Pulverized coal screening device

A screening device and screening technology are applied in the direction of solid separation, electrostatic effect separation, and separation of solids from solids with airflow, which can solve the problems that the screening efficiency needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

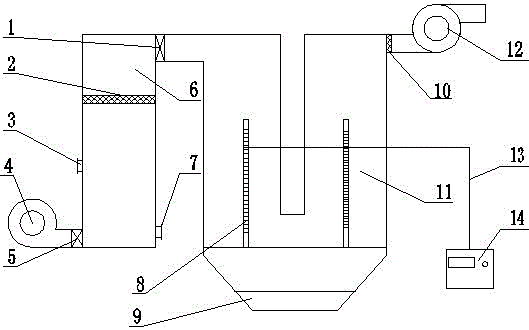

[0005] refer to figure 1 It is as follows: a pulverized coal screening device, which is connected with the screening chamber 6 by the blower 4 through the screening chamber check valve 5, and the upper side of the screening chamber 6 is equipped with a feeding port 3, and the upper feeding port of the screening chamber 6 3 The upper part is equipped with a screen 2, and the lower part of the screening bin 6 is equipped with a slag discharge port 7. The screening bin 6 is connected to the recycling bin 11 through the recovery bin check valve 1, and the recycling bin 11 is equipped with more than one set of electrostatic adsorption devices 8 , the electrostatic adsorption device 8 is connected with the electrostatic recovery control system 14 through the control cable 13, the recovery bin 11 is connected with a diversion fan 12 through the pulverized coal isolation net 10, and the bottom of the recovery bin is equipped with a feeding port 9. When in use, the coal powder to be sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com