High-reflectance LED backlight plate

A technology of LED backlight and high reflectivity, applied in the field of electric light source, can solve the problems of low reflectivity, poor astigmatism effect, poor light output efficiency, etc., and achieve the effect of improving light output efficiency and reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

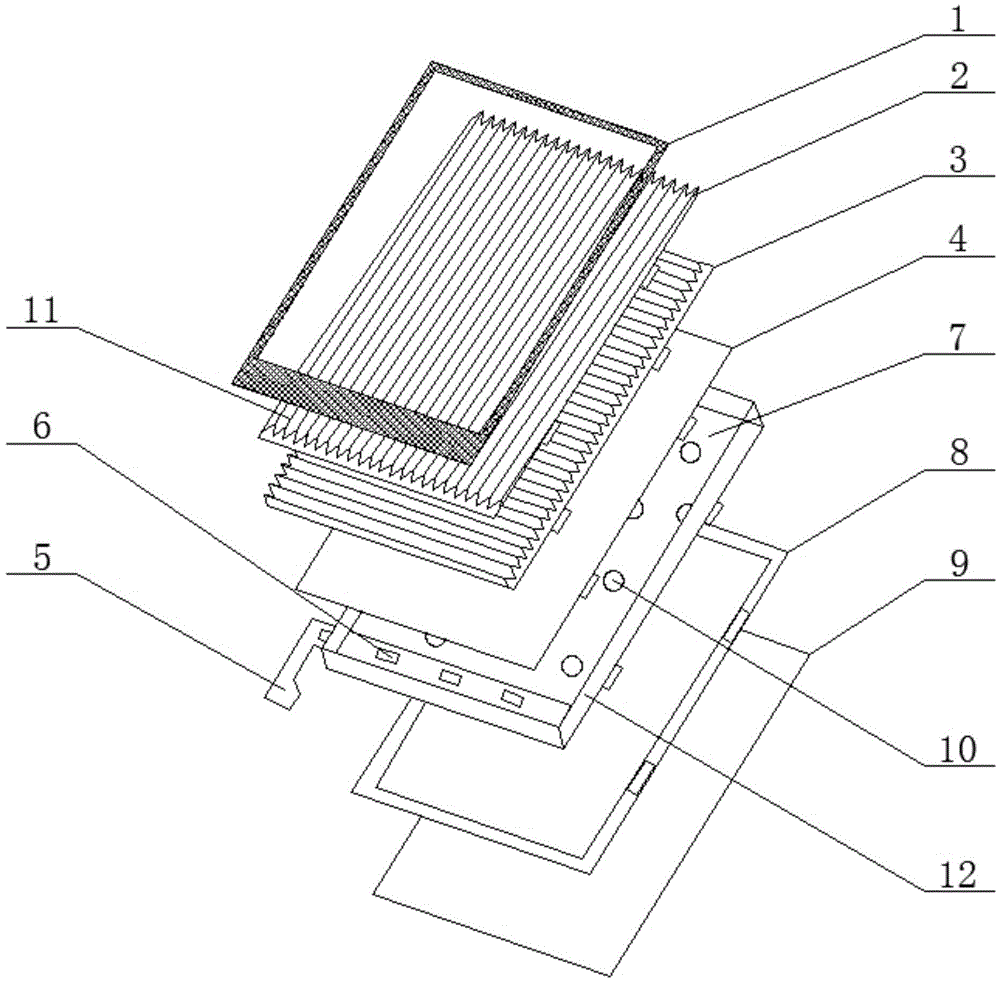

[0012] Such as figure 1 A high-reflectivity LED backlight panel as shown includes black and white double-sided adhesive tape 1, upper diamond sheet 2, lower diamond sheet 3, diffusion film 4, light guide plate 7, plastic frame 8 and reflection film 9, a flexible circuit board 5 is provided on the top of the light guide plate 7, and an LED lamp 6 is provided on the flexible circuit board 5. A number of parallel rhombic pillars 11 are respectively distributed on each rhomboid, and the directions of the rhomboid pillars 11 on the two rhomboids differ by 90°. The light guide plate 7 is completely surrounded by a white reflective frame 12 , and the light guide plate 7 is provided with bumps 10 .

[0013] The upper diamond 2, the lower diamond 3 and the diffusion film 4 are combined and directly pasted on the light guide plate 7, and then the black and white double-sided adhesive 1 is covered on the uppermost layer, stuck on the plastic frame 8, and pressed tightly. The black and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com