Continuous dispersion device used for lithium-ion battery slurry

A technology of lithium ion battery and dispersing device, applied in transportation and packaging, mixer, mixing method, etc., can solve problems such as poor dispersion effect, and achieve the effect of improving dispersion quality and production efficiency, and improving dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

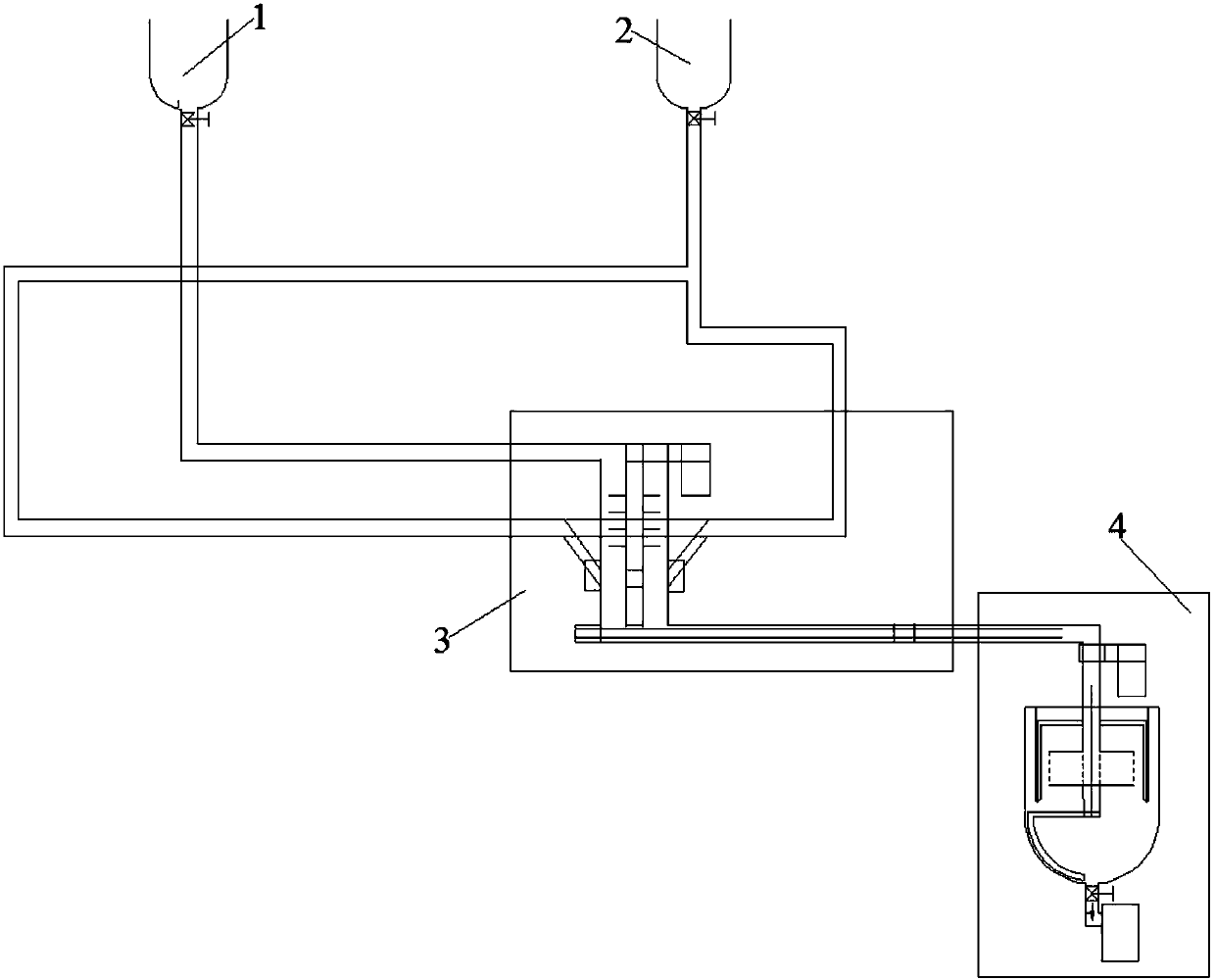

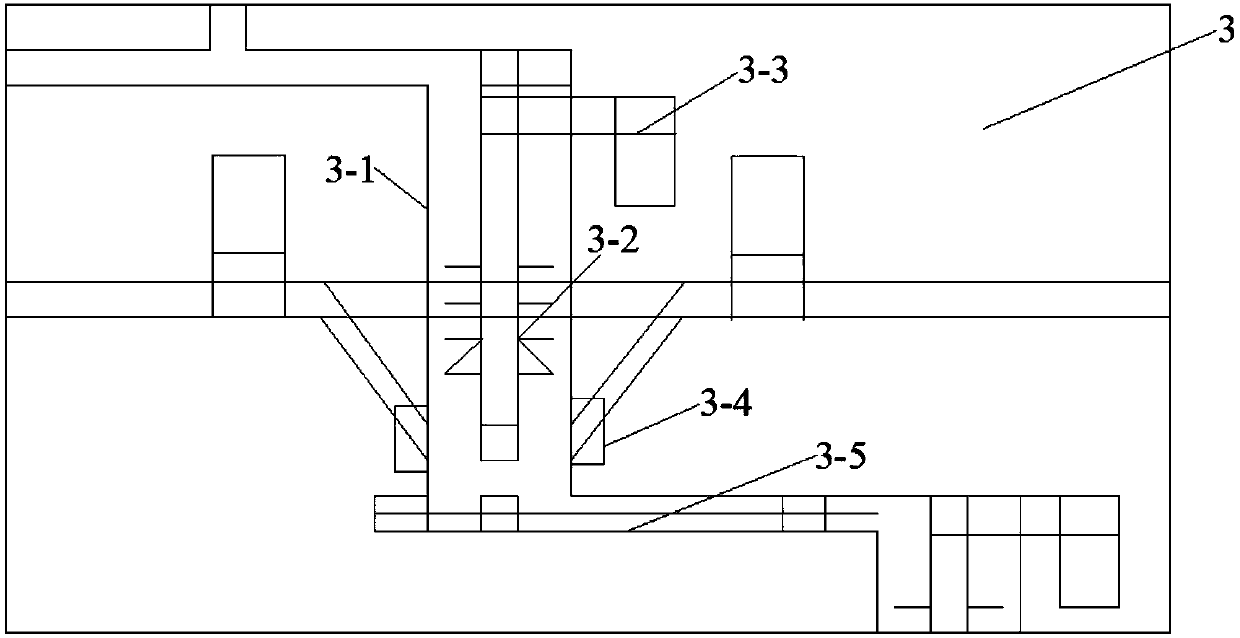

[0024] Such as figure 1 As shown, the present invention is used for the continuous dispersing device of lithium-ion battery slurry, and it comprises at least one powder material storage tank 1, at least one solvent storage tank 2, primary primary dispersing mechanism 3 and primary centrifugal dispersing mechanism 4, each The bottom discharge port of each powder material storage tank 1 and the bottom discharge port of each solvent storage tank 2 are all connected with the primary dispersion mechanism 3 through pipelines, and the discharge port of the primary dispersion mechanism 3 is connected with the centrifugal dispersion mechanism 4; The powder material in each powder material storage tank 1 and the liquid material in each solvent storage tank 2 first enter the primary dispersion mechanism 3 for primary dispersion, and then enter the centrifugal dispersion mechanism 4 for centrifugal dispersion. Preferably, a meter is provided on the pipeline leading to the primary dispersi...

