Unscrewing non-following type angle valve

A technology of angle valve and valve body, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problem that the tank vehicle loading and unloading valve is not suitable for high-temperature and high-viscosity material loading and unloading, and achieves good sealing performance, improved use efficiency, and convenience The effect of human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

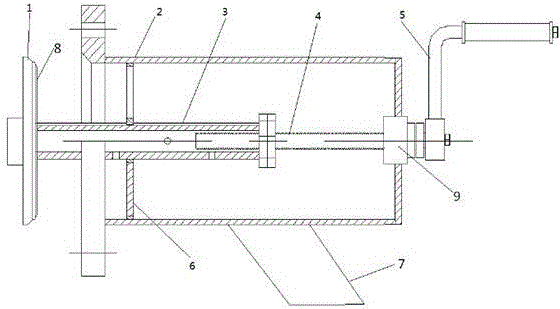

[0013] As shown in the figure, a rotary non-follow-up angle valve is mainly composed of a valve body 2, an inner valve stem 3 and a push-pull screw 4. The valve body 2 is a sleeve type structure, and the inner valve stem 3 is fixed by the valve stem. The seat 6 is fixed in the valve body 2. One end of the inner valve stem 3 is connected to the sealing valve plate 1, and the other end of the inner valve stem 3 is connected to the push-pull screw 4 to form a screw sleeve type non-follow-up opening structure, rocker 5 Pass through the screw fixing seat 9 to connect with the push-pull screw 4, a convenient unloading joint 7 is arranged at the bottom of the valve body 2, and a sealing ring 8 is arranged on the surface of the sealing valve plate 1.

[0014] The working principle of the invention: the angle valve adopts metal direct pressure seal and is inlaid with a unique sealing structure. It has the characteristics of high temperature resistance and has been opened, which avoids the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com