Stepped hole machining device with automatic waste slag collecting function

A processing device and automatic collection technology, which is applied to metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as poor working environment, difficulty in cleaning waste residue, and random falling of waste residue, achieving low labor intensity and increased cleaning Difficulty, the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] The traditional machining method of stepped holes is to use a boring machine to process the inner wall of the stepped hole, but due to the troublesome positioning of the center of the boring machine and the stepped hole, the processing efficiency of the stepped hole is low, and the processing amount is about 7-8 per day. Therefore, in order to improve the stepped hole processing efficiency, the present embodiment proposes a new step hole processing device, which includes a processing device body,

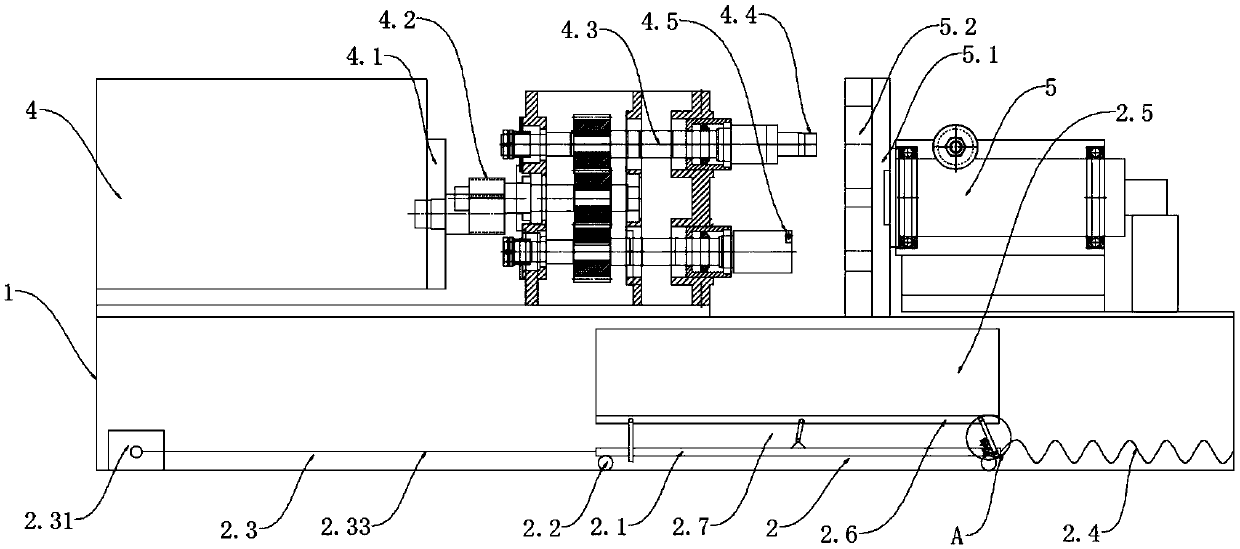

[0025] The processing device body includes a step hole processing main body 4 and a workpiece fixing device 5 which are arranged oppositely. The step hole processing main body 4 includes a power box 4.1, and a transfer case 4.2 is hinged on the power case 4.1. Inside the transfer case 4.2 There are four synchronously rotating rotating shafts 4.3, the upper two rotating shafts 4.3 are equipped with stepped hole fine boring tools 4.4, and the lower two rotating shafts 4.3 are eq...

Embodiment 1

[0028] Such as Figure 1-4 As shown, a stepped hole processing device with the function of automatically collecting waste slag includes a processing device body, which is fixed on the ground through a fixing seat 1,

