Logistic tower equipment

A logistics tower and equipment technology, which is applied in the field of warehousing and logistics, can solve the problems of low positioning accuracy of manipulators and pallets, low shelf space utilization, and long operating takt time, so as to save takt time, high space utilization, and shorten takt time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

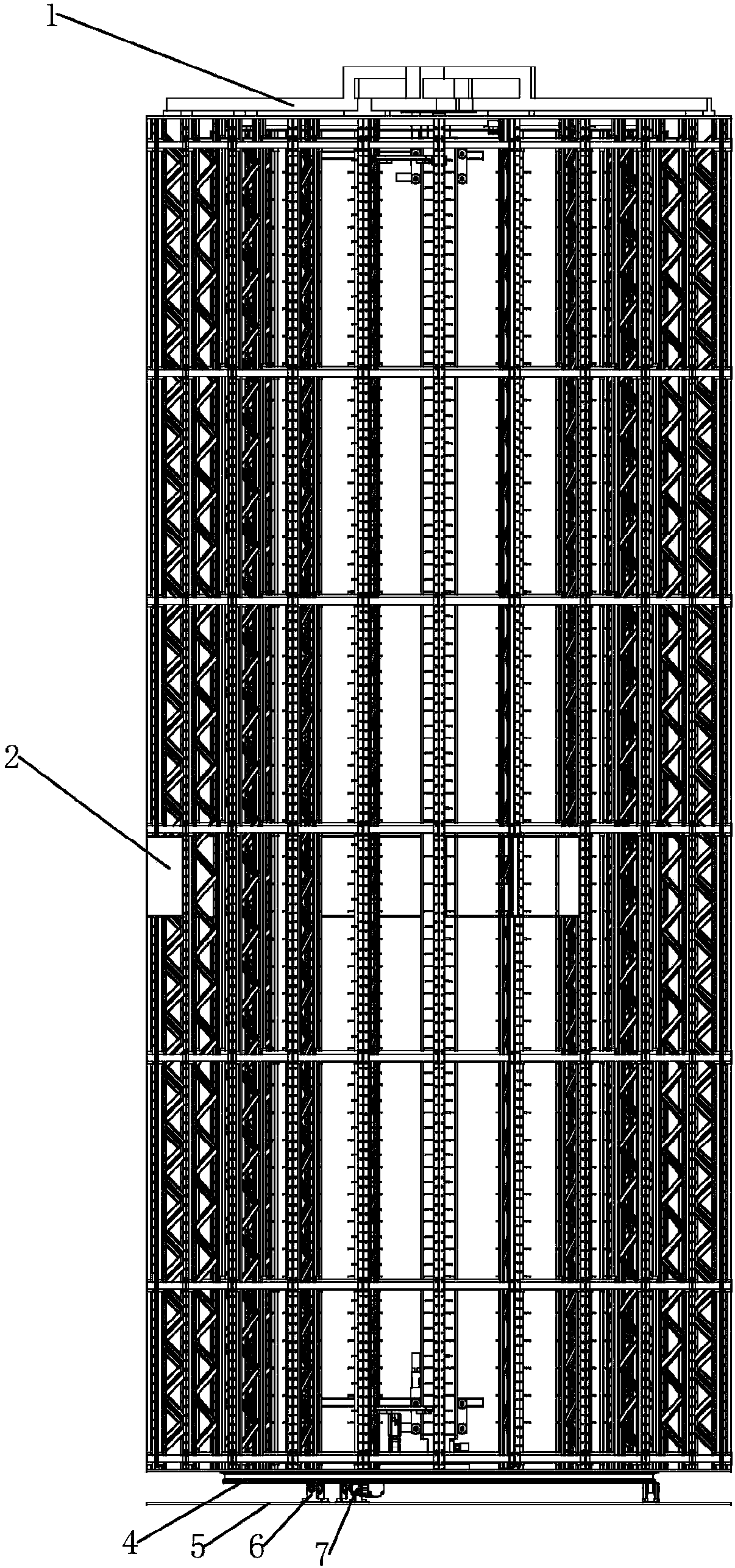

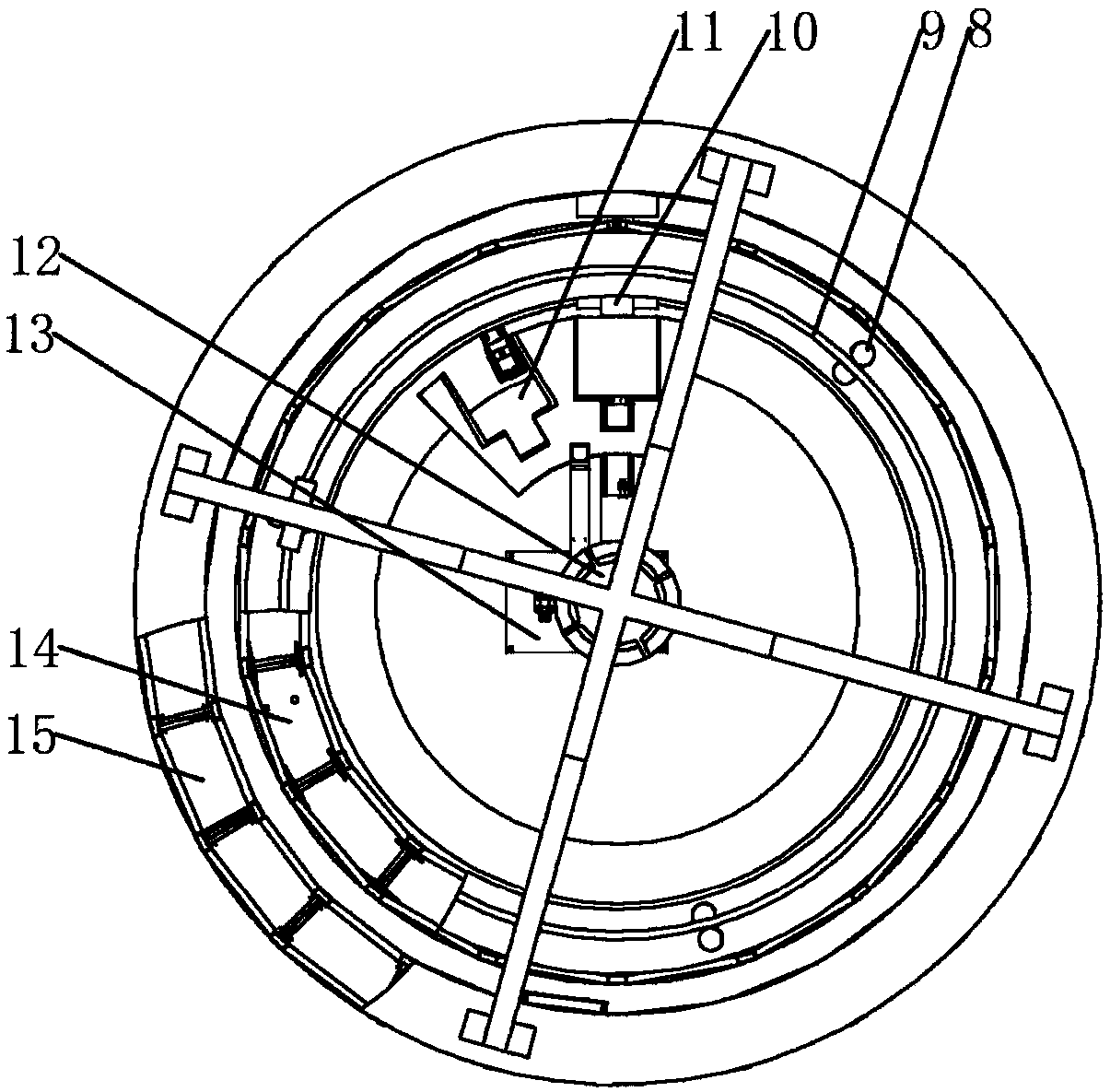

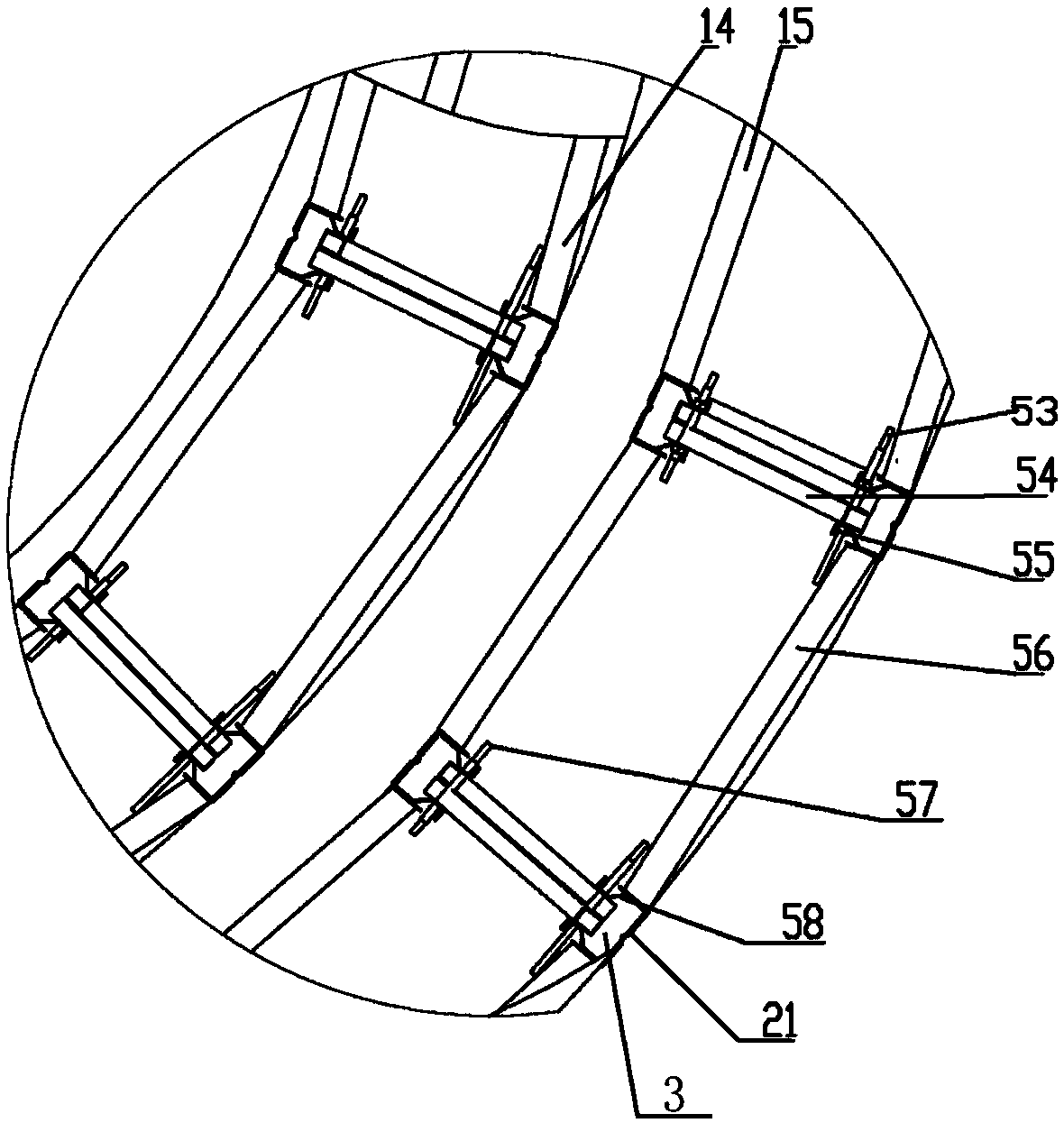

[0034] Example: such as Figure 1-Figure 2 As shown, the present invention includes an adjustment frame 1, a window 2, an outer shelf, an inner shelf, a central rotating column 32, a sky rail assembly, a ground rail assembly, a vertical drive device, a buffer mechanism and a manipulator assembly. The adjustment frame 1 Placed on the top of the outer shelf and the inner shelf, respectively connected to the outer shelf, inner shelf, and central revolving column 32, the inner shelf is placed in the outer shelf, and the inner shelf is connected to the adjustment frame 1 through the sky rail assembly , is connected to the ground through the ground rail assembly, and performs circular rotation along the sky rail 9 and the ground rail 4. The central rotary column 32 is installed in the middle of the inner shelf, and the buffer mechanism and the manipulator assembly are installed on the central rotary column 32 through a vertical drive device. Up and down, move up and down along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com