Three-dimensional printer automatic detection device

A 3D printer and automatic detection technology, used in additive processing and other directions, can solve problems such as dislocation, and achieve the effect of simple structure, good limit effect and low labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

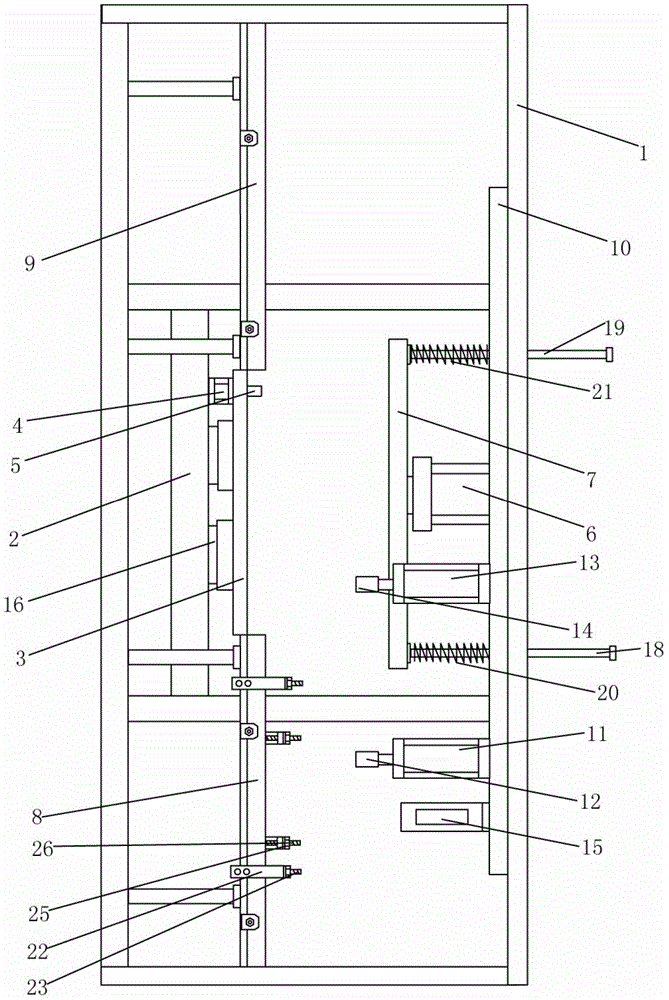

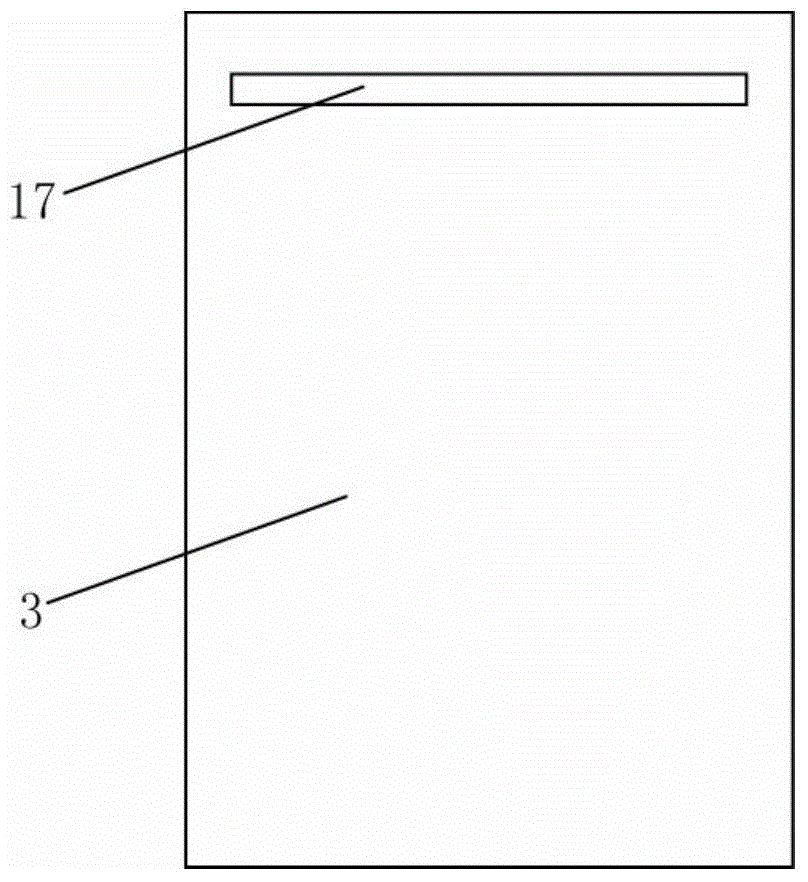

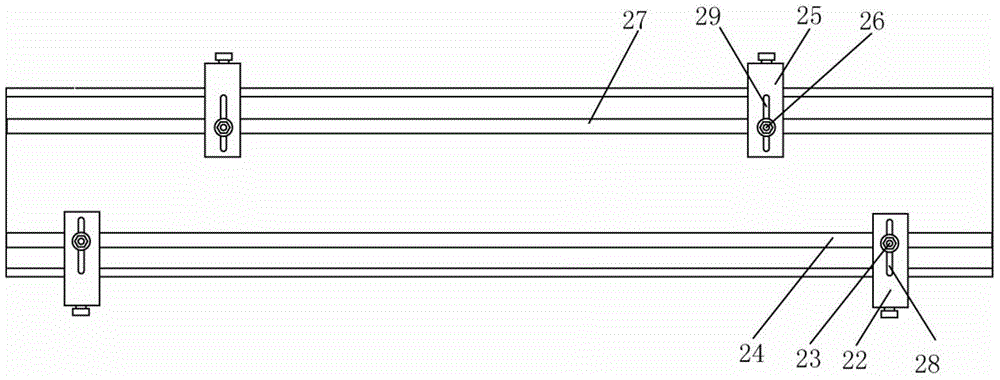

[0023] like Figure 1-3 As shown, an automatic detection device for a 3D printer includes a frame 1, a bottom plate fixing frame 2, a bottom plate 3, a limit plate cylinder 4, a limit plate 5, a top plate cylinder 6, a top plate 7, a feeding and conveying guide rail 8, an output Material conveying guide rail 9, frame sliding guide rail 10, first pusher casing cylinder 11, first push plate 12, second pusher casing cylinder 13, second push plate 14, casing detector 15, first feed conveying Guide rail limit frame 22, first connecting rod 23, first feed conveying guide rail limit plate 24, second feed conveying guide rail limit frame 25, second connecting rod 26, second feed conveying guide rail limit plate 27 , the bottom plate fixing frame 2 is installed on the bottom of the frame 1, the bottom plate fixing frame 2 is equipped with a bottom plate fixing frame slideway 16, the bottom plate 3 is installed on the bottom plate fixing frame slideway 16, and the bottom plate 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com