Staggered-type adapter used for mounting lever-type sensor on pressure vessel

A technology for pressure vessels and transition joints, which is applied to connecting components, pins, mechanical equipment, etc., can solve the problems of prolonged testing time, improper welding methods, inconvenient installation and operation, etc., to improve the sealing effect and shorten the preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

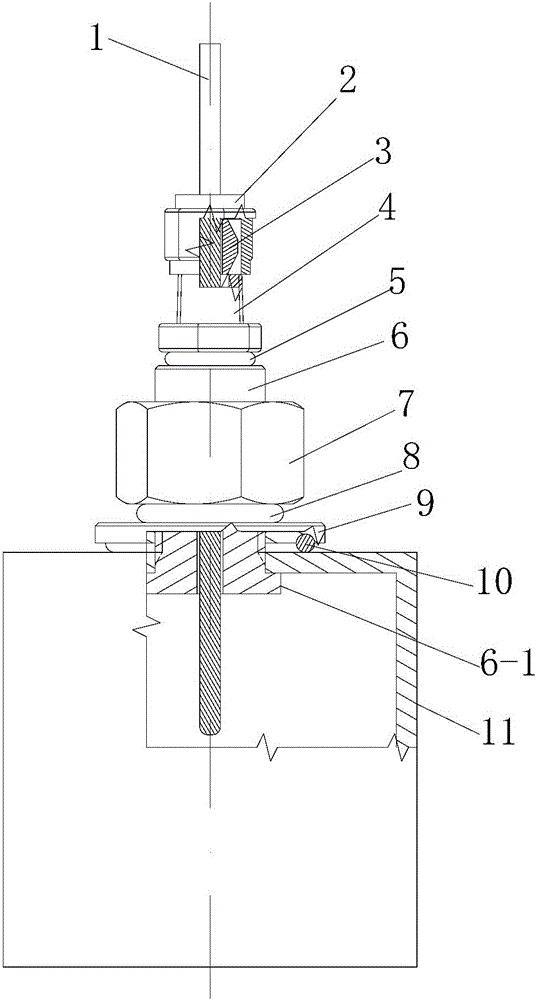

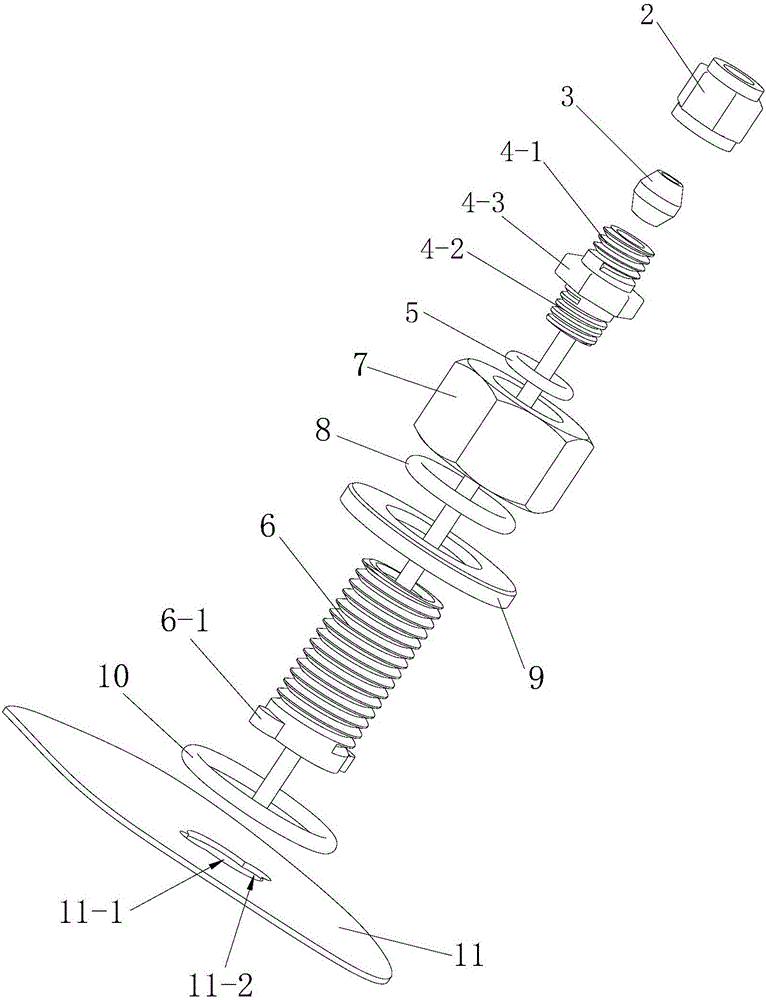

[0036] like figure 1 and figure 2 As shown, a misplaced adapter for installing a rod sensor on a pressure vessel includes a core rod 6 arranged in a test hole 11-1 of a pressure vessel 11, and the test hole 11-1 of the pressure vessel 11 There is a notch 11-2 on the hole wall, and the lower end of the core rod 6 is provided with a dislocation claw 6- that extends into the pressure vessel 11 from the notch 11-2 and closely fits the inner top wall of the pressure vessel 11 after rotation. 1. The core rod 6 is covered with a compression nut 7 for locking the position of the misaligned claw 6-1. The compression nut 7 is arranged above the pressure vessel 11, and the core rod 6 is provided with a There is a through hole for the rod sensor 1 to pass through and extend into the inside of the pressure vessel 11 .

