A photovoltaic panel processing device based on 5g Beidou and Internet of Things positioning system

A technology of positioning system and processing device, which can be used in devices that apply liquid to the surface, photovoltaic power generation, sustainable manufacturing/processing, etc. The problem is to reduce the overflow of hot melt adhesive, reduce the structural stability, and facilitate the glue drying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

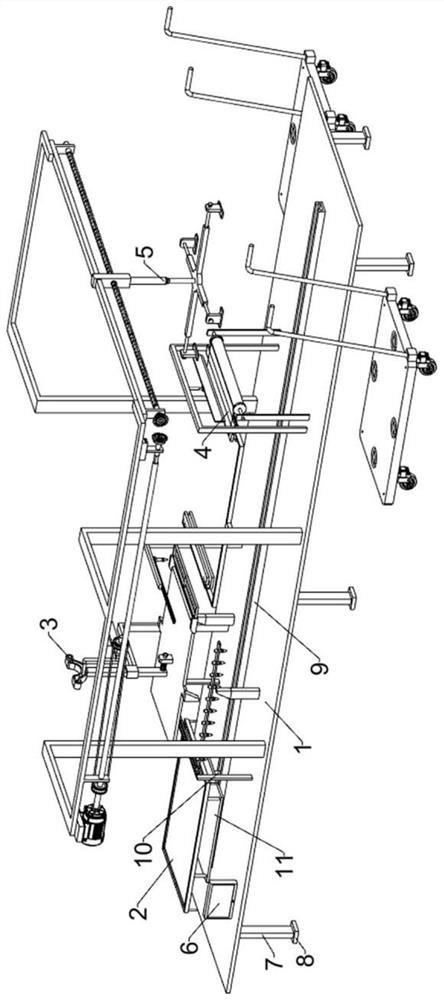

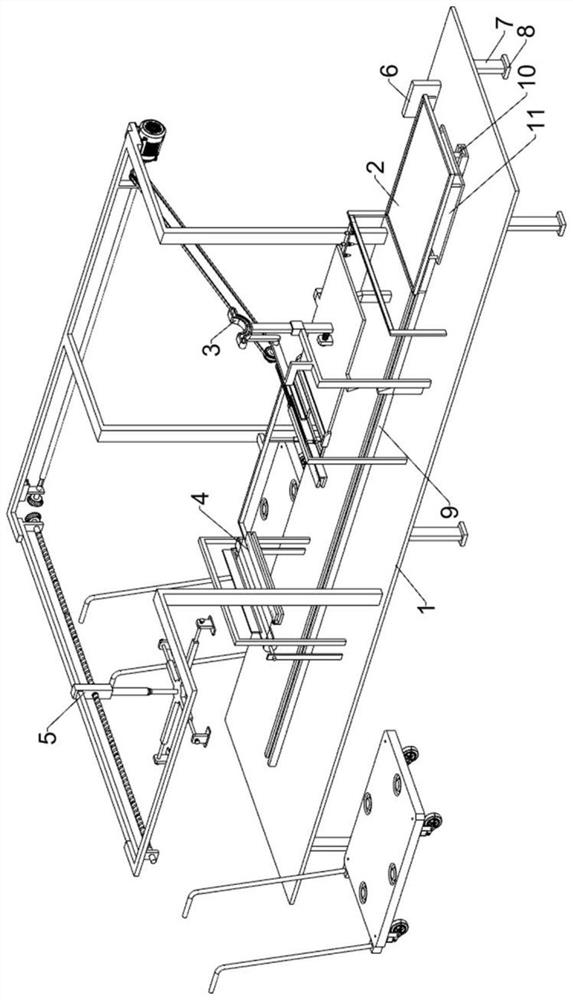

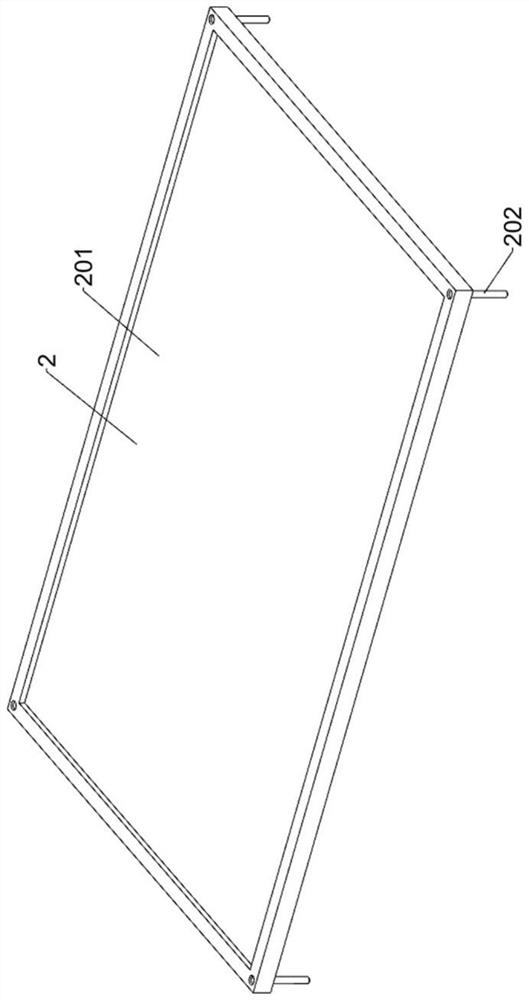

[0032] A photovoltaic panel processing device based on 5G Beidou and Internet of Things positioning system, such as Figure 1-12 As shown, it includes an underframe 1, a receiving component 2, a gluing component 3, a film component 4, a blanking component 5, a control panel 6, a first support rod 7, a first anti-skid pad 8, a first electric slide rail 9, The first slider 10 and the first support plate 11; the bottom frame 1 is connected with the gluing assembly 3; the bottom frame 1 is connected with the film assembly 4; the bottom frame 1 is connected with the blanking assembly 5; the bottom frame 1 is connected with the control panel 6 for fixed connection; base frame 1 and six groups of first support rods 7 for fixed connection; base frame 1 and first electric slide rail 9 for fixed connection; a first support plate 11 is provided under the receiving component 2; the first support plate The bottom of 11 is fixedly connected with the first slider 10; the first slider 10 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com