A kind of silicon wool product and preparation method thereof

A technology of silicon wool and products, which is applied in the field of daily consumer goods manufacturing, can solve the problems of failure to form elastic silicone layer, deformation, and non-crosslinking of silicone treatment agents, etc., and achieve the effect of long-term compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

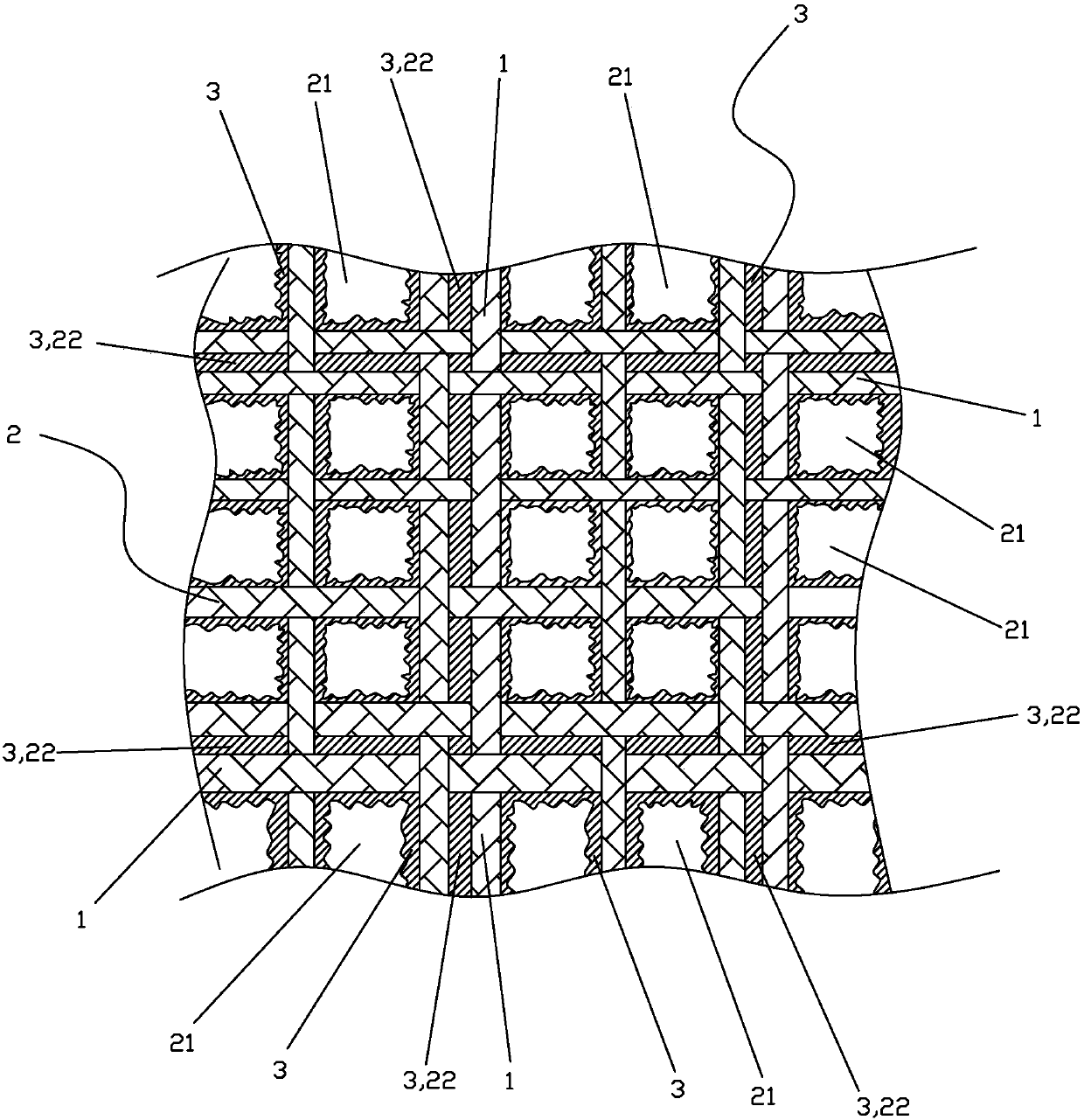

Image

Examples

Embodiment 1

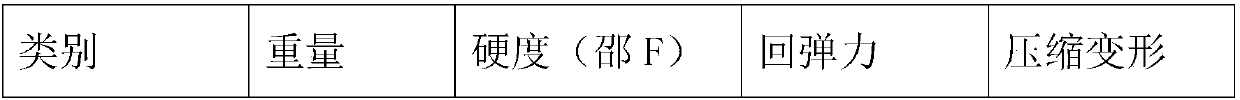

[0037] a. The density of compressed chemical fiber is 6kg / m 3 , A chemical fiber board with a thickness of 6cm and a resilience of 8%, cut the chemical fiber board to a suitable size, put it into a pillow mold at a temperature of 190℃, press it with a plate vulcanizer for 5 minutes, take it out and cool it, and shape it into a pillow shape. (No. 1 pillow)

[0038] b. Immerse the shaped No. 1 pillow in a silica gel solution with an operating viscosity of 20mPa.S (the hardness of silica gel is Shore A: 20 degrees), take it out after 1 minute, let it sit for 5 minutes, let the excess solution flow out, and use it again The calendering roller crushes the pillow to discharge the excess organic silicon solution, and adjusts the remaining amount of the silica gel solution by adjusting the rolling pressure.

[0039] c. Put the treated pillows in the oven and bake them at 120°C for 30 minutes. (No. 2 pillow)

[0040] During the experiment, the performance test was performed on the No. 1 pi...

Embodiment 2

[0045] The preparation conditions and parameters of Example 2 are the same as those of Example 1. The hardness of the addition type liquid silica gel is selected to be Shore A: 50 degrees. The test method is also the same as that of Example 1. The results are shown in Table 2:

[0046] Table 2:

[0047] category

Embodiment 3

[0049] The preparation conditions and parameters of Example 3 are the same as those of Example 1. The hardness of the addition type liquid silica gel is selected to be Shore A: 70 degrees. The test method is also the same as that of Example 1. The results are shown in Table 3:

[0050] table 3:

[0051] category

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com