Multi-working box sand mould 3D printing equipment

A 3D printing and work box technology, applied in the field of 3D printing, can solve the problems of limited adjustable space, inability to meet production needs, and no simultaneous sand laying and printing of multiple work boxes, so as to reduce the cost of sand molding and improve printing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

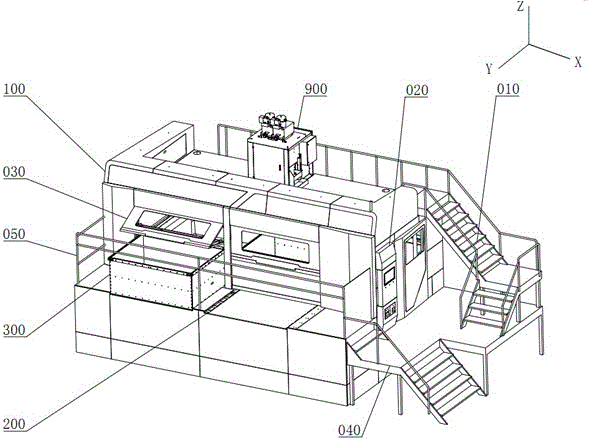

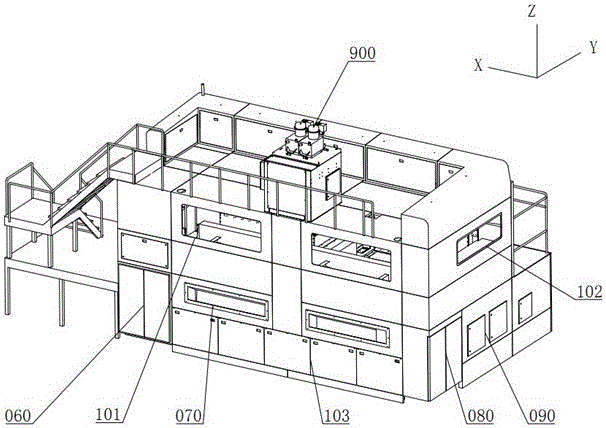

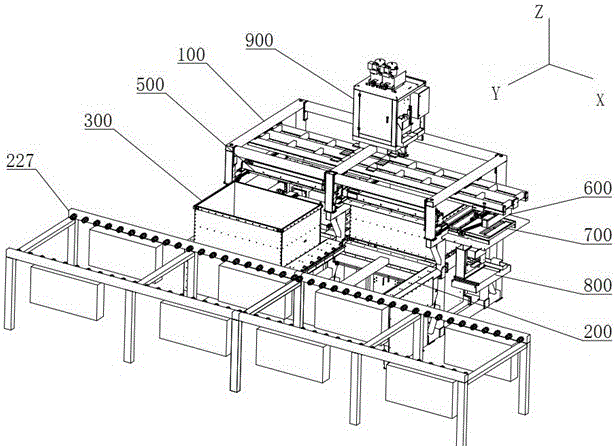

[0050] Overall structure of the present invention is as Figure 1-4 As shown, the multi-box sand mold 3D printing equipment includes: main frame (100), work box conveying system (200), work box (300), work box lifting mechanism (400), sand spreader (500), printing head (600), cleaning device (700), liquid material system (800), sand mixing device (900) and electrical system, wherein the main frame (100) includes at least three columns, and the main frame (100) composed of more than three columns ) After the assembly is completed, more than two independent work areas are formed, and a set of work box jacking mechanisms (400) are respectively installed at the bottom of each work area. A work box conveying system (200) is arranged above the two or more ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com