Embodiment 2

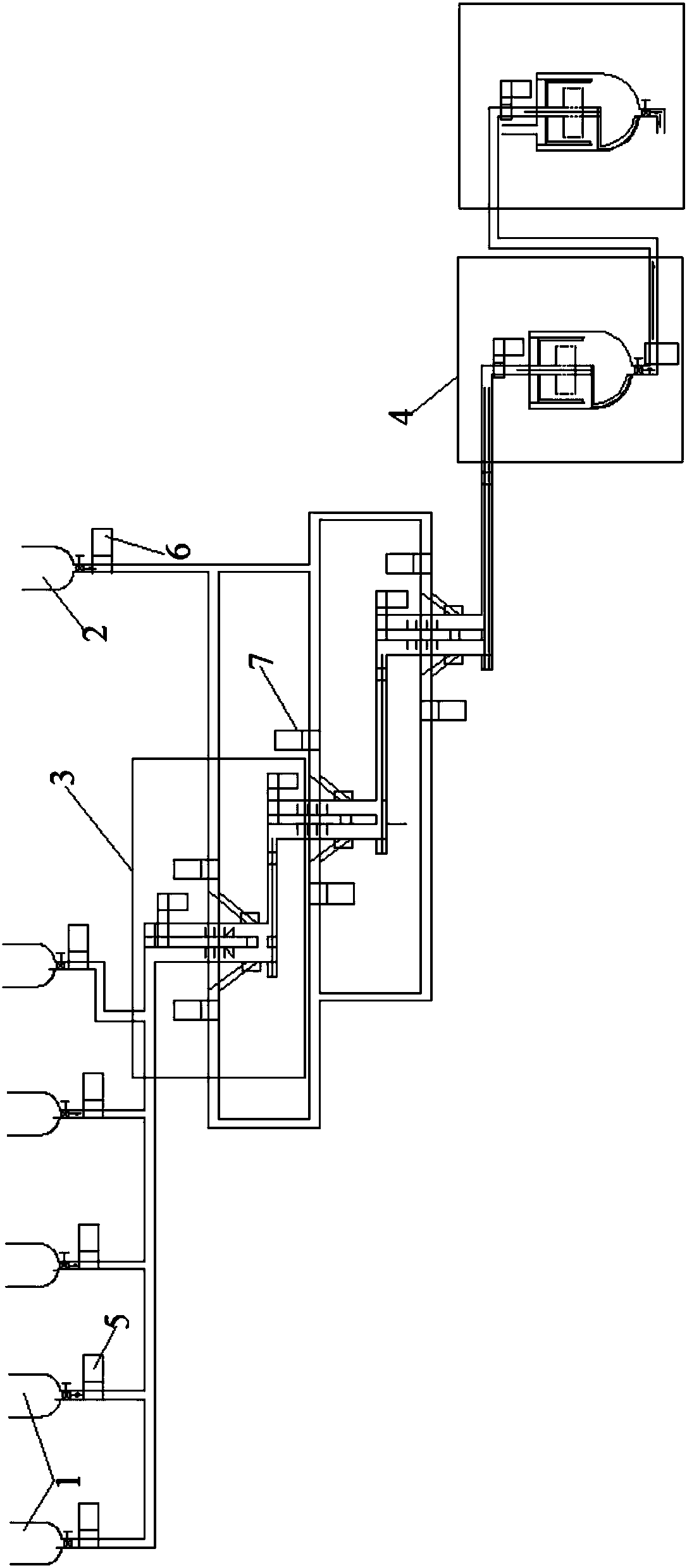

[0027] Such as image 3 Shown is a preferred embodiment of the present invention, wherein, the primary dispersion mechanism 3 is provided with three stages: wherein the upper end feeding port of the primary dispersion tank body 31 in the primary dispersion mechanism 3 of the first stage is connected with each powder material storage tank 1 The outlets at the bottom of the bottoms are all communicated through pipelines, and on the pipeline from each powder material storage tank 1 to the primary dispersion tank body 31 in the first-stage primary dispersion mechanism 3, there are devices for measuring the total amount of each powder material. The first level meter 5 of the amount; the discharge port of the screw extruder 35 in the primary dispersing mechanism 3 of the first stage is communicated with the upper end feeding port of the primary dispersing tank body 31 in the primary dispersing mechanism 3 of the second stage; The discharge port of the screw extruder 35 in the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com