaces where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com