Transmission front assembly detachment tool which is used for remanufacturing of automatic transmission and provided with handle

A technology for automatic transmission and disassembly tools, which is applied to manufacturing tools, hand-held tools, etc., can solve problems such as damage, high noise, inconvenience, etc., and achieve the effect of good reliability and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

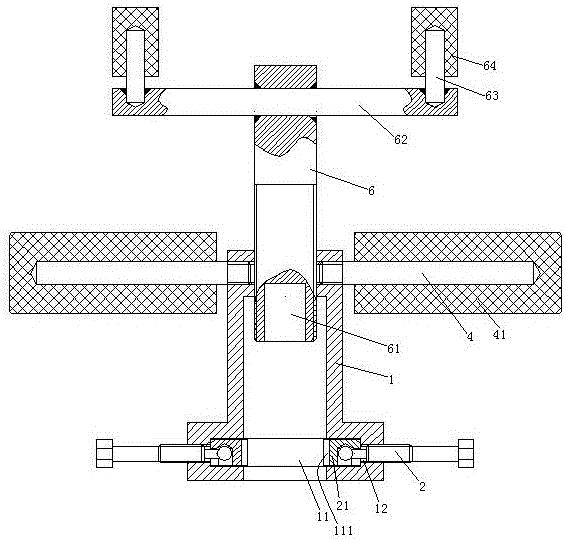

[0031] Embodiment one, see figure 1 , a transmission front assembly removal tool with a handle for automatic transmission remanufacturing, comprising a sleeve 1 . The lower end of the inner peripheral surface of the sleeve 1 is provided with an annular groove 11 . The annular groove 11 is provided with two threaded holes 12 . The threaded hole 12 runs through the sleeve 1 . The threaded holes 12 are symmetrically distributed on both radial sides of the sleeve 1 . The threaded hole 12 is threadedly connected with the clamping rod 2 . The inner end of the clamping rod 2 is clamped with a clamping block 21 . The clamping block 21 and the clamping rod 2 are rotatably connected together. The clamping block 21 has an arc-shaped clamping surface 211 . The axis of the clamping surface 211 is parallel to the axis of the sleeve 1 . The depth of the sleeve 1 is symmetrically provided with two holding rods 4 . The grip bar 4 is perpendicular to the sleeve 1. 4 sets of grip bars a...

Embodiment 2

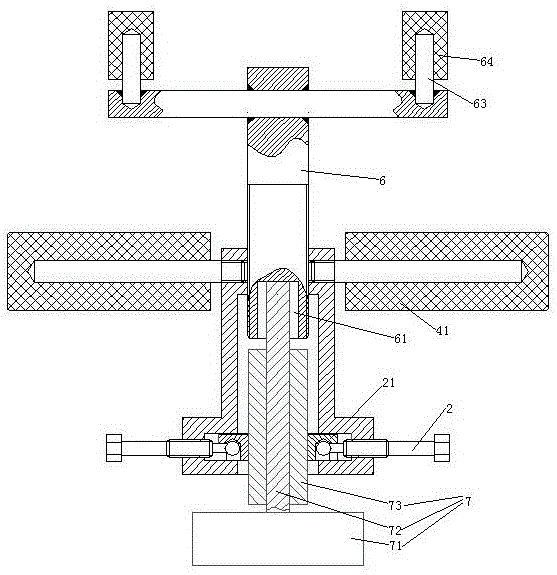

[0034] Embodiment two, the difference with embodiment one is:

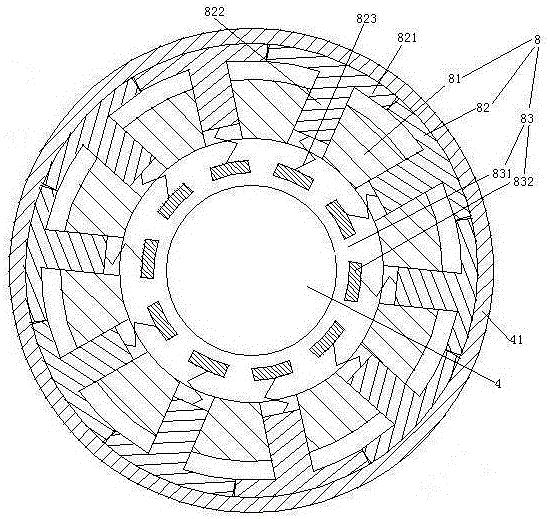

[0035] see image 3 , An elastic adjustment mechanism 8 is provided between the grip bar 4 and the handle cover 41 . The elastic force adjustment mechanism 8 includes a base pipe 81 , a clamping layer 82 and a preload adjustment structure 83 . The base pipe 81 is sheathed outside the handle bar 4 . The base pipe 81 is passed through the handle glove 41 . The clamping layer 82 is composed of several friction strips 821 . The friction strips 821 are distributed along the circumferential direction of the base pipe 81 . The friction strip 821 is provided with a plurality of slide bars 822 axially distributed along the radial extension of the base pipe. The sliding rod 822 slides through the base tube 81 . The inner end of the sliding rod 822 is provided with a third spring 823 . The third spring 823 drives the friction strip to abut against the handle glove 41 through the slide bar. The outwardly moving preloa...

Embodiment 3

[0038] Embodiment three, the difference with embodiment two is:

[0039] see Figure 5 , also includes motor 5 and power switching mechanism 9. The motor 5 includes a motor housing 51 and a motor shaft 52 . The motor housing 51 is fixedly connected with the driving arm 62 . The motor casing 51 is provided with the connection terminal 3 . The push rod 6 is connected to one end of the motor shaft 52 through a reducer 53 . The other end of the motor shaft 52 passes through the driving arm 62 .

[0040] see Figure 6 , The power switching mechanism 9 includes a switch 91 , a pressing rod 92 , a latch 93 and an insertion spring 94 . The switch 91 and the pressing rod 92 are located on both sides of the latch 93 . The switch 91 is fixed inside the drive arm 62 . Switch 91 is a push switch, because the control motor 5 starts and stops. The pressing rod 92 passes through the driving arm 62 . The pin 93 is slidably connected in the driving arm 62 . The motor shaft 52 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com