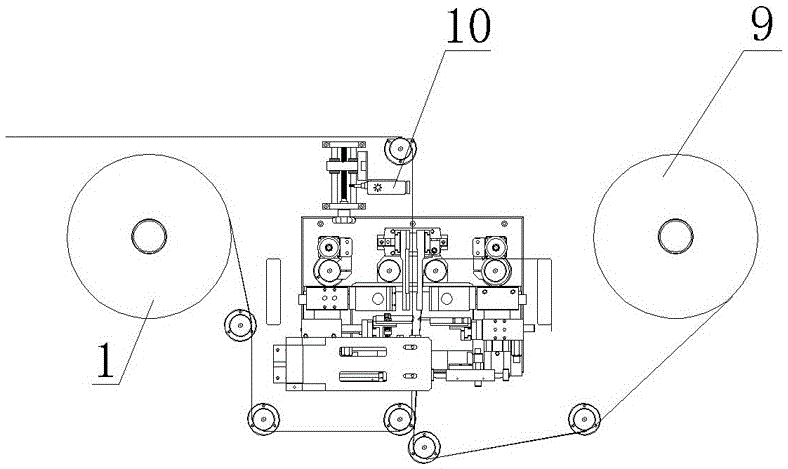

Automatic color code-alignment film bonding mechanism for packaging machine

A packaging machine and color code technology, which is applied in transportation and packaging, winding strips, thin material processing, etc., can solve the problems of time-consuming and laborious, can only be discarded, and packaging film is difficult to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

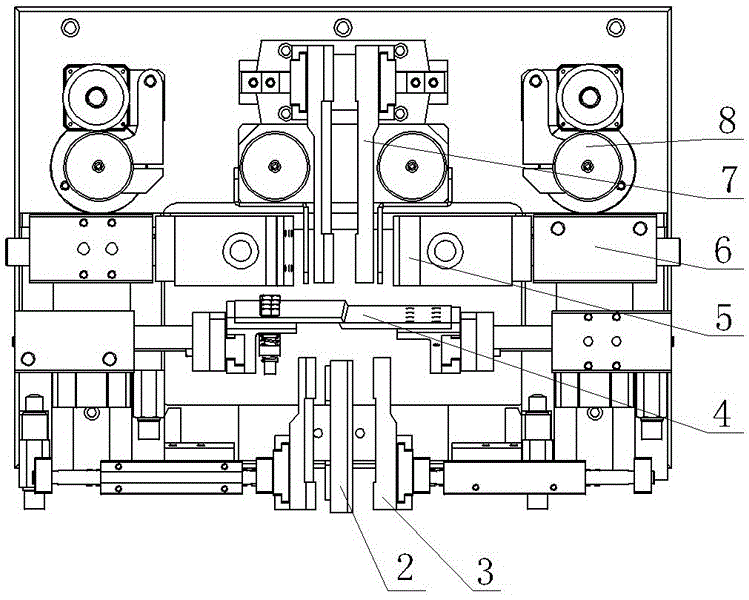

[0012] As shown in the figure, the automatic color-marking film splicing mechanism of the packaging machine includes the left coil roll 1, the right coil roll 10 and the middle plate 2. There is an openable cutter group 4 above the plate 2, and an openable tape vacuum suction box group 5 is provided above the cutter group 4. The cutter group 3 and the tape vacuum suction box group 4 are connected to the lifting seat 6, and the tape vacuum The suction box group 4 is connected to the lifting seat 6 through the slide rail, which is convenient to pull out the tape vacuum suction box group 4 and put the tape on it. There is also an openable upper clamping plate group 7 above the cutter group 4. The left and right sides of the tightening plate group 4 are respectively provided with rejecting wheel groups 7 , and the top of the upper clamping plate group 4 is also provided with a color-coded light eye 10 .

[0013] The working principle of the present invention is: when the left coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com