A Fresh Air System for Rapid Replacement and Smoke Exhaust in Environmental Test Chamber

A technology of environmental test and fresh air system, applied in the field of environmental test, can solve the problems of fast gas replacement and high-precision dynamic pressure control, etc., and achieve the effect of simple structure, fast gas replacement and small dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

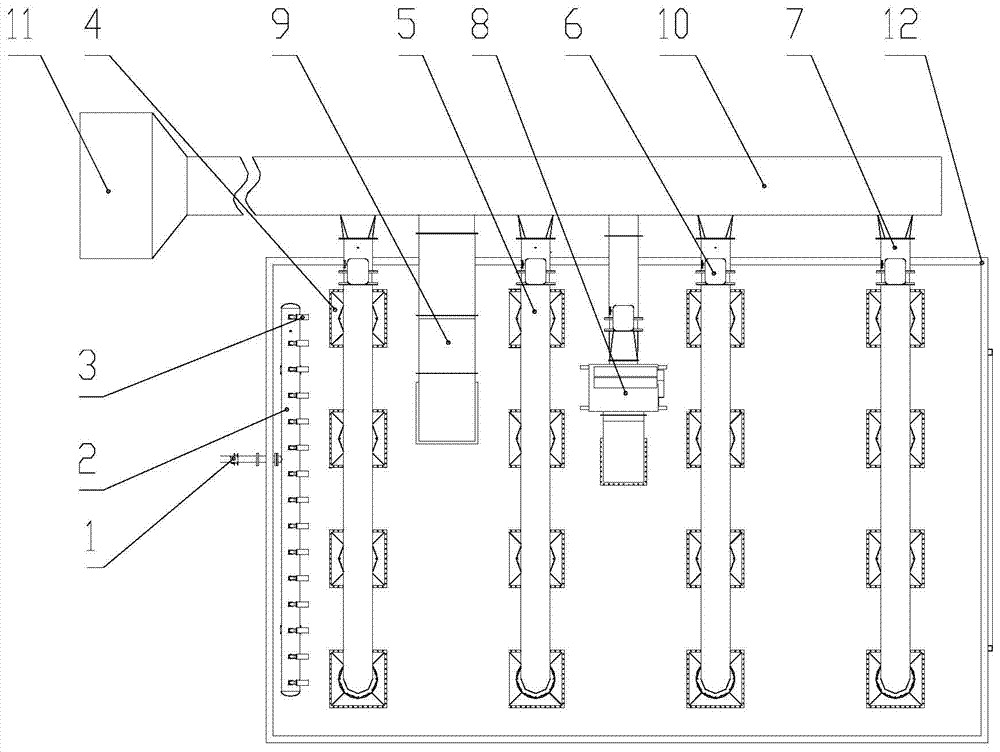

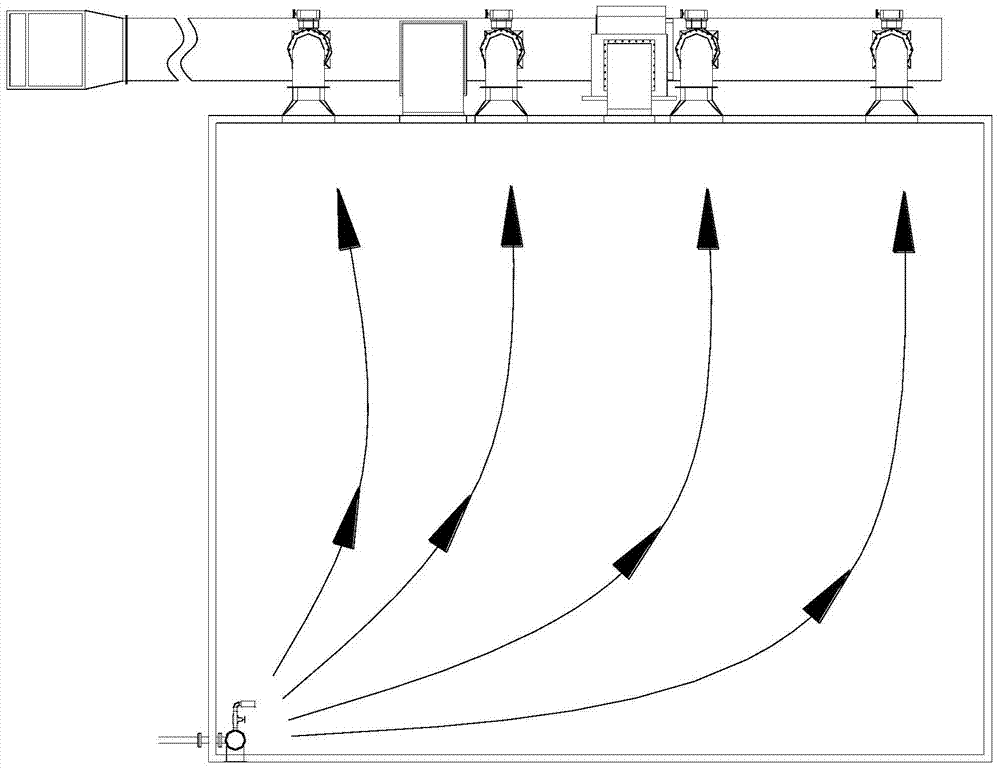

[0037] The following describes a fresh air system for rapid replacement and smoke exhaust of an environmental test chamber according to the present invention with reference to the drawings and specific embodiments:

[0038] A fresh air system for rapid replacement and smoke exhaust of an environmental test chamber, comprising a test chamber body 12, an air intake component and a natural exhaust function component, wherein a part of the air intake component is installed outside the test chamber body 12, and the other part is installed In the test cabin, it passes the replacement gas into the test cabin, decelerates the noise of the gas, and sprays it in the horizontal direction at the bottom of the inner side of the test cabin. The natural exhaust function component is installed in the test chamber to monitor the gas concentration in the test chamber during the test and quickly exhaust it.

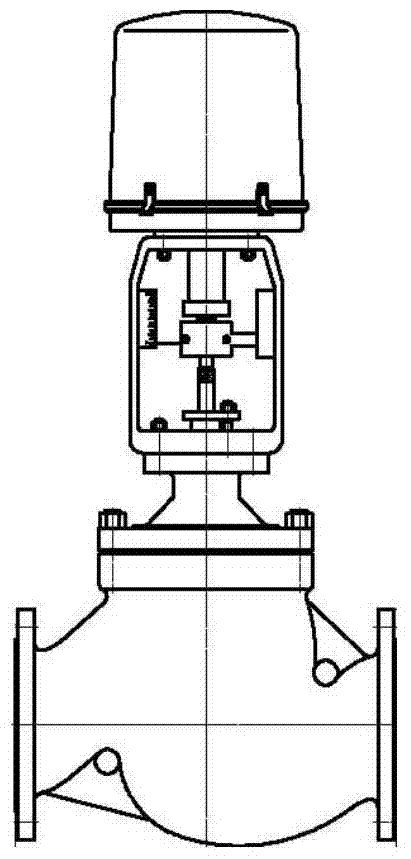

[0039] In this embodiment, the air intake assembly includes an intake air flow regulating va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com