A storage device for reducing volatilization and odor of mixed aromatics

A mixed aromatics and storage technology, applied in the field of chemical storage, can solve the problems of increasing operating costs of enterprises, large nitrogen usage, environmental pollution, etc., and achieves the effects of simple structural modification, environmental improvement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

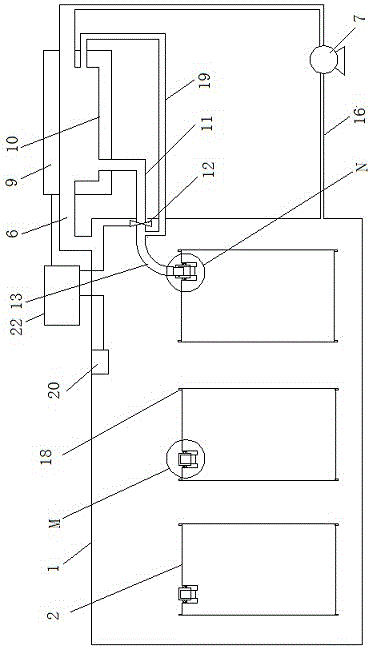

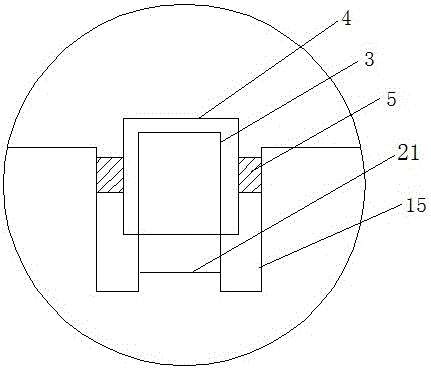

[0029] Such as figure 1 , 3 A storage device for reducing volatilization and odor of mixed aromatics shown in , 4 and 5, comprising a storage warehouse 1 and a storage tank, the storage warehouse 1 is provided with a detection device 20; the storage tank is placed in the storage warehouse 1; The storage tank includes a tank body 2, a tank mouth 3 and a tank cover 4, the inner lower end of the tank mouth 3 is provided with a valve 21, and the periphery of the tank mouth 3 is provided with a circle of grooves 5, and the groove 5 extends into the Inside the tank body 2, the tank cover 4 is screwed on the tank mouth 3 and penetrates into the groove 5; the inside of the storage warehouse 1 is filled with nitrogen, and the top is provided with a nitrogen discharge pipe 6, and the end of the nitrogen discharge pipe 6 passes through The fan 7 is connected to the nitrogen return pipeline 16, and the nitrogen return pipeline 16 is connected to the bottom of the warehouse 1; the middle ...

Embodiment 2

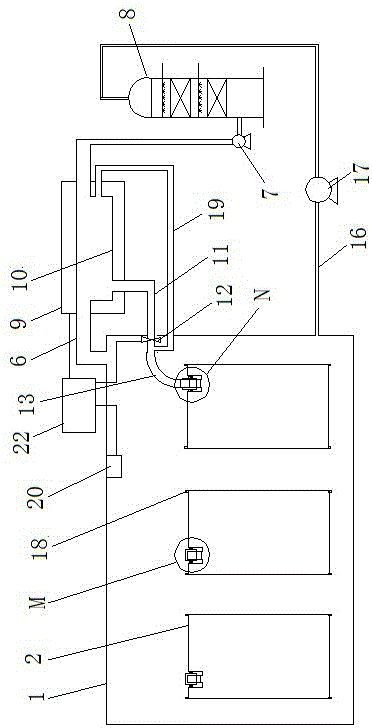

[0031] Such as Figure 2-5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the fan 7 is connected to the nitrogen return pipeline 16 through the absorption and adsorption device 8, and the nitrogen return pipeline 16 is connected to the bottom of the storage warehouse 1 through the induced draft fan 17, and the absorption and adsorption device 8 Packed adsorption tower. The tank mouth 3 is 20.5cm higher than the tank body, and the upper and lower ends of the tank body 2 are provided with flanges 18 on the outer wall. The height of the flanges 18 is 1 cm, and is greater than the height of the tank mouth 3. The tank body 2 is stacked, but the sealing effect of the tank mouth 3 is not affected.

Embodiment 3

[0033] Such as Figure 2-5As shown, a storage device for reducing the volatilization and odor of mixed aromatic hydrocarbons is shown, including a storage warehouse 1 and a storage tank, the storage warehouse 1 is provided with a detection device 20; the storage tank is placed in the storage warehouse 1; The storage tank includes a tank body 2, a tank mouth 3 and a tank cover 4, the inner lower end of the tank mouth 3 is provided with a valve 21, and the periphery of the tank mouth 3 is provided with a circle of grooves 5, and the groove 5 extends into the tank. Inside the body 2, the tank cover 4 is screwed on the tank mouth 3 and penetrates into the groove 5; the inside of the storage warehouse 1 is filled with nitrogen, and the top is provided with a nitrogen discharge pipe 6, and the end of the nitrogen discharge pipe 6 is passed by a fan 7 is connected to the absorption and adsorption device 8, and the middle part of the nitrogen discharge pipeline 6 is also covered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com