Construction method of a retaining wall structure composed of waste tires and broken concrete

A technology for crushing concrete and waste tires, which is applied in infrastructure engineering, underwater structures, artificial islands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

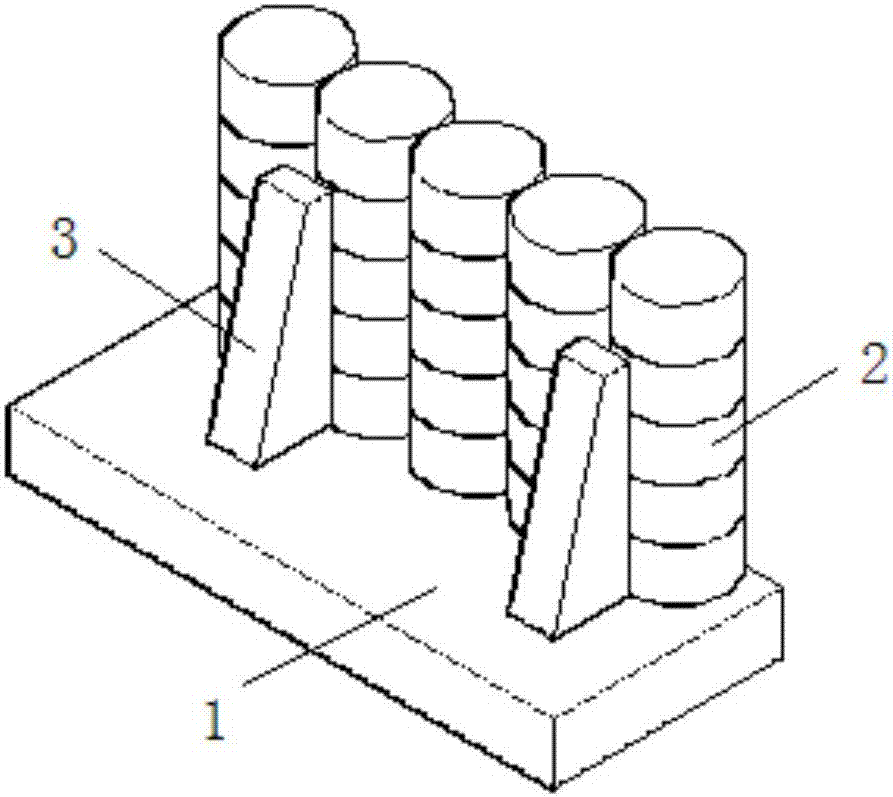

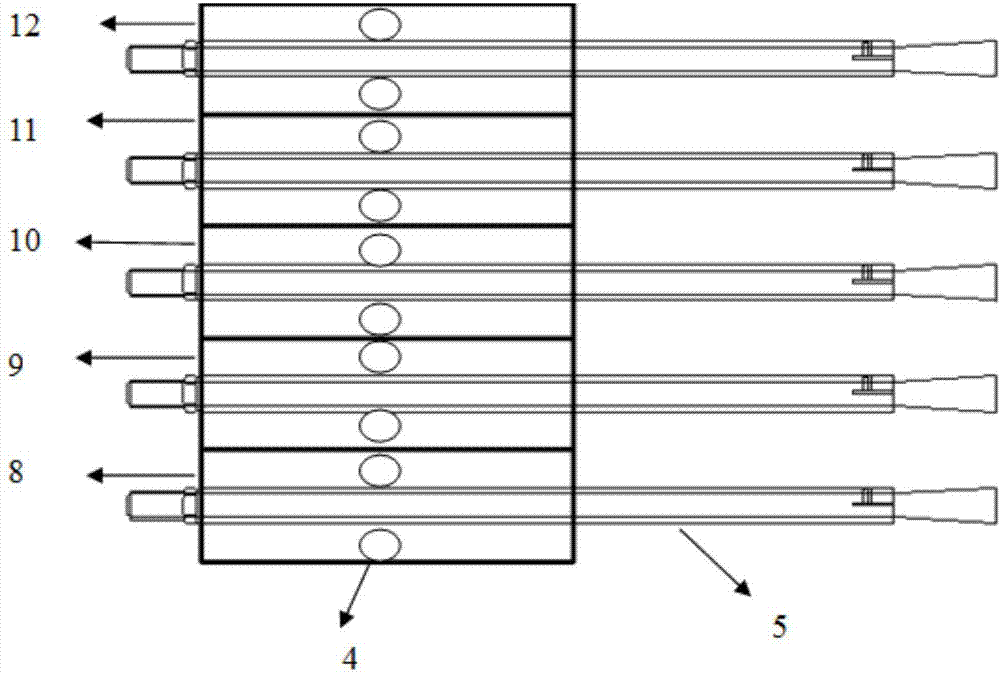

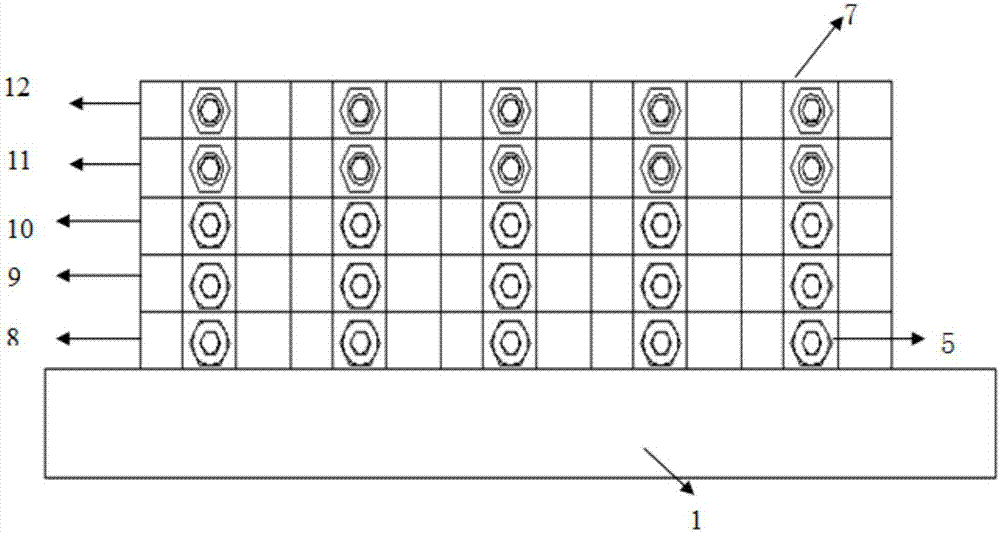

[0073] The tire gabion retaining wall of the present invention has a length of 4m, and a single-stage retaining wall has a height of 3m. The size of the base is 4*1.5*0.5m. The tire uses: 215 / 70R15 tires, that is, the tire inner diameter is 70% in inches and the tire width is 215mm. Install it on the base, and use high-strength bolts to connect the tire along the wall with grouting and drive into the horizontal connection anchor rod , Drive in the self-anchored anchor rod, assemble the second layer, the third layer, etc. Finally in the factory according to the mix ratio of cement: water: fine aggregate: coarse aggregate = 1.0: 0.32: 0.92: 2.34, pour recycled concrete into the tire Finally, the soil is backfilled, and the height of the backfill is 0.8 meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com