[0037] In this embodiment, when the dislocation adapter is installed, the lower end of the core rod 6 is first inserted into the pressure vessel 11 from the test hole 11...

Embodiment 2

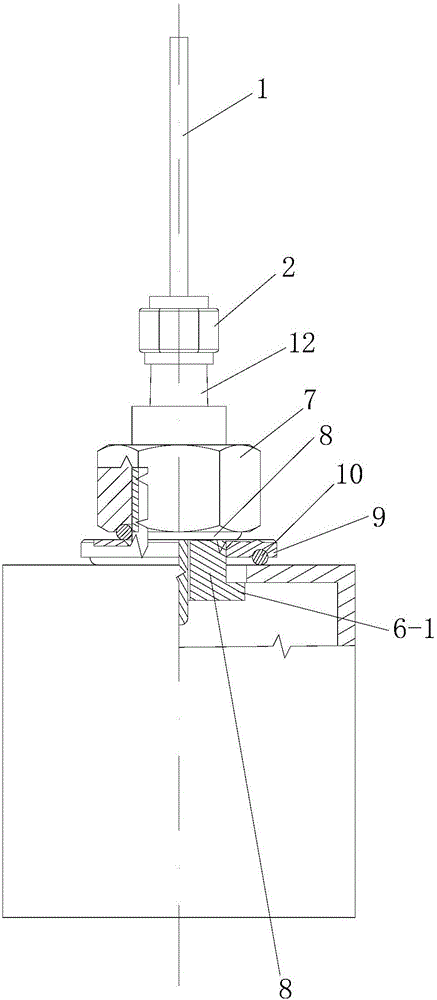

[0058] like image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the core rod 6 is connected with the pressure cap 2 through a core rod connecting rod 12, and the core rod connecting rod 12 is installed on the core rod 6 The upper end of the core rod connecting rod 12 is provided with a hole 12-1 communicating with the through hole on the core rod 6, and the outer wall of the core rod connecting rod 12 is provided with an external thread for connecting with the pressure cap 2.

[0059] In this embodiment, the quick connection between the core rod 6 and the pressure cap 2 can be realized by setting the core rod connecting rod 12. The core rod connecting rod 12 can be integrally formed on the upper end of the core rod 6, or can be Through the threaded connection between the external thread of the core rod connecting rod 12 and the internal thread of the through hole wall of the core rod 6, a hole 12-1 is set on the core rod connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com