Metal strip slitting device length adjustment mechanism

A slitting device and length adjustment technology, which is applied to the attachment of shearing machines, shearing devices, metal processing equipment, etc., can solve problems such as complex structures and strips occupying horizontal space on the ground, and achieve the effect of saving foundation construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

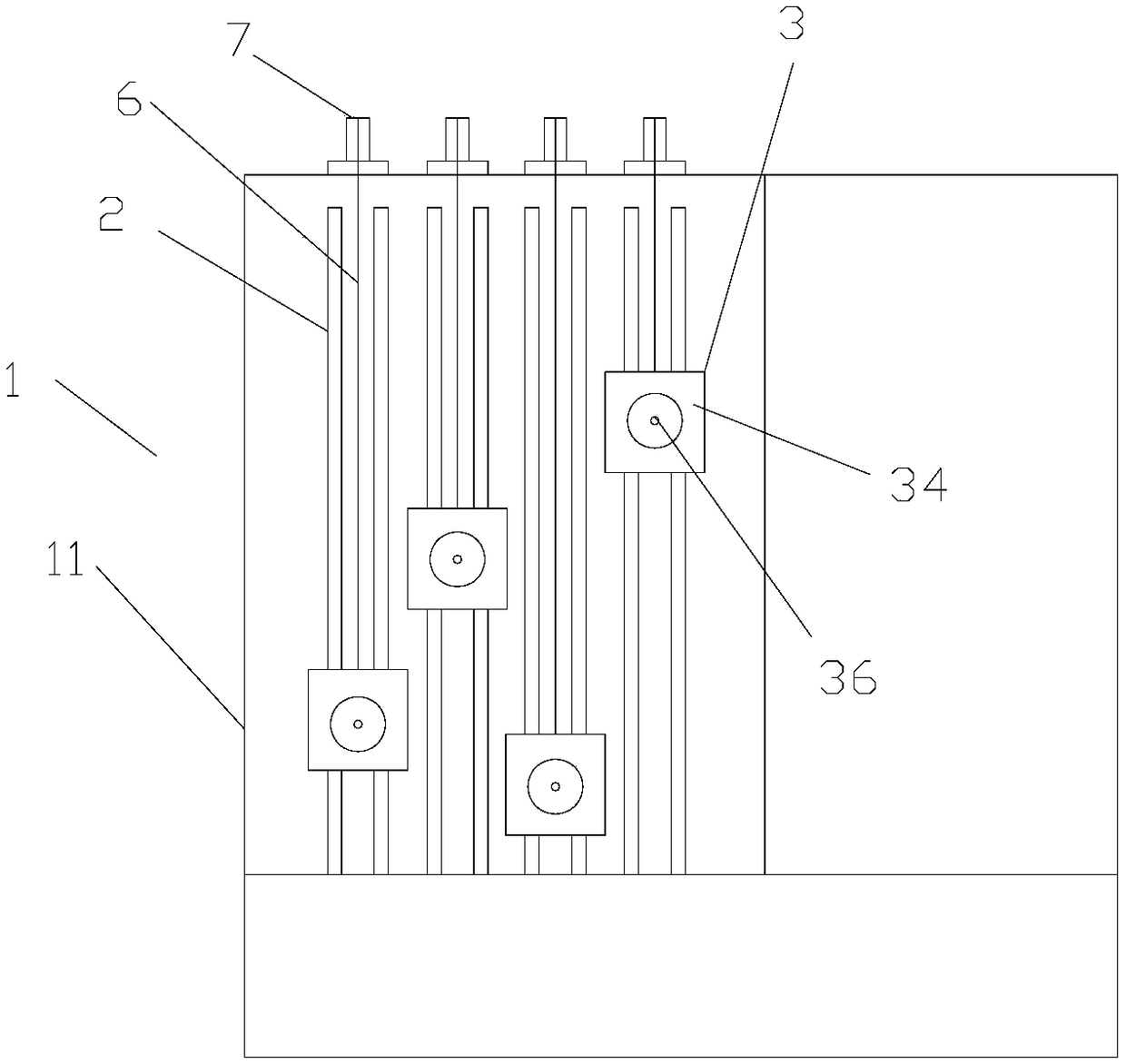

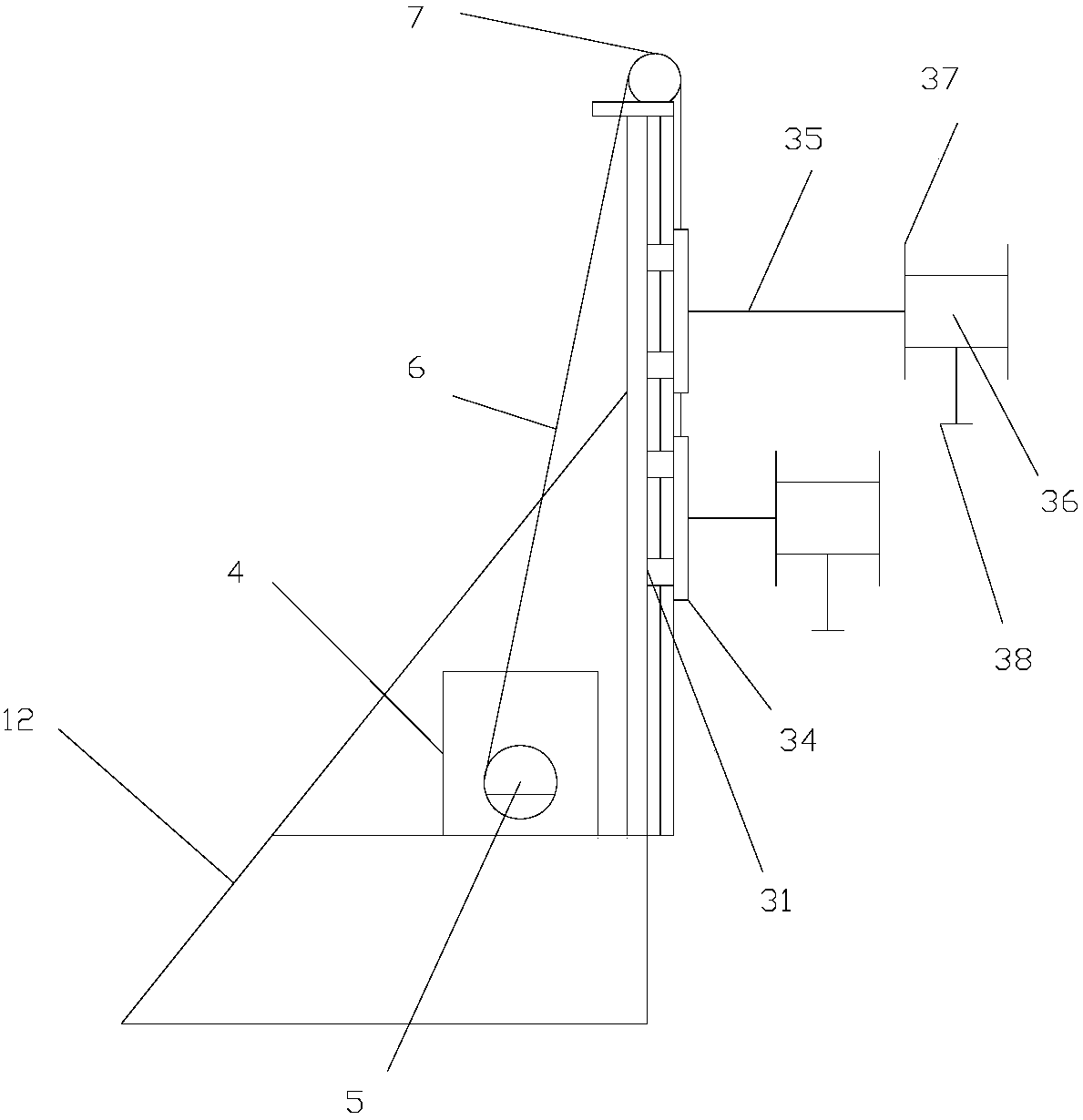

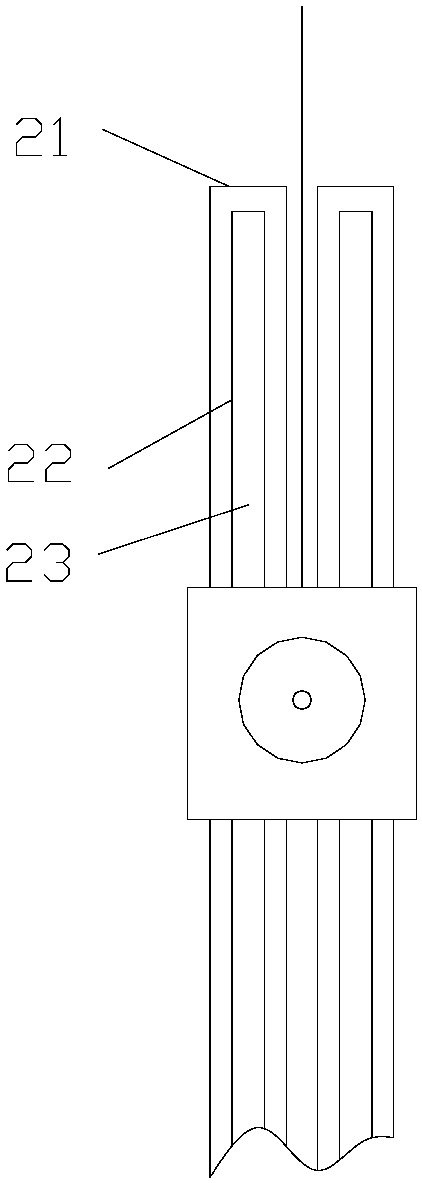

[0026] Please refer to Figure 1-5 , The length adjustment mechanism of the metal strip slitting device provided by the present invention includes a mounting frame 1 on which a vertical slide rail 2 is installed. A strip erecting rack 3 is installed on the slide rail 2, which is used to erect strips processed through slitting. The strip rack is pulled by the traction mechanism, so that it can move up and down on the slide rail 2, and the height position can be adjusted, so that it can be applicable to strips of different production demand lengths. Longer as strip material, then raising strip material puts up frame 3, then reduces strip material and puts up frame 3 as strip material is shorter. After adopting this method, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com