Motor Punching Stacking Device

A motor punching and column technology, which is applied to the field of motor punching stacking devices, can solve the problems of increasing production cost, the position of riveting holes or welding holes is disordered, affecting production efficiency, etc., and achieves the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

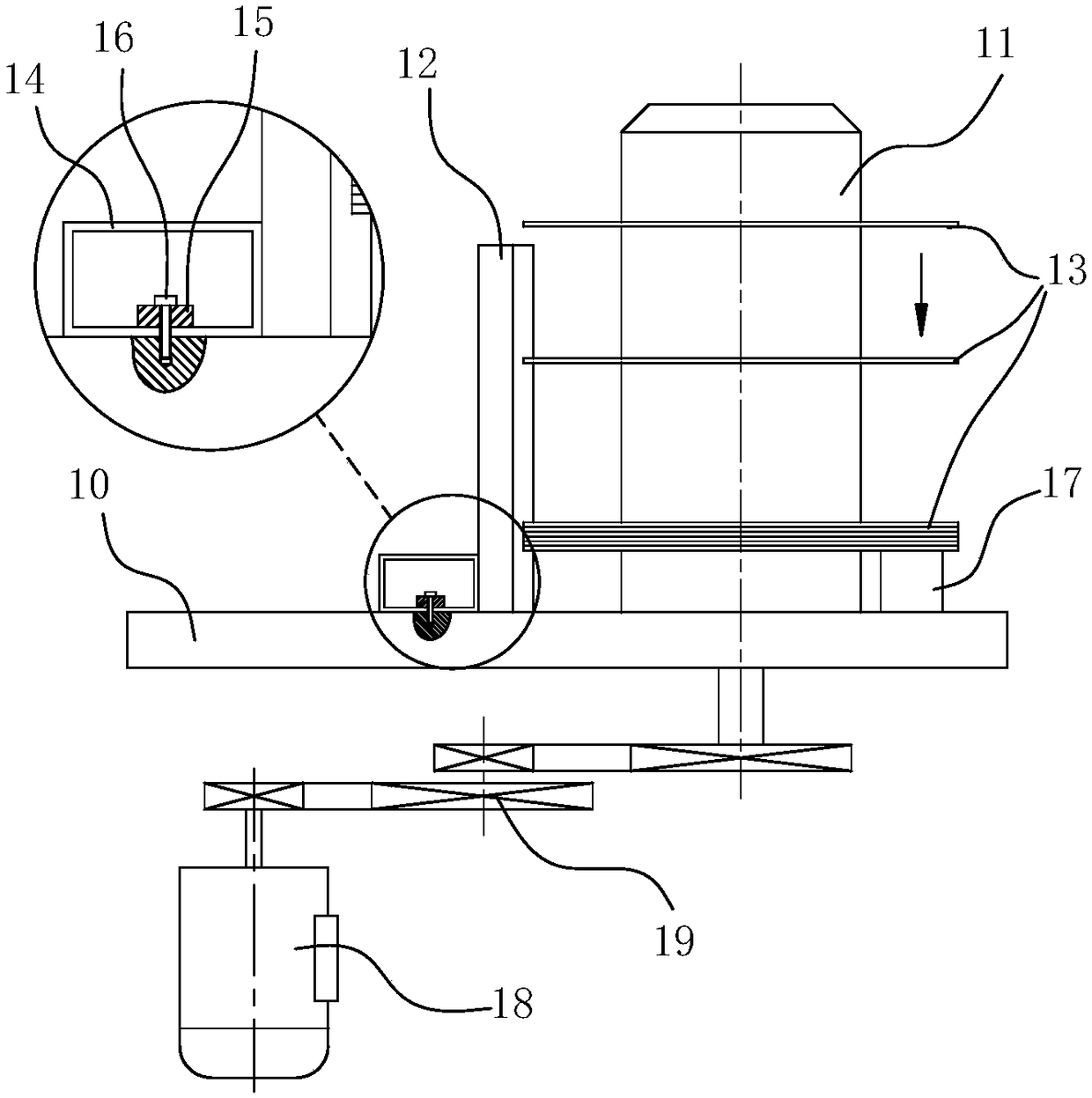

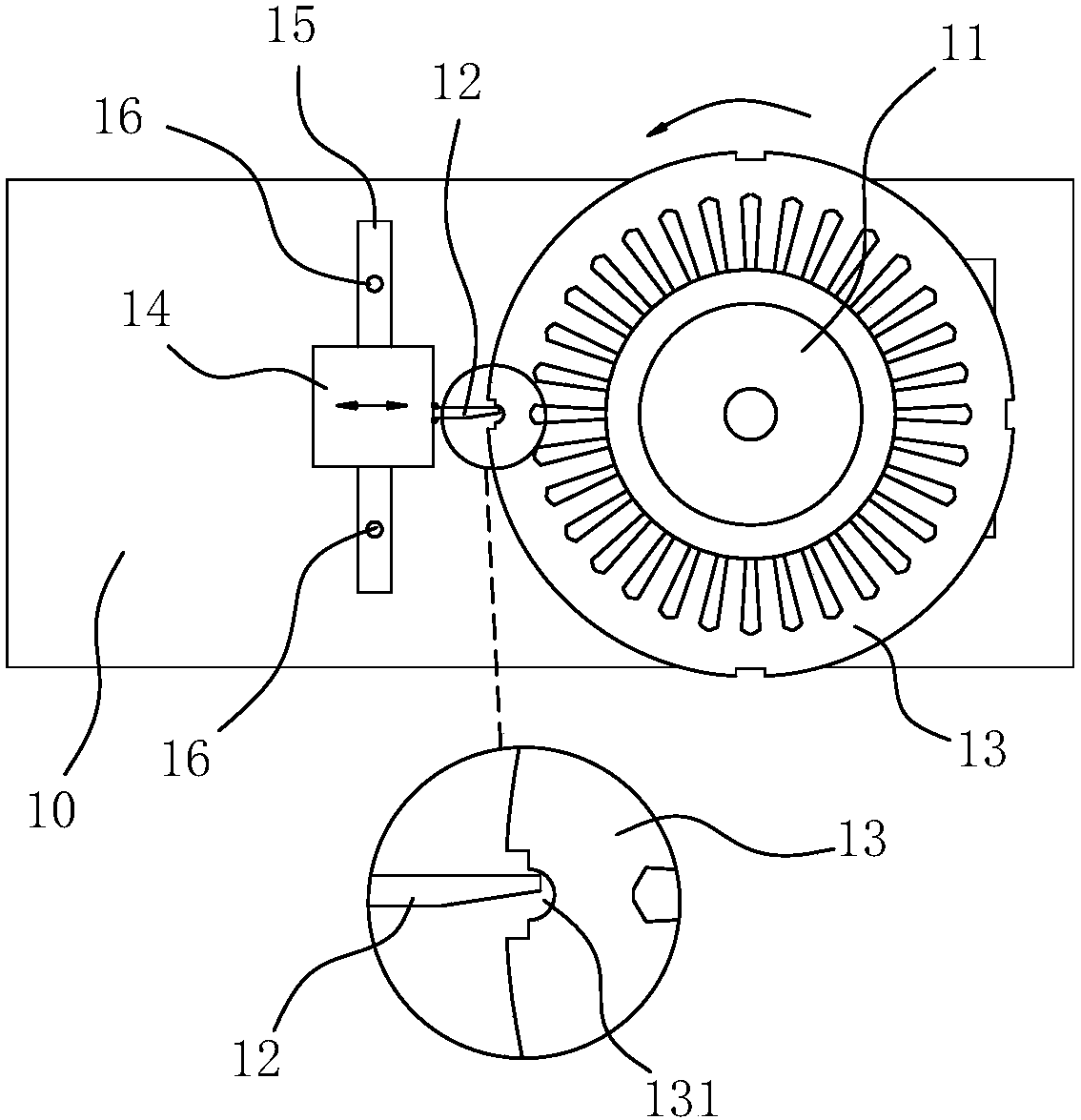

[0015] like figure 1 , 2 As shown, a motor punching stacking device includes a column 11 and a blocking piece 12 arranged on the base 10, the column 11 is rotatably arranged, and the blocking piece 12 is elongated and vertically arranged beside the column 11. The height of the top of the sheet 12 is lower than the height of the top of the column 11; when the motor punch 13 is sleeved on the column 11, the friction between the column 11 and the motor punch 13 can make the motor punch 13 rotate with the column 11, and the motor The punching piece 13 can fall by its own gravity; the distance from the blocking piece 12 to the center of the column 11 is smaller than the outer diameter of the motor punching piece 13, and the motor punching piece 13 will stop falling when it falls to the top of the blocking piece 12; the motor punching piece There is a gap 131 on the upper edge of 13. When the gap 131 is rotated to be opposite to the blocking piece 12, the motor punching piece 13 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com