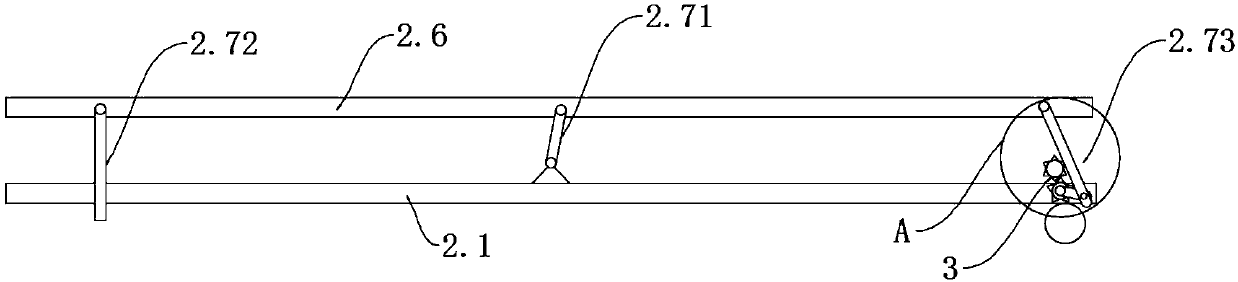

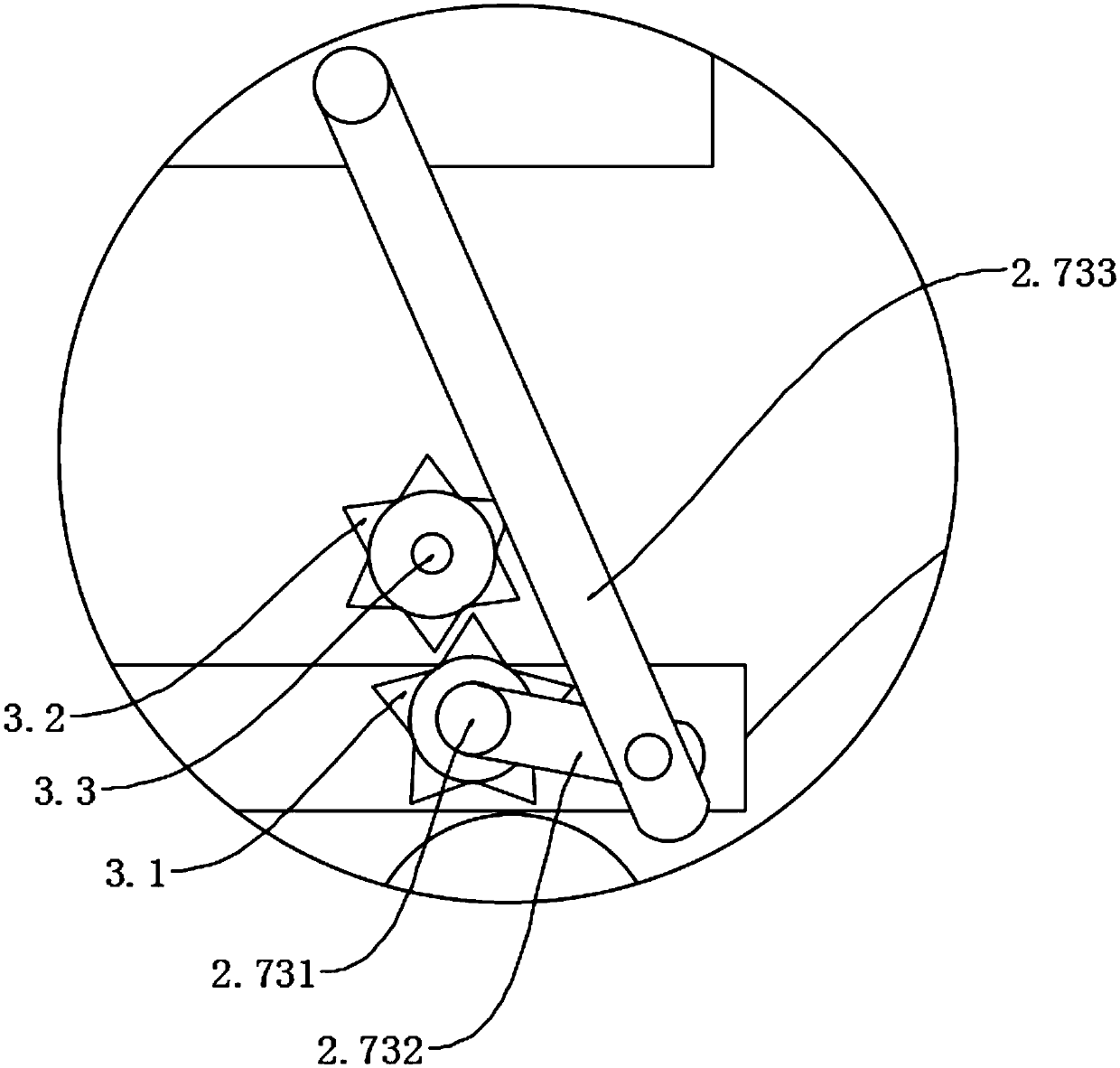

[0029] The fixed base 1 is provided with an automatic waste residue collection assembly 2, the automatic waste residue collection assembly 2 includes a moving plate 2.1, the bottom surface of the moving plate 2.1 is connected with a roller 2.2, one end of the moving plate 2.1 is connected with a pulling assembly 2.3, and the other end of the moving plate 2.1 A telescopic spring 2.4 is connected, and the other end of the telescopic spring 2.4 is fixedly connected to the side wall of the fixed seat 1; a waste collection box 2.5 is arranged above the moving plate 2.1, and a fixed plate 2.6 is detachably connected to the bottom of the waste collection box 2.5, which is fixed The plate 2.6 is connected to the mobile plate 2.1 through the swing assembly 2.7;

[0030] ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 1-4 As shown, the pulling assembly 2.3 includes a first rotating motor 2.31, the output shaft of the first rotating motor 2.31 is recessed from both ends to form a winding groove 2.32, and a wire rope 2.33 is connected in the winding groove 2.32, and the other end of the wire rope 2.33 Fixedly connected with the end of the mobile plate 2.1;

[0034]When the present embodiment is used, in the step hole processing process, the first rotating motor 2.31 is started, and the first rotating motor 2.31 rotates so that the steel wire rope 2.33 is wound on the winding groove 2.32, thereby driving the waste collection box 2.5 to approach the first rotating motor 2.31 When the waste collection box 2.5 moves to a certain distance, stop the first rotating motor 2.31, the telescopic spring 2.4 restores its original length, and the telescopic spring 2.4 drives the waste collection box 2.5 to a direction away from the first rotating motor 2.31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com