Camera module

A camera module and lens module technology, applied in installation, optics, instruments, etc., can solve the problems of large thickness, large size and high cost of driving motors of handheld devices, and achieve the effect of cost saving and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

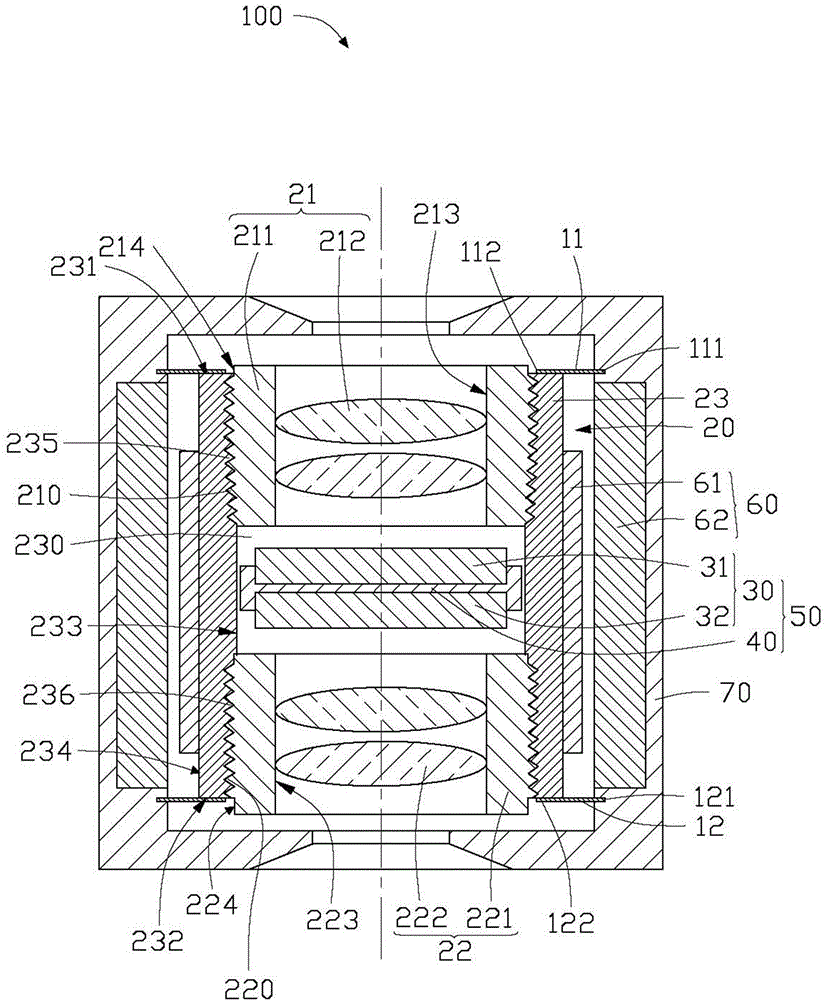

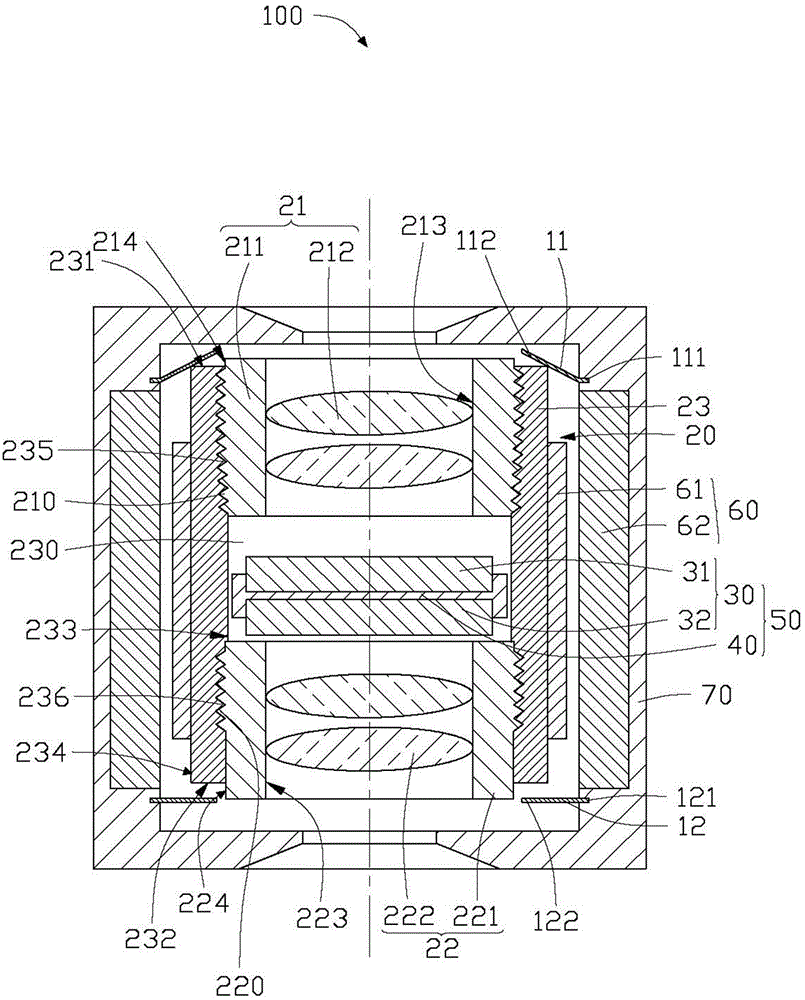

[0013] see Figure 1~2 , the embodiment of the present invention provides a camera module 100 , which includes a first elastic piece 11 , a second elastic piece 12 , a lens module 20 , an imaging unit 50 , a driving motor 60 and a housing 70 .

[0014] The lens module 20 includes a first lens module 21, a second lens module 22 and a lens mount 23, the first lens module 21 and the second lens module 22 are respectively fixed on the lens mount 23 opposite ends of the .

[0015] The lens holder 23 includes an accommodating cavity 230 , the driving motor 60 , the first lens module 21 , the second lens module 22 , and the imaging unit 50 are accommodated in the accommodating cavity 230 . The lens holder 23 includes an inner surface 233, an outer surface 234, a first end surface 231 and a second end surface 232 connecting the inner surface 233 and the outer surface 234, and the inner surface 233 is provided with a first internal thread 235 and a second internal thread. Thread 236....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com