Active-softening mechanism of hydraulic robot

A hydraulic robot, active and flexible technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of unstable upper platform and large contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

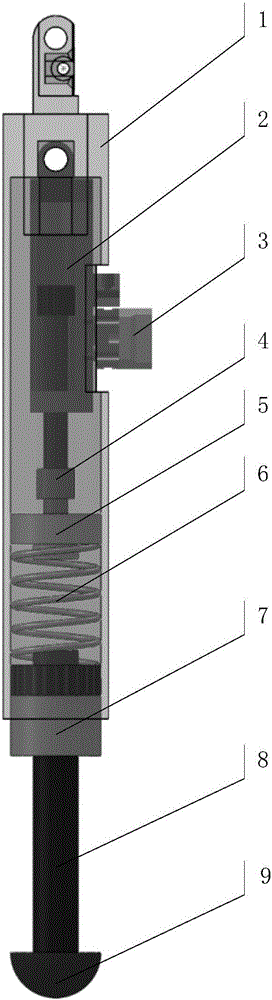

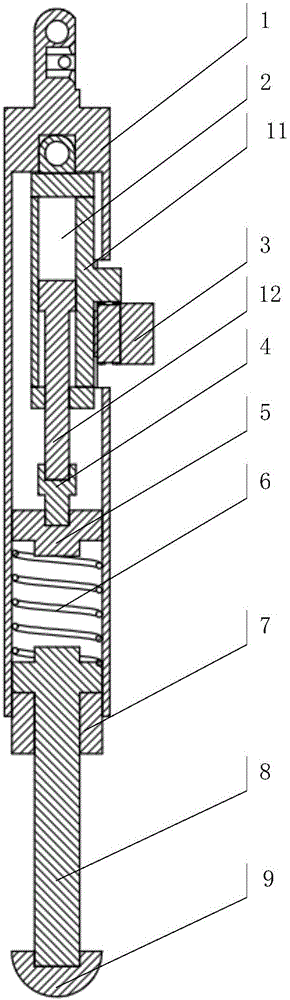

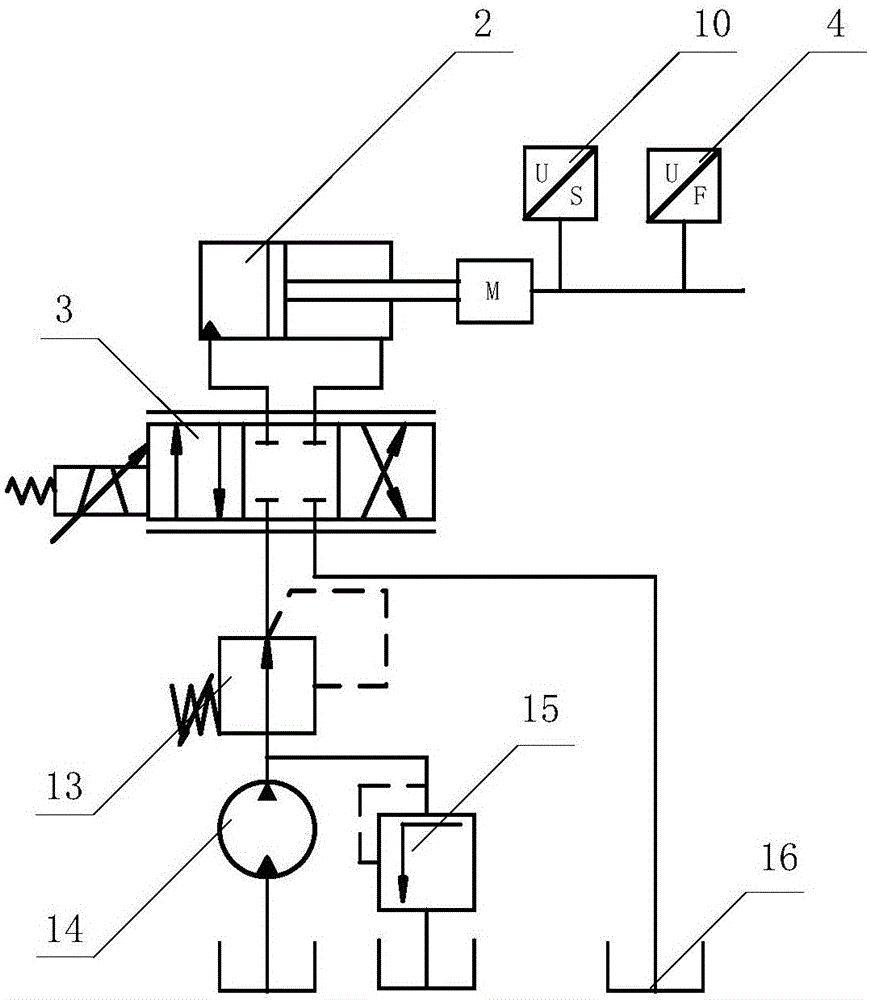

[0031] A hydraulic robot active and compliant foot mechanism, such as figure 1 and figure 2 As shown, it includes: foot sleeve 1, hydraulic cylinder 2, servo valve 3, force sensor 4, slider 5, spring 6, pre-tightening screw 7, foot end rod 8, foot end hemisphere 9, displacement sensor 10; Described hydraulic cylinder 2 is made up of hydraulic cylinder barrel 11 and hydraulic cylinder rod 12;

[0032] Also includes pressure reducing valve 13, hydraulic pump 14, overflow valve 15, oil tank 16;

[0033] The foot sleeve 1 is a hollow sleeve with an open bottom, with a raised platform on the top, and a pin hole on the raised platform for connecting with the leg joints of the robot. The wall of the foot sleeve 1 is provided with an opening. The opening corresponds to the hydraulic cylinder 2; the hydraulic cylinder 2 is placed inside the foot sleeve 1, and the cylinder barrel 11 of the hydraulic cylinder is fixedly connected to the foot sleeve 1; the displacement sensor 10 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com