Drive axle spiral bevel gear near-tooth-shaped forge piece placing supporting plate

A technology of spiral bevel gears and drive axles, which is applied in the field of improvement of placing pallets for driven wheel blanks of rear axles, can solve the problems of not easy stacking, high labor intensity, low labor efficiency, etc., and achieves easy counting and labor reduction. Strength, quick and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

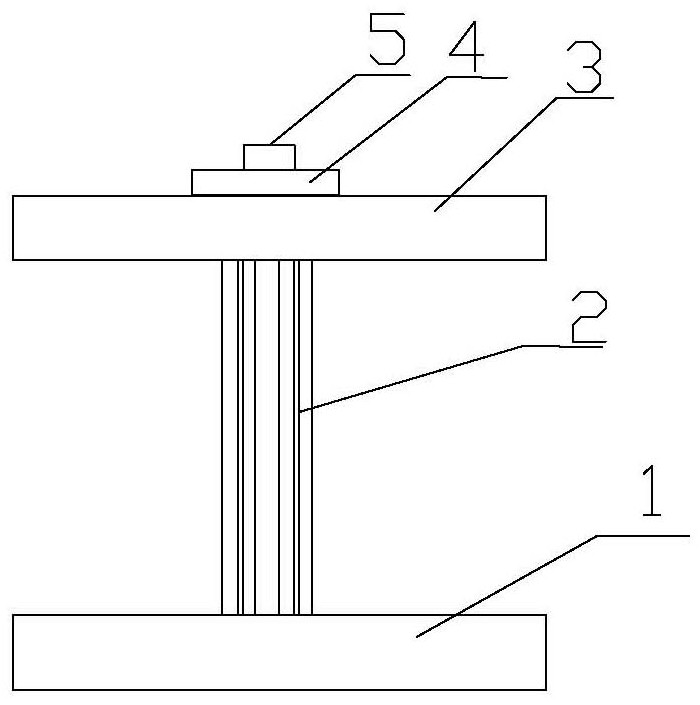

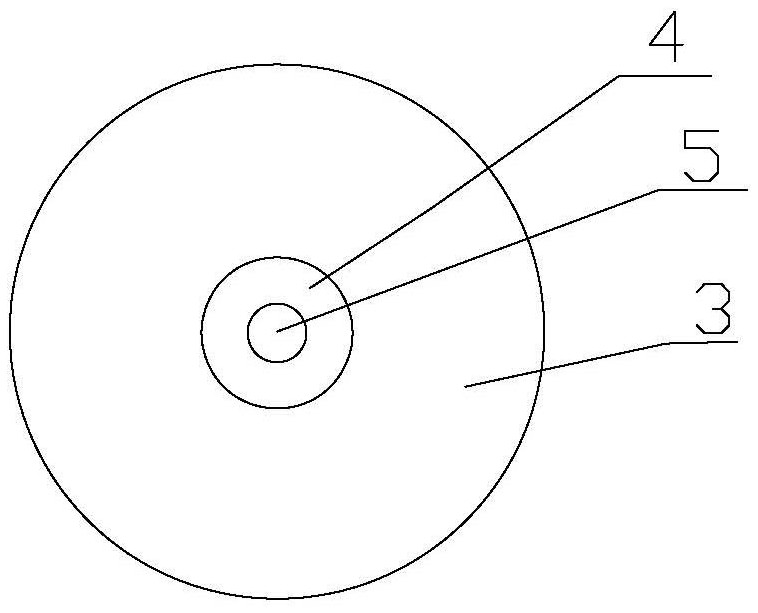

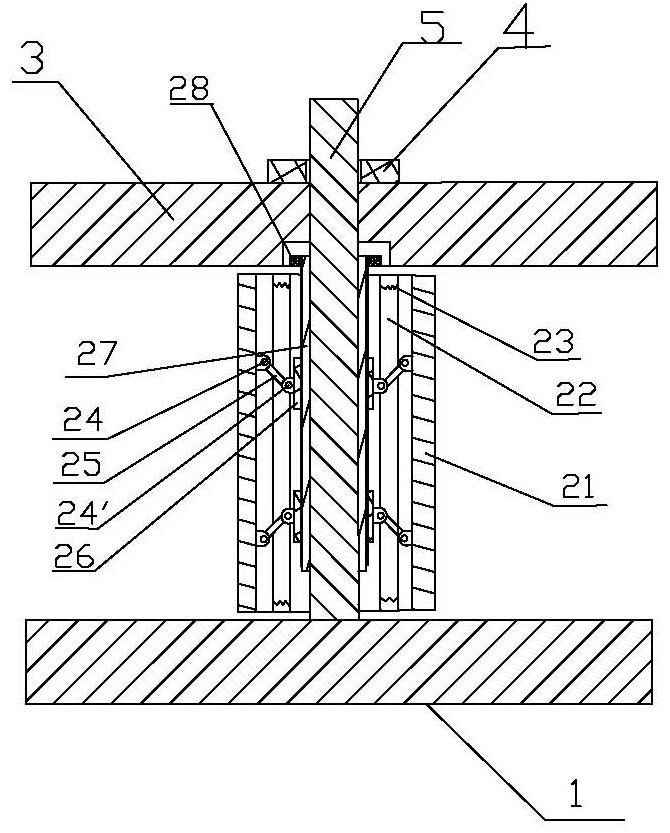

[0012] refer to figure 1 , figure 2 , image 3 , Figure 4 Make the invention. The supporting plate for the near-tooth-shaped forging of the drive axle spiral bevel gear is composed of a placing supporting plate 1, and is characterized in that: the placing supporting plate 1 is a circular plate, and the middle part of the placing supporting plate 1 is provided with an expansion and contraction shaft 2, A detachable disc 3 is set on the upper end of the expansion-contraction shaft 2, and a fastening screw 4 is arranged on the upper end of the fixed shaft 5 of the expansion-contraction shaft 2. The outer diameter of the disc 3 is equal to the outer diameter of the supporting plate 1, And it is 20-40cm larger than the outer diameter of the rear axle driven wheel blank.

[0013] The expansion-shrinking roller 2 is composed of four symmetrical arc-shaped plates 21, the opening and closing seams 22 are formed between the adjacent arc-shaped plates 21, and the ends of the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com